KABELMAT CABLE WINDING TECHNOLOGY FOR INDUSTRIAL SECTORS

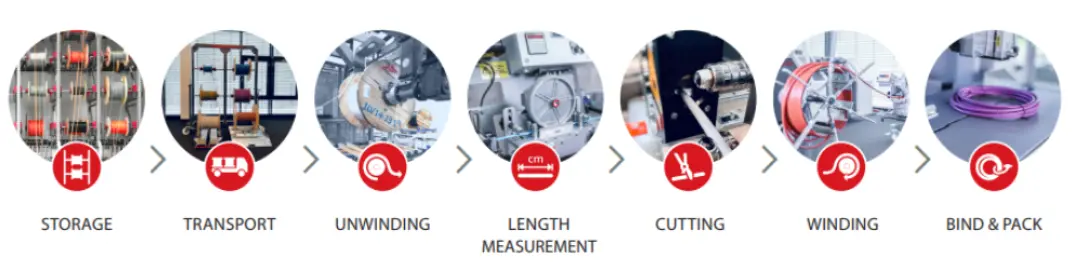

During the installation of electrical cables in construction projects or in cable manufacturing plants, cable winding technology plays an important role in saving time, effort, and especially enhancing aesthetics.Kabelmat is a group that has cable winding technology since the 60s and is also a subsidiary of our HELUKABEL group. Kabelmat uses a flexible production system, supported by modern CNC control machines and ERP. With a carefully invested production facility and machinery system, we can design, produce and supply products to customers in the best time frame.Kabelmat's product portfolio includes several areas:

- Machine winding technology as well as complete machine lines

- Manual winding technology

- Linear encoders

- Storage systems for cable drums/ coils and cable rings

- Cutting Systems

- Distributors

Please call +84 28 77755578 or email us at info@helukabel.com.vn or register for free consultation via the form below to get advice on control cables, signal cables... with specialized engineers.

Contact our HELUKABEL Vietnam engineers to get a quote & expert consultation

KABELMAT product line

1. Manual winding

Discover our products

2. Coil và spool winder machine

Discover our products

3. Pintle winder/unwinder for coils and drums

Discover our products

4. Winding line with automatic drum pick-up

Discover our products

5. Winding line for big-sized drums

Discover our products

6. Length measuring systems

Discover our products

7. Storage system for coils, tubes and plastic pipes

Discover our products

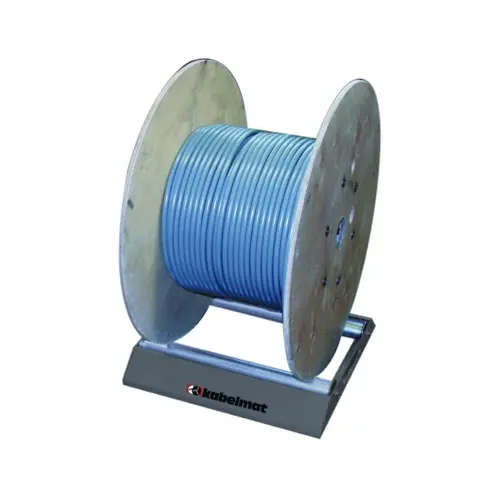

8. Cable drum storage systems

Discover our products

9. Cutting systems

Discover our products1. Manual winding systems

Manual winding systems

These are non-motorized winding and unwinding devices.

KABELMAT offers a wide variety of designs and sizes for both winding and unwinding machines, suitable for various types of cable drums and coils.

| Products | Descriptions |

| MESSROL 450 | Rewind coils and spools while simultaneously measuring |

| MESSROL 670 / 1000 | Manual winding, measuring and cutting |

| MESSROL 500 | Manual winder with a lot of working surface |

| TISCHROL 1000 | Practical table or stand winder |

| KOMBITRAK 800 | For heavy coils and spools |

| RINGO 500 | Perfect for building site Compact design |

| TROMBOI 500 / 800 / 1400 | Cinoact design, Manual drum unwinder for drums from 140 to 1500 kg |

| TROMBOI 7-10 / 9-14 | Manual drum unwinder for drums max. 1000 kg / max. 1700 kg |

| TROMBOI 2003 | Manual drum unwinder with hydraulic hand pump for drums max. 4000 kg |

| TROMTRAK 1250 | Manual drum unwinder with adjustable brake |

| TROMCAR 1000 / 1250 | Manual unwinder and transport device for drums |

Coil, spool and drum winder/unwinder

The motor-driven coil and pipe winder allows winding materials such as electrical cables, pipes, hoses, steel cables, and plastic profiles onto coils or hollow spools. At the same time, the machine can accurately measure length and perform cutting directly during the winding process.

| Type | Products | Features |

| Length cutting machine | AUTOCUT 40 | Easy operation - Exact cutting Cutting machine for cables, pipes, hoses and more |

| Coil, spool and drum winder | MOTROL500/800/800 EASY/1000 | Coil and spool winding machine for coiler head / spool-Ø max. 500/800/1000 mm |

| Coil winder / Pipe winder | RINGROL 300/400 / 560 | fully automatic ring and coil winder up to outer ring Ø max. 300mm / 400 mm / 560 mm |

| RINGROL 600/800 | Semi-automatic coil winding machine for coil-Ø max. 600/800 mm | |

| RINGROL 1200 | High outputs, Short changeover times - Fully automated coil winding | |

| Drum unwinder | TROMTRAK 1250 MOT | Motorised unwinder for drums up to outer Ø max. 1250 mm |

| TROMTRAK 1600 | Electrohydraulic unwinder for drums max. 3000 kg | |

| TROMROL 2500 | Electrohydraulic unwinder with axle and disk brake for drums up to 5000 kg | |

| Coil and spool unwinder | SPULFIX 480 | Perfect complement to processing machines |

| Cable sinter machine | SIGNOMAT | Permanent label print on cables and wires |

| Feeder | AUTOFEED 500-90 / 280-40 | Pneumatic belt feeder |

| ROLFEED 25 MAN / 40 MOT | Manual roller feeder |

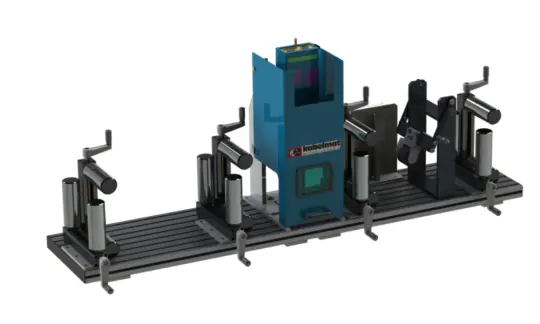

Pintle winder/unwinder for coils and drums

With the motor-driven pintle winder for drums and rings, winding materials can be wound and, with the appropriate accessories, simultaneously measured to length and cut. Convinces with simple operation at the touch of a button

| Products | Features | |

| Pintle winder for coils and drums | UMROL 1000 AUF | Winding big drums at the touch of a button |

| UMROL 1400 / 1600 / 2200 AUF | High level of security and defined working areas | |

| PORTROL 1000 / 1400 AUF | Cut at the touch of a button | |

| Pintle unwinder for drums | PORTROL 1000 / 1400 ABW | Drum unwinder with material accumulator |

| UMROL 1000 / 1400 / 1600 / 2200 ABW | Motor-driven pintle unwinder for drums and rings up to max. outer Ø 1000 / 1400 / 1600 / 2200 mm | |

| PORTROL 1600 / 2200 / 2800 / 3000 ABW | Motor-driven pintle unwinder for drums up to max. outer Ø 1600 / 2200 / 2800 / 3000 mm |

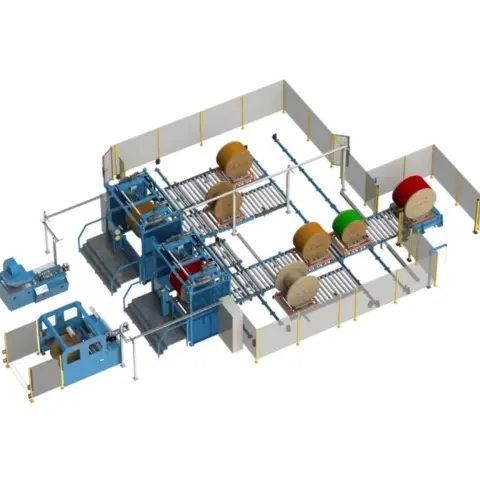

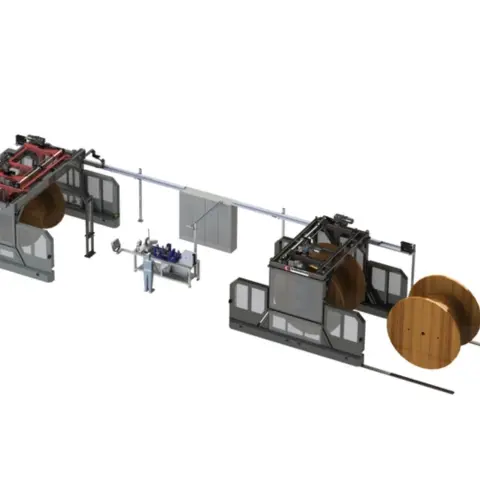

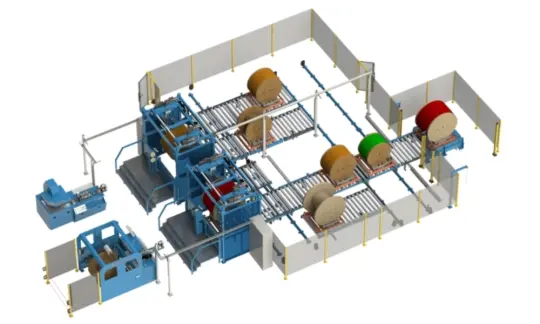

AUTOLOG - Winding line with automatic drum pick-up

The AUTOLOG rewinding line with automatic drum pick-up enables desired lengths to be unwound from the source drum and wound onto the target drums, measured and cut - all fully automatically. Thanks to the connection to a fully automated warehouse, even the transport of the drum to the length cutting machine is possible without any problems.

