2 Key criteria for choosing insulating sheaths for cables

Along with external factors, insulating sheath is an internal one that affects the durability of electric cables. Based on the cable structure, there are two important criteria for choosing the sheaths.

1. Insulating materials for electric cable sheath

In the cable, the insulating sheath serves as the element directly in touch with the wire core, protecting the core and preventing short circuits inside the cable. The cables with suitable insulating sheaths guarantee the uninterrupted operation of machines and minimize downtime.

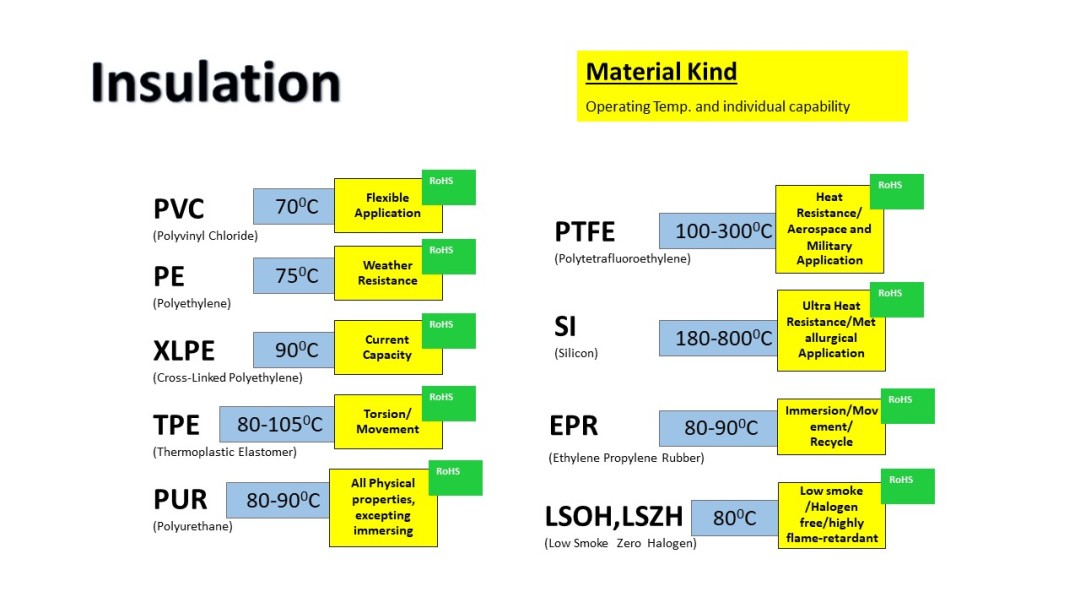

The typical materials used for insulating sheaths include:

· PVC (Polyvinyl Chloride)

· PE (Polyethylene)

· XLPE (Cross-linked Polyethylene)

· PUR (Polyurethane)

· Silicon (SI)

Each type of material has its own characteristics tailored for specific applications.

1.1. PVC (Polyvinyl Chloride)

PVC is a popular choice for insulating sheaths thanks to its versatility, affordability, chemical resistance and heat resistance up to 70°C. The cables with PVC insulating sheaths are often used in home wiring and low-voltage applications.

1.2. PE (Polyethylene)

PE is a material that can endure extreme weather conditions and withstand temperatures ranging from more than 70°C down to -40°C. Therefore, it is often used in outdoor applications such as fiber optic cables or network cables.

1.3. XLPE (Cross-linked Polyethylene)

XLPE has all the properties of PE with the ability to withstand high temperatures up to 90°C, along with relatively high dielectric strength. Therefore, cables with XLPE insulating sheaths are often used in high-voltage environments.

1.4. PUR (Polyurethane)

This material encompasses nearly all the essential properties required for a cable, from good elasticity that promotes flexibility to resistance against oil/chemicals and abrasion. These qualities render cables with PUR insulating sheaths highly suitable for machinery or product processing applications. However, a drawback of PUR is its inability to withstand liquid-submerged environments.

1.5. Silicon (SI)

Cables with SI insulating sheaths are commonly used in high-temperature environments such as iron, steel or aerospace industries. This is because SI demonstrates the ability to withstand high temperatures up to 800°C.

1.6. Other materials

Apart from the mentioned materials, other materials utilized in fabricating insulating sheaths for cables are TPE, PTFE, EPR, LSOH, LSZH, etc. Each of these materials has distinct features designed for particular applications.

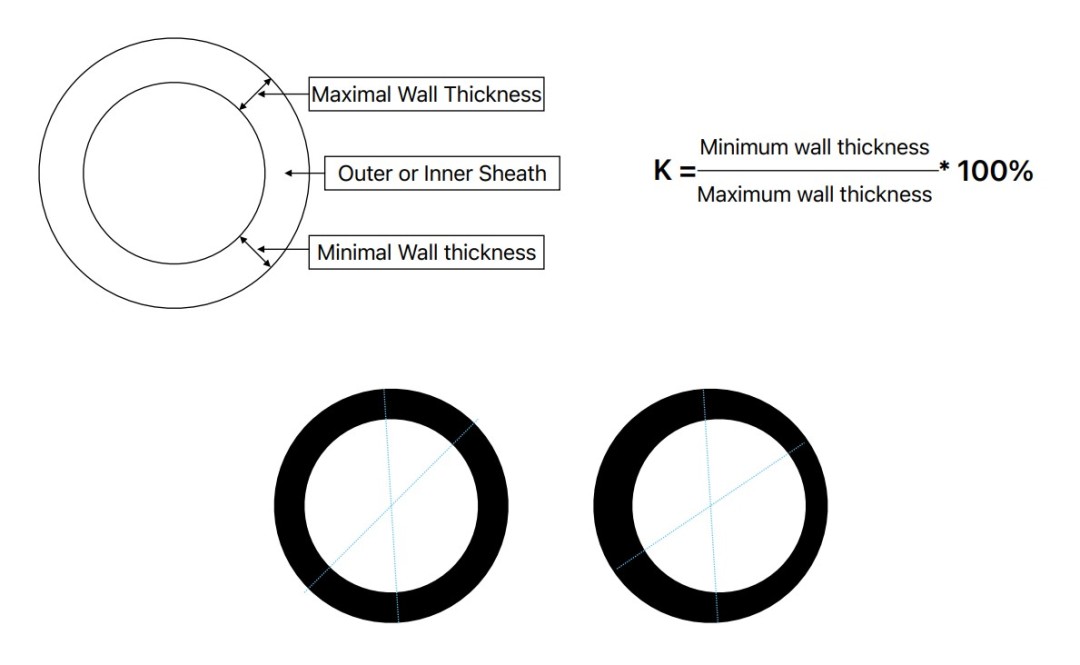

2. Thickness of insulating sheaths of electric cables

"Concentricity" is a common term in discussing the thickness of insulating sheaths. Optimal concentricity in a shell denotes uniform thickness. Any lack of concentricity in the insulation layer elevates the risk of abrasions while pulling the cable through connections, bends, or redirections in ladders and cable trays. This, in turn, could lead to electrical leakage or short circuits.

HELUKABEL's cables are manufactured with advanced technology and equipment, and meticulous microscopic inspections ensure stringent quality control. Therefore, the cables consistently meet standard concentricity requirements - typically around 80%.

For detailed guidance on HELUKABEL’s cables, schedule a consultation appointment with our engineer here or reach out to us at:

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn