HELUKABEL CUSTOM CABLES FOR INDUSTRIAL SECTORS

For large-scale operations and complex electrical systems in the industry, industrial cables must perform their functions efficiently. These cables are designed to ensure stable signal and energy transmission between devices and machinery in the factory. At the same time, electrical cables are required to have a strong outer shell or good noise protection layer to avoid interference and external environmental effects

Electrical cables are increasingly important in all industrial sectors. However, not all cables are suitable for all industries. Specific industries with harsh operating environments require electrical cables that are compatible and adaptable to changing production conditions.

For example, in steel production plants, both machinery and humans must operate at high temperatures and come into contact with hazardous chemicals. For all electrical systems, machinery, and equipment in the factory to operate smoothly, electrical cables must withstand heat and resist corrosion from harmful substances such as oil, acid, and alkali.

In addition, in outdoor installations, selecting cables with appropriate structure and cross-section for outdoor conditions is very important as this will determine whether the cables operate effectively or not. From the above requirements, custom cables (or customized cables) have been developed with parameters, materials, and structures adjusted to provide suitable features for specific environments.

If you need to use custom cables for your projects or constructions, HELUKABEL Vietnam can help you with a team of experienced and professional engineers. We are ready to provide effective and optimal solutions for each specific project. In addition, our diverse product range allows us to quickly customize electrical cables and meet international quality standards such as VDE, UL, IEC, and TUV...

The tests we have performed include:

1. Bending test

This test checks the bending strength to evaluate the mechanical strength of electrical cables under bending stress. We use our own testing equipment to simulate different loads and radii of curvature to ensure that our products can withstand pressure and deformation in daily applications, thus significantly reducing cable breakage, especially at weak load-bearing points.

2. Torsion test

We, HELUKABEL, also perform tests on the ability of cables to withstand torsional forces to detect potential risks that can cause cable breakage or transmission problems in applications that require high torsional forces. This helps ensure that custom cable products always meet quality standards and operate efficiently.

Torsion testing is often necessary for cable types used in industrial robotics.

3. Abrasion test

Contact with the external environment can cause cable abrasion leading to cable breakage, short circuits, and even fires. Therefore, we have conducted tests to evaluate the degree of wear resistance of materials before they are released to the market.

4. Cable twist test for wind energy

Electrical cables in wind turbines must also withstand strong torsion. This can cause both mechanical and electrical functions to degrade over time. Therefore, we test the cable's ability to resist torsion to prevent potential problems that may occur during use.

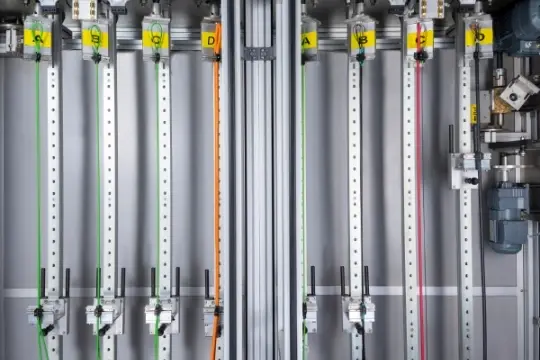

5. Drag chain test

Cable chains always move with high acceleration, narrow radii of curvature, and continuous wear. We use a cable chain testing system to test the cable's operating level in different simulated scenarios. This ensures that cables used in cable chains have good operational capabilities under continuous movement conditions.

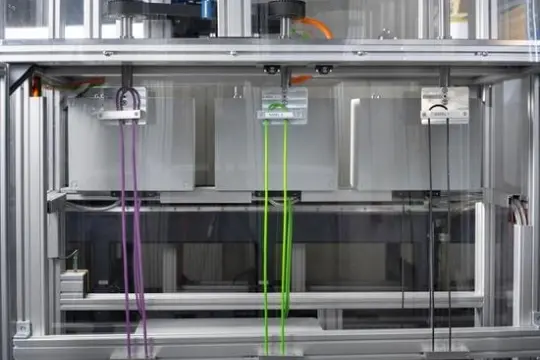

6. Torsional twist test

There are applications where electrical cables must come into contact with torsional and bending movements at the same time. For this reason, we perform torsional twist tests. This is a twisting and bending test with a special cable chain that simulates the impact of loads in high dynamic applications.

In addition to the tests mentioned above, we, HELUKABEL, also meet other specific test requirements of customers. With a team of experienced engineers specializing in designing and developing electrical cables, you can be assured that custom cables are not only suitable for projects but also meet international quality standards.

Call +84 28 77755578 or email us at info@helukabel.com.vn or register for free advice on control cables, signal cables... with specialized engineers using the form below.