HELUKABEL's cables and wires for cobot and robot applications

1. Cables and wires for robotic applications

1.1 The role of robots

Robots are an essential part of highly dynamic manufacturing industries around the world, and it is difficult to imagine these industries without them. Robots and cobots can be found operating and interacting in close proximity with humans on production lines, but they also perform tasks independently. Modern industrial robots move in three-dimensional space and are able to carry out a great variety of tasks. In doing so, the robot arm repeats a sequence of movements millions of times. It completes repetitive work processes with continuous precision while maintaining consistent quality – without daily variations or signs of fatigue.

1.2 Requirements for cables used in robotic applications

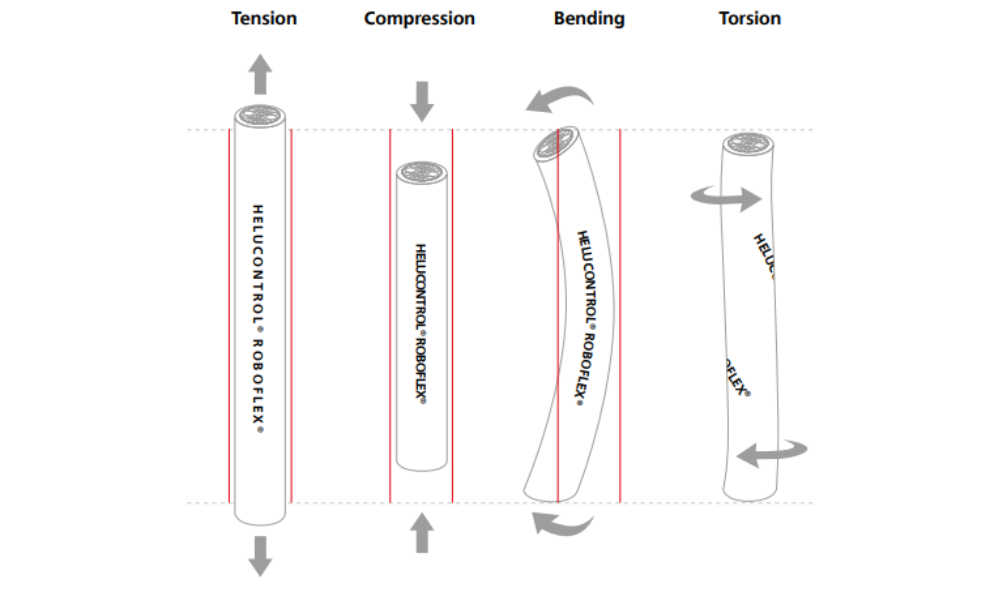

The motion sequences of a robot or a robot arm are repeated millions of times and in all directions. They offer continuous precision and consistent quality for repetitive tasks even under extreme conditions. Strict requirements are placed on robot cables due to strong acceleration and deceleration, loads from tension and 3D stress, a combined stress coming from torsion and bending. They should meet these requirements, but depending on their intended use, they must also be guided in or on the robot arm in a tight and space-saving manner in order to achieve the greatest possible freedom of movement.

In order to be able to do this, the cables in the robots must meet the highest of standards. Rapid acceleration and deceleration, tensile loads as well as combined bending and torsional movements are just a few of the operating conditions taken into account during cable design. At the same time – and depending on the application – space-saving solutions are needed to feed the cables into or along the robot arm whilst maintaining the greatest possible freedom of movement. Mechanical stress as well as chemical and thermal factors often play a role here too.

2. HELUKABEL's cables and wires for robotic applications

2.1 Forces affecting cables and wires in robotics

The cables and wires used in robotics are subject to a variety of forces: the millions of repetitive bending and torsional movements cause high compression and tensile loads, putting considerable strain on the cables. Cable design must also take into account rapid accelerations and decelerations which make high abrasion, notch and tear resistance essential. The high temperatures often encountered in the applications are an additional stress factor.

2.2 HELUKABEL's solutions for robotic applications

With our Roboflex® brand of cables, we have the right solution for a wide variety of applications. Resistance to oil, abrasion, notch and welding beads or extreme bending radii are just some of the requirements fulfilled by our cables.

HELUKABEL’s assortment of cables for robotic applications includes control and motor cables of many different dimensions, hybrid cables and cables for the sensor and data, network and bus technology sectors. In addition to high levels of stock availability, HELUKABEL also offers bespoke solutions and develops cables tailored to your application.

We are also able to provide customised, assembled and ready-to-install dresspacks through our one-stop shop supplier and subsidiary, Robotec-Systems GmbH.

3. HELUKABEL's cables and wires for robot and cobot applications

3.1 Data cables

HELUDATA® ROBOFLEX® PUR UL/CSA

HELUDATA® ROBOFLEX®-D PUR UL/CSA: có khả năng chống nhiễu

HELUDATA® ROBOFLEX®-PAIR-D PUR UL/CSA: chống nhiễu

HELUDATA® ROBOFLEX® 2001

HELUDATA® ROBOFLEX® 2001-D

3.2 Control cables for robotics

Some types of control cables for robotic applications:

HELUCONTROL® ROBOFLEX® PUR UL/CSA

HELUCONTROL® ROBOFLEX®-D PUR UL/CSA

HELUCONTROL® ROBOFLEX® 2001

HELUCONTROL® ROBOFLEX® 2001-D

Some types of HELUPOWER® control cables:

HELUPOWER® ROBOFLEX® PUR UL/CSA

HELUPOWER® ROBOFLEX® PUR UL/CSA

HELUPOWER® ROBOFLEX®-D PUR UL/CSA

HELUPOWER® ROBOFLEX® HYBRID PUR UL/CSA

HELUPOWER® ROBOFLEX® HYBRID-D PUR UL/CSA

3.3 Welding spark resistant sensor cables

Nowadays industrial robots are in a position to take over the broadest diversity of manufacturing tasks. Welding has always been one of the classic applications. Here, as in many other areas of production, the topic of "precision" is decisive: robots always deliver the same quality weld seam – and that’s with shorter cycle times, without high temperatures and without the emission of toxic gases and fumes that pose a risk to health. However, the benefits of highly automated processes can only be fully exploited if the reliability of all the components is also guaranteed.

With our HELUDATA® ROBOFLEX®-recycle cable, we offer you the right solution for usage in welding robots. The material was developed and tested at our production facility in Windsbach and its verification complies with the latest version of the standard developed by the Volkswagen Group for measuring the resistance of cables to welding sparks. With this innovative material – which doesn’t use crosslinking – we achieve excellent resistance to welding sparks. At the same time, it’s completely recyclable – unlike conventional cross-linked thermoplastic elastomers which contaminate our environment to a large extent. This will be of particular interest to customers with a DIN EN ISO 14001 compliant environmental management system and therefore place great value on the use of recyclable materials.

Benefits of using HELUDATA® ROBOFLEX®-recycle cables

- Saving money over cross-linked cables

- Halogen-free

- Heat-resistant from -40°C bis 105°C

- Good resistance to oil, chemicals and welding sparks

- UL and CSA approval

- Suitable for drag chains and robots, tested with 10 million changing bending and torsion cycles

3.4 PROFInet and BUS cables

HELUKAT® PROFInet R+ CAT.5e SF/UTP PUR ROBOTIC

HELUKAT® 100T CAT.5 SF/UTP PUR TORSION

HELUKAT® 600T CAT.7 SF/FTP PUR TORSION

HELUKABEL® BUS Cables Profibus L2 Torsion

HELUCOM® I-V4Y(ZN)Y (B) and I-V4Y(ZN)11Y (C)

A-V(ZN)11Y