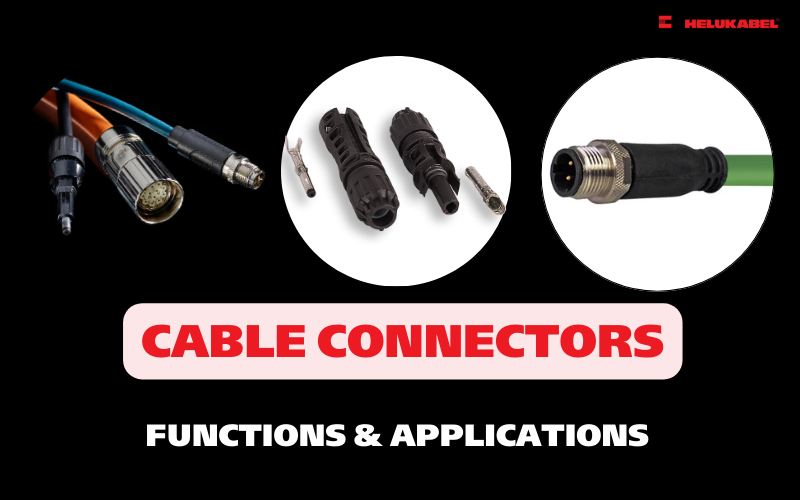

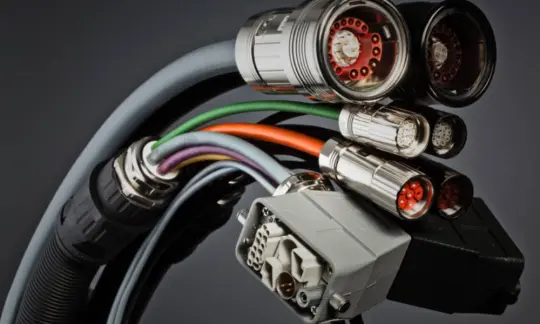

Classification of cable connectors – Common types of cable connectors

Based on termination ends, cable connectors are categorized into several types. Let’s explore the common types of cable connectors in the following article!

In the previous article, HELUKABEL provided basic information about the structure, function, and application of electrical cable connectors. In the next part of the article, let's explore the classification of cable connectors and some common types of connectors.

1. Types of cable connectors

Cable connectors are typically categorized into three main types based on their termination ends: board-to-board connectors, cable/wire-to-cable-/wire connectors and cable/wire-to-board connectors.

1.1 Board-to-board connectors

Board-to-board connectors are used to link printed circuit boards (PCBs) directly without requiring connecting cables, saving space and making them ideal for compact systems. These connectors allow PCBs to be connected in either parallel or perpendicular configurations, depending on the design requirements. A specialized type of board-to-board connector, known as the mezzanine connector, is used to stack two PCBs on top of each other, forming a stacking configuration.

1.2 Wire-to-wire connectors

Wire-to-wire connectors are designed to link two electrical cables. One end of the connector is permanently attached to the wire, while the other forms a separable interface. Permanent connections can be achieved using crimping techniques or Insulation Displacement Contact (IDC) technology. In IDC, a connection is created by inserting an insulated wire into a sharpened metal beam. The sharp edges of the metal cut through the insulation, establishing a robust metal-to-metal connection between the wire and the beam.

1.3 Wire-to-board connectors

Wire-to-board connectors serve to link a wire or cable to a printed circuit board (PCB). The wire connection process is similar to that used in wire-to-wire connectors, while board connections mainly involve two-piece connectors that are either soldered or pressed-in. Although card edge connectors are still in use, modern wire-to-board interfaces often resemble those in wire-to-wire connectors within the same product series, making them compatible and interchangeable.

While wire-to-board connectors have numerous applications, current trends are leaning toward cable-to-board connectors or cable assemblies. This shift allows for more extensive use of Insulation Displacement Contact (IDC) technology, providing efficient, robust, and space-saving connections by eliminating the need to strip insulation for installation.

2. Common connector styles

Based on the basic types of cable connectors, electrical cable connectors are generally categorized into different styles, with some common varieties including:

2.1 Circular connectors

Circular connectors are characterized by their cylindrical housing and round contact face. These electrical cable connectors are primarily used for connecting flexible cables, designed to be compact and space efficient. The contact points on the contact face may be arranged symmetrically, asymmetrically, in a circular layout, or in a straight line, and depending on the connector type, they may contain from one to 100 pins.

M8 and M12 circular connectors are widely used in factory automation, industrial machining centers, and production lines. These connectors are part of control systems for sensors, actuators, other I/O devices, and valve connectors. Depending on the application, these connectors are available in an A-coded version with various pole configurations. HELUKABEL offers circular connector products in two standard types: a metal version with shielding and a plastic version without shielding, equipped with a metal lock. All contacts are gold-plated and operate within a temperature range of -40°C to +85°C. Screw terminals are used for wire core connections (alternative options may be available).

2.2 Modular connectors

Modular connectors integrate similar or different contact systems within a common housing, typically assembled into modular units. These contact systems may include signal and power contacts, and some types even integrate optical fiber and/or pneumatic contact systems.

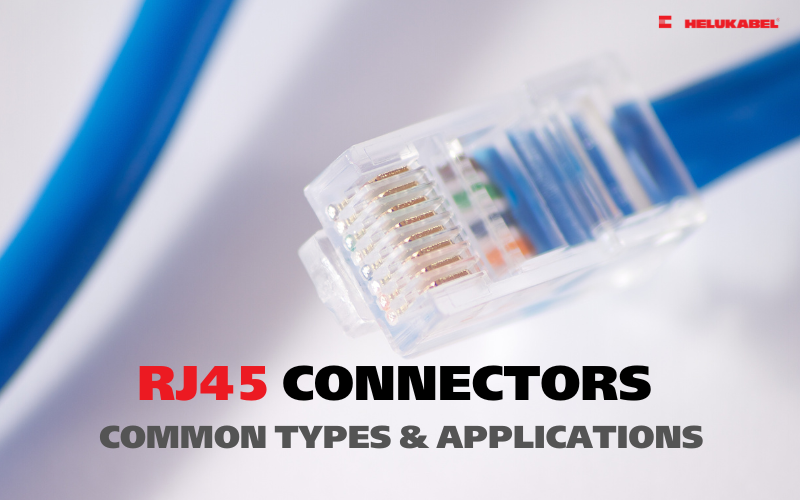

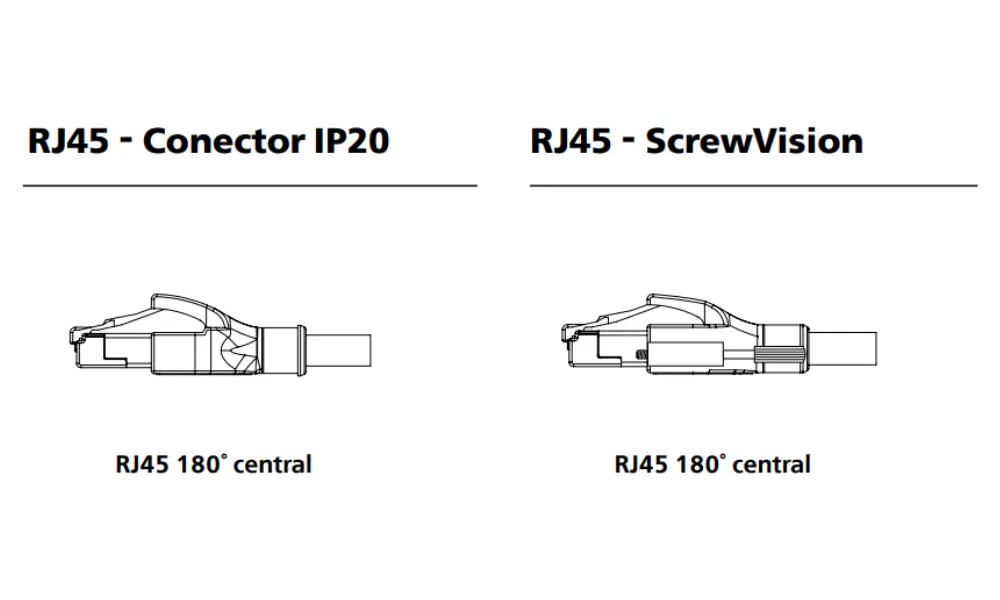

The use of modular connectors is a key driver behind the rapid expansion of global communication and data services. Among the most common types of modular equipment is the RJ45 connector. RJ45 cable connectors are mainly used to connect internet-enabled devices (such as computers) to other network devices like servers, routers, modems, smart TVs, gaming consoles, and other Ethernet-based devices. Ethernet networks are widely used in both industrial and residential settings. Hardwired connections via RJ45 equipment enable higher data transfer speeds, ensuring stability and security during transmission, making them an ideal choice for industrial sectors and factories as well.

