Overview of cvv cable

What is cvv cable?

Cvv stands for CU/PVC/PVC, a type of electrical cable designed with a core made of multiple strands of pure soft copper, insulated with PVC material, and covered with PVC sheath. Widely used in civil power grid systems, the characteristic of cvv is its ability to transmit stable voltage for low-voltage electrical lines. Cvv cables come in various types. Some common types of CVV cables include:

- Cvv 2-core cable.

- Cvv 3-core cable.

- Cvv 4-core cable.

- Cvv 3+1; 4+1 cable.

Structure of cvv cable

CVV cables are formed by combining multiple twisted soft copper conductors, insulation, and PVC sheath:

- Conductor core made of pure copper.

- Insulation using PVC material.

- Filler layer may be made of PP wound with PET or PVC.

- Outer sheath is made of PVC.

Outstanding features of cvv cable

The distinctive structure of the cvv cable endows it with several advantages, including:

- Stable performance: Cvv cable is designed with a conductor core made of pure copper, ensuring high electrical conductivity and stable signal quality.

- Durability: The insulation layer made of PVC material protects the conductor core from the influence of external factors such as moisture and temperature, ensuring the cable's safety during use. Additionally, the high-quality PVC outer sheath enhances flexibility and ensures the cable's durability in harsh environments.

- Versatility: Cvv electrical cables can meet various requirements and are widely used in civilian power transmission systems, low voltage, medium voltage, and industrial applications. Moreover, the flexible design of cvv cable facilitates easy installation and maintenance in electrical systems, reducing costs and deployment time.

Overview of cxv cable

What is cxv cable? Structure of cxv cable

Cxv cable is a specialized type of cable for low-voltage electrical systems with the capability to transmit voltage levels of 0.6/1kV. The structure of cxv cable includes a conductor core made of multiple strands of high-purity, soft-grade copper (class 2), insulation made of XLPE, and an outer sheath made of PVC. The components of cxv cable structure are as follows:

- Conductor core: The cable's conductor core utilizes high-purity solid copper, enhancing its conductivity and minimizing energy loss.

- Insulation layer: The insulation layer of cxv cable is made from XLPE material, providing excellent heat resistance and high dielectric strength, ensuring safe insulation.

- Filler layer: The filler layer can be made from PVC or PP wrapped with PET.

- Outer sheath: The outer sheath of cxv cable is made from high-quality PVC, capable of withstanding high temperatures and protecting the cable from environmental influences.

Outstanding features of cxv cable

Prominent advantages of the cxv cable:

- Excellent conductivity: The conductor core of the cxv cable is manufactured from high-purity copper, providing optimal conductivity. This helps maintain stable performance during electrical transmission.

- Heat resistance: The XLPE insulation layer not only offers high heat resistance but also maintains excellent dielectric strength, ensuring the safety and stability of the system.

- Fire resistance: The PVC outer sheath of the cxv cable possesses effective fire resistance, enhancing safety in the operating environment.

Applications of cvv cable and cxv cable

Cvv and cxv cables have various specific applications, including:

- Electricity and energy infrastructure: Cvv cables are commonly used to connect transformers, control systems, and automation in ensuring the stable and safe transmission of electrical power from the source to consumer units. Additionally, cvv cables play a crucial role in providing power to street lighting systems, public lights, and other consumer devices in public areas.

- Construction: cvv cables find applications in control and automation systems in construction projects, where signal transmission and data play a vital role in managing and controlling various electrical devices and systems. Especially in large construction projects such as shopping malls, urban areas, or industrial facilities, cvv cables are the top choice due to their high durability, reasonable price and stable power transmission capabilities.

- Automation: Specific applications include using cvv cables to connect Programmable Logic Controllers (PLC), measuring and control devices, ensuring efficient operation in automated manufacturing systems. Additionally, cvv cables are often applied to transmit data from sensor devices to control centers, providing flexibility and synchronization in industrial automation processes.

With your technical concern, please contact us via:

| Phone | +84 28 77755578 |

| info@helukabel.com.vn | |

| Zalo Official Account | Zalo HELUKABEL Vietnam |

| Technical data of our products | PRODUCT FINDER |

CONTACT US AT HELUKABEL

CONTACT US VIA ZALO

MESSAGE

GET IN TOUCH WITH US

CONTACT FORM

OFFICIAL E-STORE OF HELUKABEL VIETNAM

DISCOVER E-STORE1. HELUKABEL's cvv cable

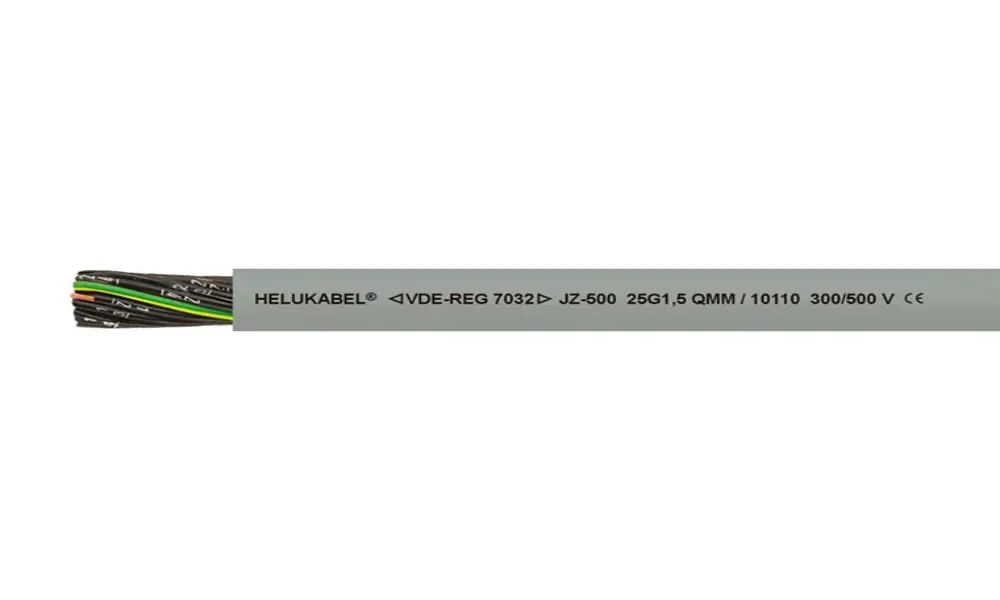

1.1 JZ-500

Temperature range

- Flexible: -15°C to +80°C

- Fixed: -40°C to +80°C

Nominal voltage: AC U0/U 300/500 V

Test voltage core/core: 4000 V

Breakdown voltage: 8000 V

Minimum bending radius:

- Flexible: 7.5x Outer-Ø

- Fixed: 4x Outer-Ø

Data sheet of JZ-500

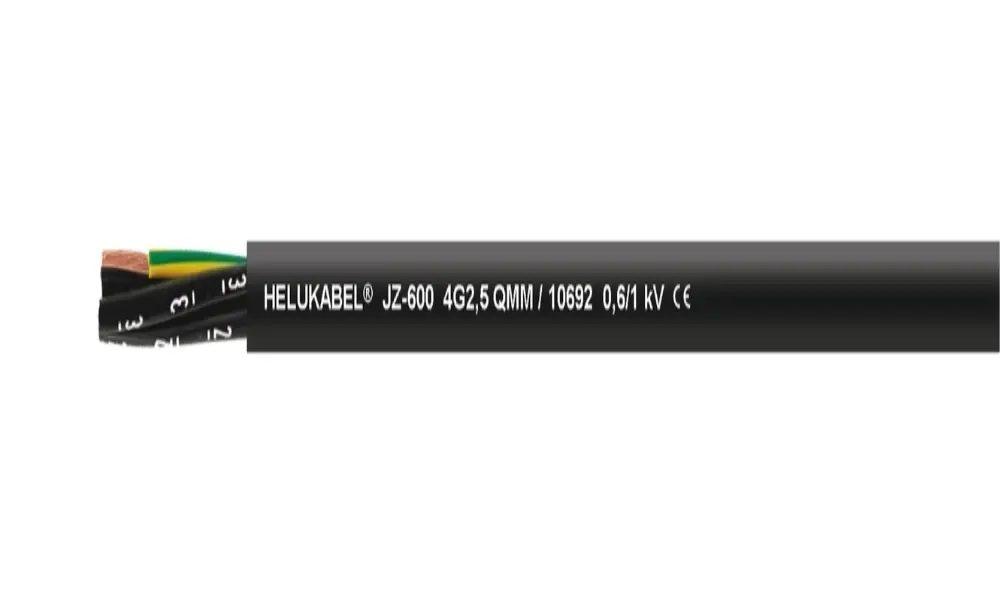

1.2 JZ-600

Temperature range

- Flexible: -15°C to +70°C

- Fixed: -40°C to +80°C

Nominal voltage: AC U0/U 600/1000 V

Test voltage core/core: 4000 V

Breakdown voltage: 8000 V

Minimum bending radius:

- Flexible: 7.5x Outer-Ø

- Fixed: 4x Outer-Ø

Data sheet of JZ-600

-grey-2-x-1.5-mm²_post_detail_picture.webp)

3. TRONIC (LiYY)

Temperature range:

- Flexible: -5°C to +80°C

- Fixed: -40°C to +80°C

Peak operating voltage:

- 0.14 mm²: 350 V

- 0.25 - 1.5 mm²: 500 V

Minimum bending radius:

- Flexible: 7.5x Outer-Ø

- Fixed: 4x Outer-Ø

Data sheet of TRONIC (LiYY)

2. HELUKABEL's cxv cables

2.1 HELUDATA® EN-50288-7 XLPE/PVC OSA 500

Temperature range:

- Flexible: -5°C to +50°C

- Fixed installation: -30°C to +90°C

Nominal voltage: U AC 500 V

Test voltage:

- Core/core: 2000 V

- Core/screen: 2000 V

Minimum bending radius: Fixed: 10x Outer-Ø

Data sheet of HELUDATA® EN-50288-7 XLPE/PVC OSA 500

2.2 HELUDATA® EN-50288-7 XLPE/PVC IOS 500

Temperature range:

- Flexible: -5°C to +50°C

- Fixed installation: -30°C to +90°C

Nominal voltage: U AC 500 V

Test voltage:

- Core/core: 2000 V

- Core/screen: 2000 V

Minimum bending radius: Fixed: 7,5x Outer-Ø

Data sheet of HELUDATA® EN-50288-7 XLPE/PVC IOS 500

2.3 N2XH-O black 2 x 1,5 re mm²

Temperature range:

- During installation: -5°C to +50°C

- Fixed installation: -30°C to +90°C

Nominal voltage: U0/U 0,6/1 kV

Test voltage: 4kV

Minimum bending radius:

- single-core 15x cable Ø

- multi-core 12x cable Ø

Data sheet of N2XH-O black 2 x 1,5 re mm²