Cable lugs – Reliable electrical connections for professional installations

Cable lugs enable a secure and permanent connection between cables and connection components. They ensure reliable current transmission, reduce contact resistance and simplify the assembly of electrical connections. The products are available in various designs and cross-sections and are suitable for a wide range of applications in electrical and control cabinet construction.

HELUKABEL cable lugs are manufactured with tight tolerances to guarantee optimal contact, mechanical strength, and long service life - even in demanding industrial environments.

Comprehensive cable lug portfolio

- High-quality copper and aluminum cable lugs compliant with DIN, VDE & UL standards – ensuring safe, durable, and precise connections for industrial and commercial applications.

- Insulated and non-insulated cable lug support a wide range of applications, from control cabinet wiring to power distribution systems.

- Professional installation tools, enabling a complete and reliable termination system.

Contact our HELUKABEL Vietnam engineers to get a quote & expert consultation

HELUKABEL cable lug catalog

1. Compression and tubular cable lugs

Product catalog

2. Ring-shaped lugs

Product catalog

3. Y-shaped lugs

Product catalog

4. Pin cable lugs

Product catalog

5. Butt connectors

Product catalog

6. Crimp cable lugs

Product catalog

7. Bimetallic cable lugs

Product catalog

8. Copper cable lugs

9. Aluminum cable lugs

Compression and tubular cable lugs

Designed to be crimped on to a conductor to facilitate the termination of the cable

via the lug hole

A compression cable lug is larger and longer than a tubular cable lug.

The standard (DIN 46235) specifies the dimensions for all manufacturers of DIN compression cable lugs.

| Compression/tubular cable lugs | Material | Cross-sec. mm² | Stud hole (M) | Characteristics | Part number |

| HELU-S-RK-CU | Copper | 0.75 - 630 | 3 - 20 | Uninsulated Temperature up to +120°C | 907303 |

| HELU-S-RK-90-CU-UL | 6 - 300 | 5 - 20 | 907508 | ||

| HELU-S-RK-45-CU-UL | 10 - 300 | 5 - 20 | 907597 | ||

| HELU-S-RK-CU-UL | Copper | 6 - 500 | 4 - 20 | 907318 | |

| HELU-S-RK-F-CU | Copper | 10 - 240 | 5 - 20 | For finely stranded conductors | 907409 |

| HELU-S-RK-S-CU-UL | Copper | 32 - 240 | 6 - 16 | For switchgear with limited space availability | 90910 |

| HELU-S-RK-N | Nickel | 0.5 - 95 | 4 - 12 | Uninsulated, temperature up to +120°C | 98267 |

Ring cable lugs

Ring-type cable lugs offer maximum connection security by fully enclosing the bolt, ensuring stable performance even under vibration or movement. Featuring a compact, open-front crimp design with a round contact surface, they allow quick installation and reliable electrical contact.

These lugs are widely used in distribution boards, switchgear, and automotive applications where durability and safety are essential.

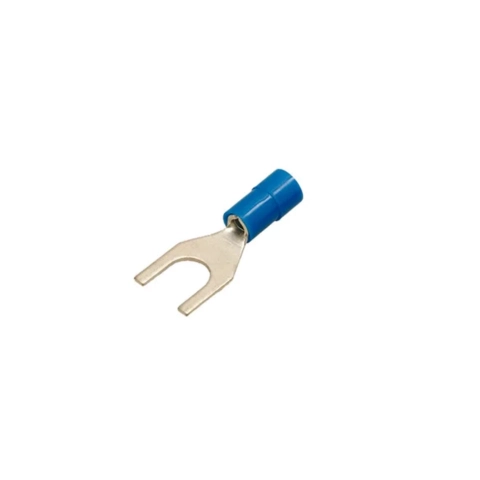

Fork-type lugs

Fork-type lugs enable fast and convenient installation, as they can be positioned under screw terminals without fully removing the screw.

This design saves time during wiring and maintenance, making them a practical choice for control panels and residential electrical circuits.

Pin-type cable lugs

Pin-type cable lugs are designed for push-in connections in terminal blocks or compact electrical assemblies.

They allow fast installation and are commonly used in compact or modular electrical systems where space saving and flexible wiring are required.

The twin version is designed to accommodate two conductors of the same cross-sectional area.

| Pin cable lugs | Material | Cable cross-section (mm²) | Pin length (mm) | Characteristics | Part number |

| B-PF | Copper | 0.5 - 95 | 17 - 55 | Uninsulated, temperature up to +120°C | 91556 |

| ADI-K | Copper | 1.5 - 16 | 17.5 - 25.5 | Many different colors | 91589 |

| ADI | Copper | 0.14 - 150 | 10 - 58 | 91850 | |

| ADI-B | Copper | 0.5 - 2.5 | 14 | 91912 | |

| DUO | Copper | 0.5 - 16 | 15 - 30 | 91622 | |

| ST-RP | Copper | 0.5 - 6 | Halogen-free. Colors: red, blue, yellow | 91422 |

| Bimetallic cable lugs | Material | Cable cross-section (mm²) | Length to centre of hole (mm) | Characteristics | Part number |

| HELU-S-PK-AL/CU | Aluminum 99.5; Copper | 10 - 625 | 50 - 177 | Designed for Conductor type RM and circularly reshaped conductors | 907568 |

| HELU-S-PV-AL/CU | 6 - 400 | 48 - 185 | Press connector for aluminum conductors, strain relieved | 907836 |

Order via HELUKABEL Vietnam E-store

Frequently asked questions about cable lugs

Cable lugs are accessories used to connect or disconnect cables from electrical equipment, busbars, or other connection points, playing a critical role in electrical systems.

They are typically manufactured from copper or aluminum, or their respective alloys, to ensure excellent electrical conductivity and mechanical strength.

Cable lugs simplify the installation, maintenance, and repair of electrical systems. They allow:

- Connect two or more cables together

- Connect the cable to the circuit breaker, fuse holder, and electrical equipment.

- Ensure a secure, stable, and safe electrical connection during operation.

Copper cable lugs are suitable for:

- Copper conductor

- Applications requiring high electrical conductivity

- Control cabinets, switchgear, and industrial electrical systems

Aluminum cable lugs are specifically designed for:

- Aluminum wire

- Preventing contact corrosion when used with the correct conductor material

- Stable operation under thermal effects and varying electrical loads

Bimetallic cable lugs are used when aluminum conductors need to be connected to copper busbars or copper contact points. The bimetal design helps:

- Preventing electrochemical corrosion

- Ensure stable and durable technical connections

- Suitable for electrical systems with different conductive materials