RJ45 cable connectors from HELUKABEL come with several outstanding features, including:

- Versatile connection types: RJ45 connectors are available in various configurations, such as straight, 90°, 45°, 145°, and Push Pull types, suitable for diverse installation requirements.

- Flexible pin counts: The connectors come in 4-pin, 6-pin, and 8-pin options, accommodating a range of signal and data transmission applications.

- Compliance with PROFINET and TIA 568 A/B standards: RJ45 connectors are designed to meet these standards, ensuring uniform connectivity across industrial systems and data networks.

- High load capacity: HELUKABEL's RJ45 connectors support a wide range of cable core diameters, from small cables with a maximum core diameter of 1.6 mm to larger cables up to 8 mm.

- Water and dust resistance (IP67): Some connectors meet the IP67 protection standard, allowing for use in harsh industrial environments with high dust and water resistance requirements.

- Compatibility with different conductor types: HELUKABEL's RJ45 connectors support both solid and stranded conductors in various AWG levels, from 22 AWG to 24 AWG.

>>See more: What are RJ45 connectors?

2.3 DC MC4 connectors

MC4, short for "Multi-Contact, 4mm," is the standard connector in the renewable energy sector. Most large solar panels utilize DC MC4 cable connectors. This type features a round plastic housing with a single conductor in a male/female connector configuration, developed by Stäubli (formerly Multi-Contact), the official manufacturer of MC4 connectors.

The DC MC4 cable connectors are linked together using groove-locking devices, and in some cases, special tools are required to disconnect them. This locking mechanism prevents the cables from accidentally being pulled apart. Additionally, the DC MC4 connectors are weather-resistant, UV-resistant, and designed for long-term outdoor use.

HELUKABEL is the official supplier of Stäubli's DC MC4 connector products in the Vietnam market. Users can purchase the DC MC4-Evo 2A cable connector through our online store!