There are 2 different systems:

- System 1: Machine to drum: It is used where rela-tively low numbers of cuts and few members of personnel are required.

- System 2: Drum to machine: Clearly structured material flow. Clear winding pattern at high speed

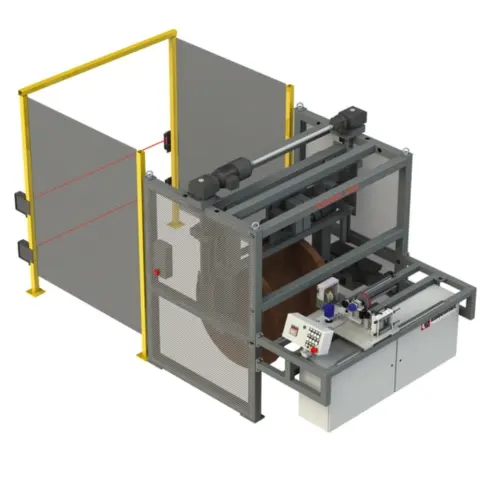

Winding line for heavy drums

Winding line in the heavy-duty range for cutting and wrapping winding materials for the transmission of high energies, as well as for the transmission of data involving copper and fibre optics. Ideal for use with large diameter drums and long cutting lengths.

Portal unwinder PORTROL 3000

- Mobile version for easy handling and installation of heavy drums

- Telescopic arms for lifting and positioning drums

- Frequency-controlled winding drive with AC motor

- Safety laser scanner to protect the work area

- Integrated equipment table with MESSBOI 100 length measuring device, cutting knife, and guiding system

Portal unwinder PORTROL 2600

- Mobile version for easy installation of heavy cable drums

- Telescopic arms for lifting and handling drums

- Frequency-controlled winding drive with AC motor

- Safety laser scanner to protect the work area

- Traversing unit to ensure precise winding of the material

Lenghth measuring systems

Our length measuring devices are available in various designs and sizes, depending on the maximum diameter of the material to be measured.

These devices are equipped with either a mechanical counter or a digital electronic counter with a display. The electronic counter integrates two signal outputs: a pre-switch contact for smooth reduction of the winding speed, and a limit contact that serves as a stop signal for the winding drive.

The length measuring devices can be used independently in practice or in combination with the MESSROL, MOTROL, UMROL, and PORTROL series.

| Products | Features |

| MESSBOI 10 | Mechanical length measuring device for winding material-Ø max. 15 mm |

| MESSBOI 25 | Mobile as a hand-held device or stationary use |

| MESSBOI 40 B LC / LC-MID | Digital belt length measuring device for winding material-Ø max. 40 mm |

| MESSBOI 40 BAE | Mechanical length measuring with modular design |

| MESSBOI 40 LC / LC-MID | Data storage for a permanent and tamper-resistant storage of all measurements |

| MESSBOI 80 LC / LC-MID | Length measuring for big sizes |

| MESSBOI 100 LC / LC-MID | Length measuring device for big material |

| MESSBOI 100 LASER | Contactless length measuring |

Storage and unwindig system for coils, tubes and plastic pipes (MATBOI / SPULBOI)

The stationary or mobile unwinding and storage system cable rings, tubes and plastic pipes with a compact, clear, space-saving and useful design. The complete system include:

- Storage rack / Wall profile rail

- Coil storing units - horizontal: MATBOI 200 T, MATBOI 300 T, MATBOI 450 T

- Length measuring devices: MESSBOI 10 H, MESSBOI 25

- Bouncing protection, accessories

Cable drum storage systems

The stationary unwinding and storage system enables space-saving storage of drums with variable individual components and loading options. The rack allows the winding material to be unwound directly from the stored drum, saving time, storage space and personnel costs.

| Sản phẩm | Đặc điểm |

| LAGBOI 2200 / 3000 | The LAGBOI consits of pre-assembled modules (frame and crossbars) and can be assembled to a solid, clearly ordered, space-saving and very useful rack and unwinding device. The system is only suitable for manual unwinding |

| ABROL | Heavy-load drum rack and unwinding system for big drums up to 5000 kg |

| LAGROL | The LAGROL drum rack segments consist of two frames each of appropriate height, the necessary cross connectors for the respective segment load as well as of the axle holding fixtures and the axles for the drums. For each further segment only an additional frame is required and the corresponding number of cross connectors, axle holding fixtures and axles. The system is suitable for manual and motorized winding |

| TROMBULLY | Multifunctional and space-saving drum take-off unit with central take-off point. Low overrun of the drums due to adjustable brake. The ideal system in combination with a motorised wrapping or cutting machine. |

Cutting systems

- MATIS - Manual cutting unit: Manual cutting units for effortless, clean and smooth cuts including non-slip handle and great leverage

- MATIS - Pneumatic cutting unit: Pneumatic cutting units are characterised by high cutting frequencies and are mainly used in semi-automatic length cutting machines. The cutting process is triggered by a button or via the control unit of the basic machine

- MATIS - Hydraulic cutting unit: Hydraulic cutting units for cutting large diameter or high resistance winding materials e.g. underground cables