Installation, fire alarm cables and telecommunication cables for infrastructure and building

1. Installation cable

1.1 What are installation cables?

Installation cables are one of the most important components in modern electrical systems. This type of cable consists of multiple copper cores that are individually insulated and enclosed in a PVC or halogen-free polymer sheath. The outer sheath protects the conductors from mechanical impact and environmental factors.

1.2 Applications

Installation cables are used permanently in many environments: from apartments, offices, and factories to public works. Cables are usually embedded in walls, routed through protective conduits, or neatly placed on cable trays. There are also flat cables with parallel cores, suitable for embedding under plaster but only for use in dry areas.

Some important technical characteristics of installation cables are their fire resistance according to EN 13501 standards and mechanical strength. In particular, halogen-free sheathed cables are well suited for emergency escape routes due to their ability to limit the spread of fire and produce little smoke when burning.

1.3 Characteristics of installation cables

Today, electrical cables are not just for conducting electricity. Many types of cables can withstand temperatures up to 70 °C or higher. In particular, halogen-free sheathed cables are a safe choice because they do not emit toxic or corrosive gases when burned. Some specialized designs, such as installation cables with anti-static shielding for telecommunications, also ensure functional integrity—they continue to transmit electricity even in fire conditions.

2. Fire alarm cables

2.1 What are fire alarm cables

Fire alarm cables are control cables that connect the signal transmission line from the central system to the parts of the system including alarm lights, sirens, fire sprinkler systems, exit lights, automatic telephone dialers, etc. The specialized cable used for this system will ensure stable operation even in the event of a fire thanks to its fire resistance, and absolute limitation of fire spread. Even in the event of a fire, the cable can still transmit signals for a certain period of time.

2.2 Characteristics of fire alarm cables

Fire alarm cables have several outstanding features, including:

- Superior fire resistance: Fire alarm cables are designed to withstand high temperatures and continue to function effectively during a fire. They have excellent fire-resistant properties, preventing the spread of fire along the cable, which ensures that the fire alarm system remains operational to provide timely alerts.

- Durable construction: Fire alarm cables are typically insulated with high-quality materials like PVC or LSZH (Low Smoke Zero Halogen), which give the cables high durability and resistance to wear and tear. The outer sheath also offers protection against moisture, oil, and various chemicals, making it suitable for harsh environments. LSZH fire alarm cables, when exposed to fire, do not emit toxic smoke or halogen gases, reducing the risk of human poisoning and minimizing damage to sensitive electronic equipment.

- Stable signal transmission: Fire alarm cables provide stable signal transmission with high sensitivity, ensuring that fire alarm signals are transmitted quickly and accurately in emergency situations.

- High mechanical strength: Fire alarm cables have high mechanical strength, with good resistance to pulling and impact, ensuring reliable performance in large and complex construction projects.

2.3 Applications of fire alarm cables

Fire alarm cables can be used in various systems, ranging from basic fire alarm systems to more complex systems with addressable capabilities. They play a crucial role in protecting commercial buildings, connecting control panels, sensors, and fire alarms into a comprehensive system.

These systems operate on AC power, and fire alarm cables are designed to ensure that when one fire alarm is triggered, other alarms will also activate. The cables for fire alarm systems are available with or without shielding, allowing you to choose the appropriate type based on the level of electromagnetic interference (EMI) in the installation environment.

3. Telecommunications cables

3.1 The role of telecommunication cables in fire alarm systems

Fire alarm cables are used to transmit signals from fire alarm devices to the control center. Meanwhile, telecommunication cables are responsible for transmitting general data in communication systems. Fire alarm cables are fire-resistant, typically halogen-free and low-smoke, helping to limit toxic gases and thick smoke in the event of a fire. Functional integrity cables are particularly suitable for security systems such as fire alarm centers or sprinkler control systems.

3.2 Characteristics of telecommunications cables

- Maximum safety: Stable signal transmission even in extreme temperatures, protecting lives and property.

- Ensuring standards: The cable is CPR certified, fully meets legal requirements, and simplifies the approval process.

- Sustainable investment: Sturdy construction and premium materials reduce maintenance costs and minimize downtime.

- Versatile applications: Multiple options for indoor, outdoor, and underground installation, suitable for all projects.

Contact our HELUKABEL Vietnam engineers to get a quote & expert consultation

Find our products here:

1. Installation cables

Discover our products

2. Indoor telephone cables

Discover our products

3. Outdoor telephone cables

Discover our products

4. Switchboard cables

Discover our products

5. Fire alarm cables

Discover our products1. Installation cables

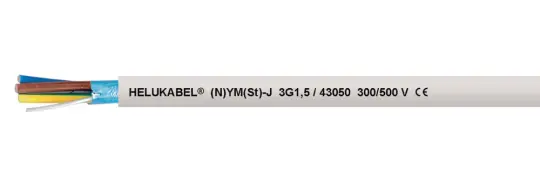

NYM installation cable is the most widely used type in building electrical networks.

It complies with the VDE standard (N), features PVC-insulated conductors (Y), and an overall PVC outer sheath (M) for reliable protection and durability.

| Cable name | Characteristics | Part number |

| YV-Equipment Wire 1 x 0.3 / 0.7 mm | YV – Equipment Cable: Single-core cable used in small equipment, switching systems, internal communications, and data transmission. Not for use in high-voltage installations. YR – Bell Cable with Sheath: For use in various applications with a maximum voltage of 100 V. | 28900 |

| NYM-J / NYM-O / (N)YM-J | For industrial and residential installations; suitable for dry, damp, or wet environments. Suitable for outdoor installation when protected from direct sunlight. | 39050 |

| NHXMH-J / NHXMH-O | Halogen-free installation cable with improved fire resistance properties. | 53300 |

| (N)YM(St)-J | Installation cable with static screen, designed for the effective limitation of electromagnetic interference fields | 43050 |

| NHMH-O / NHMH-J | Halogen-free cable, fixed installation, emission-free, 300/500 V. | 51970 / 51996 |

FAQs about installation cables

Advantages of VDE-certified installation cables

HELUKABEL tests and certifies all cables and conductors according to international standards such as VDE, ensuring consistently high safety and quality for a wide range of applications.

We combine in-house laboratory testing with assessments from independent inspection bodies like VDE. As a result, many of our products carry the official VDE certification number and are subject to regular audits throughout the entire production process in full compliance with this standard.

By strictly adhering to these requirements, HELUKABEL cables consistently meet both national and international certifications, providing safe and reliable performance in every installation.

Meaning of the NYM-J cable designation

NYM-J is the German standard designation for a PVC-insulated and sheathed installation cable. Each letter indicates a specific feature:

- N – Normleitung: Cable manufactured according to German/European standards.

- Y – PVC insulation for the individual conductors.

- M – Mantelleitung: Overall outer sheath made of PVC.

- J – Includes a green-yellow core that serves as the protective earth conductor.

Thanks to this construction, NYM-J cables are widely used in residential and industrial electrical installations, providing high safety and durability.

The meaning of conductor core colors in installation cables

The color of each conductor core indicates its specific electrical function.

According to European standard DIN VDE 0293-308, the meanings are:

- Brown and black – Phase (live) conductors: Carry current from the power source to the device.

- Blue – Neutral conductor: Returns current to the source and balances the circuit.

- Green-Yellow – Protective earth (Ground) conductor: Provides safety by directing any leakage current safely to earth.

This color-coding system is standardized across Europe to simplify installation, inspection, and maintenance of electrical systems.

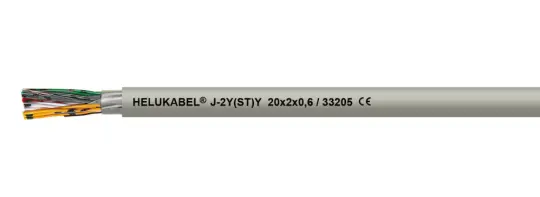

2. Indoor telephone cables

These are suitable cable models for installation inside the house, used for connecting signals in telephone stations, data transmission applications, and for peripheral device data processing computers. With high attenuation values, transmitting analog and digital signals up to 16 Mbit/s, the cable can be installed under gypsum board or fixed outside in areas without direct sunlight.

| Cable name | Characteristics | Part number |

| J-Y(St)Y Lg | PVC sheath, flame-retardant according to DIN VDE 0815 | 33001 |

| J-H(St)H Bd | FRNC sheath, flame-retardant, halogen-free according to DIN VDE 0815 standard | 34050 |

| J-2Y(St)Y St III Bd | 16 Mbits/s (Cat. 3) ISDN/EDV (Z = 100 Ohm) Special PE insulation Quad-type twisted insulating core | 33200 |

| J-YY Bd | Commonly used as telephone cables for exchanges and extensions, suitable for dry or damp environments, installed permanently inside or under plaster, as well as outdoors. | 33100 |

| J-2Y(St)H St III Bd | 16 Mbits/s (Cat.3) ISDN/EDV (Z = 100 Ohm), halogen-free | 34166 |

3. Outdoor telephone cables

This is a telecommunications cable suitable for outdoor installation that connects telephone systems to the central office of each network. The cable is installed inside cable conduits and underground, with a cable sheath made of PE material that is waterproof, moisture-resistant, and effectively UV-resistant. The cable contains no halogens.

| Cable name | Characteristics | Part number |

| A-2Y(L)2Y |

| 34100 |

| A-2YF(L)2Y |

| 34007 |

4. Switchboard cables

These are preferred for the transmission of data signals of telecommunication and control processings i. e. in interlocking installations, to connect the outdoor cables with relay groups as well as for fixed installation to interconnect the racks and distributor frames. This type is not allowed for the installation of heavy current operation.

5. Fire alarm cables

These are specialized cables used in fire alarm systems. This type of cable is equipped with a static electricity shielding (St) to protect the entire signal transmission circuit from external electrical interference. The cable is suitable for installation in both dry and humid environments, inside or underneath gypsum layers, or fixed outdoor installations. The cable is completely halogen-free with fire-resistant and anti-flame outer casing material.

| Cable | Properties | Approval | Part no. |

| J-H(St)H | Bd fire warning installation cable, halogen-free | UKCA | 34116 |

| JE-H(St)H | Bd FE 180/E 30 up to E 90 (orange), halogen-free | UKCA | 34081 |

| JE-H(St)H | Bd fire warning cable, FE 180/E 30 to E 90 (red), halogen-free | UKCA | 34091 |

| JE-H(St)H | Bd fire warning cable, FE 180/E 30 to E 90 (red), halogen-free | UKCA | 34157 |

FAQs about fire alarm cables

Common causes of electrical cable fires

Electrical cable fires can result from several factors:

- Overcurrent/overload: Excessive current causes the conductor to overheat.

- Short circuits: Arcing and high temperatures ignite nearby materials.

- Poor or loose connections: Increased resistance at joints generates dangerous heat.

- External heat sources: Industrial equipment or nearby fires can raise cable temperatures.

When the insulation overheats and ignites, flames can quickly travel along the cable length. Selecting fire-resistant materials and properly sizing conductors are therefore critical to ensure the safety and reliability of any electrical installation.

Key features of HELUKABEL fire-alarm cables

- Halogen-free: Emit no toxic or corrosive gases during a fire, ensuring safety for people and equipment.

- Functional integrity: Maintain reliable signal transmission even under fire conditions.

- Underground installation: Robust construction resists mechanical stress and moisture, suitable for direct burial.

- Outdoor use: Weather-resistant for dependable performance in exposed environments.

- Indoor use: Optimized design for safe, long-term installation in buildings and infrastructure.

These qualities enable HELUKABEL fire-alarm cables to meet stringent safety standards while delivering exceptional durability for every project.

Halogen-free fire alarm cables – Dual protection against flames and toxic fumes

Fire alarm cables must both prevent flame propagation and avoid releasing hazardous gases in the event of a fire. Traditional halogen-based materials such as PVC or PTFE can slow down flame spread but emit corrosive and toxic fumes when burning.

To overcome this, HELUKABEL uses aluminium hydroxide in its halogen-free fire alarm and telecommunication cables. When exposed to high temperatures, aluminium hydroxide decomposes endothermically, releasing water vapour that cools the cable surface and reduces the oxygen level - effectively suppressing the fire.

This reaction generates no acidic gases and produces minimal, low-toxicity smoke compared with halogen-containing cables. Notably, certain models such as FE(EI)180/E30 can maintain full functionality for up to three hours, ensuring that critical systems continue operating safely during an emergency.

Distinguishing Insulation Integrity (FE/EI) vs. Functional Integrity (E)

- Insulation Integrity – FE/EI: Tests only the cable itself. Under fire conditions, the insulation must remain intact so that no short circuit occurs between conductors or to ground. This standard focuses on the quality and fire-resistance of the insulating material.

- Functional Integrity – E: Evaluates the entire system, including cables, supports, accessories, and installation method. It measures whether the complete fire-alarm or fire-fighting circuit continues to operate during a fire. In modern building design, the E certification is considered more critical and practical because it guarantees that essential systems—such as fire detection or suppression—remain operational in real fire scenarios.

Meaning of the FE(EI)180/E30 marking for fire-alarm cables

- FE(EI)180: The cable’s insulation can withstand direct fire for at least 180 minutes without any conductor-to-conductor or conductor-to-ground short circuit.

- E30: In addition to insulation integrity, the entire system - including the cable, supporting hardware, and installation method - remains fully functional for at least 30 minutes during a fire.

For critical facilities such as hospitals, data centers, or industrial plants, choosing cables certified to FE(EI)180/E30 ensures both personal safety and reliable operation of fire-alarm and fire-suppression systems long enough to enable safe evacuation and emergency response.

Does a fire alarm cable have to be halogen-free?

Not strictly, but reputable manufacturers such as HELUKABEL strongly recommend using halogen-free fire alarm cables.

Benefits of halogen-free cables:

- Low smoke, no corrosive gases: In a fire, they do not release toxic or corrosive fumes, which helps protect sensitive electronic equipment and safeguards human health.

- Compliance: Halogen-free cables often meet the European CPR (Construction Products Regulation) standards, streamlining project approvals and enhancing overall building safety.

While halogen content is not legally mandatory in every application, halogen-free fire alarm cables provide a higher level of safety and reliability for modern installations.

Why are fire-alarm cables often red?

Fire alarm cables are not required by international standards to be red. There is no global regulation mandating a specific jacket color.

- Purpose of red color: Red is simply a visual identifier that allows installers, inspectors, and maintenance teams to quickly distinguish fire alarm cables from other wiring types.

- Key selection criteria: When choosing fire alarm cables, the technical properties, fire-resistance ratings, and safety certifications are far more important than the outer color of the sheath.