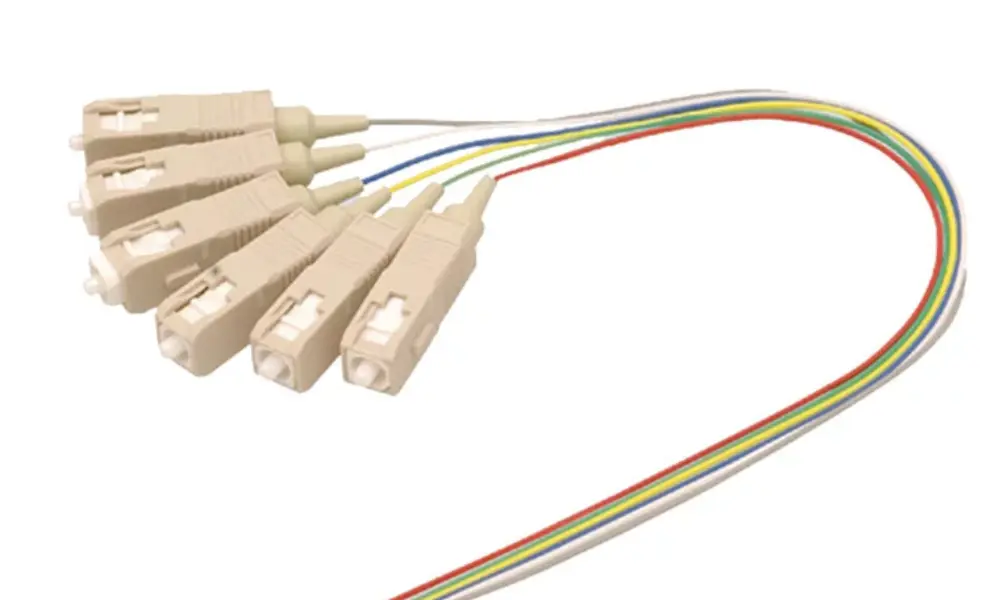

2.4 Fiber optic connectors

The transmission medium of optical connectors is made of glass or plastic fibers. These optical fibers must be aligned and connected with extreme precision (sub-micrometer level) to ensure the transmission of optical signals. This is achieved through positioning tubes (ferrules—high-precision guiding tubes) that can connect through round or rectangular connectors. This method allows for the connection of one to 100 optical fibers.

Advancements in technology and new applications have led to the development of various types of optical connectors (including LC, SC, F-SMA, MPO, MTRJ) and connection mechanisms (such as push-pull, twist, screw, and snap-lock).

HELUKABEL offers a wide range of optical connectors. These connectors are specially designed for industrial applications (both light and heavy duty) and are used with various types of fibers such as POF, HCS, and MultiMode. They can be assembled directly on-site and, depending on the type, are available in versions that are clamp, crimp, adhesive, or fusion spliced.

Additionally, HELUKABEL also provides optical fiber plugs and adapters, facilitating easy connections or disconnections for device outputs or distribution centers.

>>See more: What are fiber optic connectors - Solutions from HELUKABEL

2.5 Rectangle connectors

Rectangular cable connectors feature rectangular or trapezoidal contact surfaces, ensuring proper alignment when connecting. This type of connector is used to route flexible cables from the housing or components to the exterior. Rectangular connectors typically have an even contact arrangement, capable of transmitting electrical current from a few milliamps to hundreds of amps. They can also transmit data at speeds of up to gigabits. Depending on the size and transmission requirements, rectangular connectors can have up to 300 contact pins. These connectors can be integrated into modular systems, where different insert blocks, known as modules, are arranged within a rectangular housing to create a custom connector.

2.6 Coaxial connectors

Coaxial cables consist of an conductor surrounded by an insulating layer (dielectric) and an outer conductor (coaxial shield). Coaxial connectors are used to connect circuit boards, cables, and devices that transmit very high frequencies. Therefore, it is essential to maintain consistent impedance throughout the transmission system.

2.7 PCB connectors

PCB connectors are used to connect to contact points on printed circuit boards (PCBs). There are three main types of PCB connectors: wire-to-board connectors for connecting individual wires to the PCB, cable-to-board connectors for connecting round or flat cables to the PCB, and board-to-board connectors for connecting two PCBs together.

PCB connectors can be used for high-signal and high-current applications with fewer pins, or for communication technologies with more than 1,000 pins and data transfer rates exceeding 20 Gbit/s.

PCB connectors can be connected directly or indirectly to the circuit board. Indirect connection is a two-part contact method, where the connector is attached to a compatible contact part. Direct connection is a one-part solution, where the connector makes direct contact with the electrical pathways on the PCB without the need for a compatible contact part.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |