TÜV, UL, CSA, IEC, EN: Decoding the standards for DC cables

The growing demand for renewable energy sources has driven the widespread use of solar DC cables worldwide. However, their quality and safety can vary depending on the manufacturer. To ensure that solar cables meet the required standards for performance, safety, and reliability, testing and certification are essential.

1. The diverse operating environments of DC cables

The operating environments of DC cables are extremely diverse, posing significant challenges to the quality and performance of DC cables. Each specific environment requires DC cables to meet distinct standards.

1.1 Solar power systems in extremely harsh temperature conditions

Under the intense heat generated by solar energy, DC cables face several challenges, such as:

- Cable sheath discoloration, fading, or even damage, compromising the protective function of the outer jacket.

- The appearance of cracks or surface fractures on the cable.

- Beyond visible effects, high temperatures can also threaten the operation and overall safety of the entire system, leading to risks such as fire or explosion, reduced mechanical strength, and shorter cable lifespan.

Floating PV projects are becoming increasingly popular

1.2 The rise of floating PV projects

As available land for solar power installations becomes increasingly scarce and the pressure to reduce carbon emissions grows, utilizing water surfaces such as reservoirs, artificial lakes, and even coastal areas has emerged as a highly promising solution. This approach is particularly advantageous for countries with abundant water surfaces and long coastlines, such as Vietnam.

However, great potential comes with significant challenges. In these projects, DC cables must withstand:

- Water intrusion that can damage connection points. In addition, offshore solar power systems face high humidity, saltwater corrosion, and mechanical stress caused by waves.

- Power loss due to the long transmission distance between the solar panels and the energy storage units.

Rodents pose a challenge to DC cables installed in tropical climates and solar-integrated agricultural settings

1.3 Rodent challenges in solar power projects

When discussing solar power projects, resistance to environmental temperature is often the first factor considered. However, in tropical climates, outdoor installations, or agrivoltaics systems (where agriculture is combined with solar energy production), DC cables also face threats from rodents and other animals. Common issues include:

- Rats gnawing on the cable sheath, exposing the conductive core and causing dangerous short circuits or electrical faults.

- Termites and ants damaging the insulation layer, especially in humid or tropical regions where insect density is high.

- Snakes and small insects entering cable conduits to access inverter rooms or junction boxes, posing safety hazards and potential equipment damage.

1.4 Market challenges

One of the greatest challenges for manufacturers and suppliers of solar cables lies in the differences in technical standards and certifications across global markets.

Each region or country has its own set of standards for evaluating the quality, safety, and performance of PV cables. For example, UL in North America, TÜV Rheinland/VDE widely applied in Europe, and IEC on an international scale.

2. The role of certifications and approvals for DC cables

Given the wide variety of installation environments for solar DC cables, the need for unified, industry-recognized standards has become increasingly essential. Without such standards, the processes of system design, installation, and testing would become more complex — especially for large-scale international projects.

Therefore, the solar energy industry requires a unified set of international standards that are recognized by global certification bodies. These standardized regulations help to:

- Simplify product testing and certification across markets: Certification ensures that DC cables are manufactured and tested according to defined quality standards. As a result, certified products are less likely to experience early failures and are more likely to deliver the expected power output as guaranteed by the manufacturer.

- Ensure compatibility and safety during installation, particularly when system components are sourced from multiple suppliers.

- Enhance the reliability, lifespan, and operational efficiency of the entire solar power system. Since DC cables can carry high voltages, improper installation or damage can pose serious risks such as electric shock or fire. Certification ensures that products have been thoroughly tested and comply with stringent safety standards.

3. Common standards for DC cables in photovoltaic systems

3.1 TÜV Rheinland 2 PfG 2750 standard

TÜV 2PfG 2750 is a German quality standard developed by TÜV Rheinland, one of the world’s leading testing and certification organizations. This standard specifies the requirements for DC cables with enhanced water resistance, designed to meet the specific demands of floating solar power systems. Today, TÜV 2PfG 2750 is widely recognized worldwide and serves as a reliable benchmark for solar cable quality.

However, for DC cables certified under the TÜV 2PfG 2750 standard, it is important for users to distinguish between AD7 and AD8 protection levels. According to TÜV’s definition, cables certified to TÜV 2PfG 2750 are not officially certified to AD8. The standard only covers AD7-rated applications with enhanced water resistance. Therefore, any product claiming to be AD8-compliant under TÜV 2PfG 2750 is making an independent declaration, which has not been officially recognized by TÜV.

3.2 IEC 62930 standard

Common IEC standards for DC cables used in solar power systems include IEC 62930, IEC 60216, and IEC 60502. Some of the key requirements for DC cables as defined by IEC 62930 are as follows:

- Maximum operating temperature: 90°C

- Permissible operating temperature of conductor: 120°C

- Rated voltage: 1.5 kV

- Conductors should be made of copper and comply with IEC 60228

- The insulation and sheath materials should be cross-linked compounds, and the outer sheath is typically required to be black

3.3 UL 4703 standard for solar cables

With the global shift toward renewable energy, the photovoltaic industry is expanding at an unprecedented pace. The DC voltage levels in solar power plants have continuously increased - from 600 V in the early stages to 1000 V, 1500 V, and now 2000 V, marking a new trend in high-efficiency solar power systems.

To meet these stringent requirements, UL 4703 PV cables have become the preferred choice in the American market. Certified for DC voltages of up to 2000 V, UL 4703-compliant DC cables are considered an ideal solution for high-voltage solar power installations.

3.4 CSA-Std. C22.2 No. 271

The CSA C22.2 No. 271 certification is an important standard for DC cables in Canada.

Issued by the Canadian Standards Association (CSA), this certification focuses on cables specifically designed for solar power systems in both residential and commercial applications.

Cables that meet the CSA C22.2 No. 271 standard must ensure safe and stable power transmission from solar panels to the inverter, power grid, or energy storage systems, even under the harsh environmental conditions typical of Canada’s climate.

DC cable products must pass tests to ensure superior characteristics in harsh operating environments.

3.5 EN 50618 standard

EN 50618 is the European standard that defines the technical requirements for cables used in PV systems, particularly DC cables.

The designation DIN EN 50618 refers to the German version of the EN 50618 standard. This version, published by the German Institute for Standardization (DIN – Deutsches Institut für Normung), is identical to EN 50618, differing only in publication system and numbering format.

Key requirements for DC cables as specified in EN 50618 include:

- The insulation and sheath must be made of cross-linked materials.

- The rated DC voltage is 1.5 kV between conductors or between a conductor and ground.

- The cable is designed for continuous operation at a maximum conductor temperature of 90°C, with short-term operation (up to 20,000 hours) allowed at higher levels.

- The conductor temperature may reach 120°C when the ambient temperature is up to 90°C.

- The expected service life of the cable, under normal operating conditions as defined by the standard, is at least 25 years.

- DC cables compliant with EN 50618 must pass rigorous tests to ensure superior performance in demanding environments. These include: Flame retardancy (vertical flame test according to EN 60332-1-2), smoke density testing (in accordance with EN 61034-1+2), UV and weather resistance testing (as specified in Annex E of EN 50618)

4. Comparison between different standards for DC cables

4.1 Overview of key standards

| Standard | Scope | Outstanding features |

| TÜV Rheinland 2 PfG 2750 | German standards, increasingly recognized worldwide | Specifies requirements for DC cables with enhanced water resistance, suitable for floating PV |

| IEC 62930 | Global | Widely accepted international standard for DC cables |

| UL 4703 | North America | DC voltage up to 2000V, ideal for high-voltage solar power projects |

| CSA Standard C22.2 No. 271 | Canada | Similar to UL standards |

| EN 50618 | European standards | Part of the European harmonized standards system; compliance is often required for CE marking, indicating that the product meets European requirements for safety, health, and environmental protection |

Unlike other standards, UL 4703 permits aluminum as the conductor material for DC cables

4.2 Key considerations for DC cable standards

Although all DC cable standards aim to ensure safety and durability, each standard has specific differences. When selecting DC cables, the following technical factors should be carefully considered:

- Temperature range: Most standards specify the same operating range, from -40°C to +90°C.

- Conductor material: For IEC 62930 and EN 50618, conductors are typically made of copper, class 5 according to IEC 60228. A notable difference in UL 4703 is the acceptance of aluminum conductors, offering a more economical option. UL 4703 also allows larger conductor sizes, up to 12 AWG (2,000 kcmil aluminum), suitable for large-scale solar projects.

- Rated voltage: Usually 1500 V, except for UL, which allows 2000 V. The increase to 2000 V represents a significant shift in solar power systems, enabling higher power transmission.

- Flame test: Most standards use vertical flame testing according to IEC 60332-1+2. For UL/CSA, products are tested for flame propagation resistance using UL VW-1 or CSA FT-1. The UL VW-1 test is similar in principle to IEC 60332-1, but differs in longer flame exposure times and stricter test cycles.

5. HELUKABEL’s DC cable portfolio for photovoltaic systems

HELUKABEL’s DC cable portfolio is manufactured according to widely recognized industry standards:

| Our products | DIN EN 50618 standard | IEC 62930 standard | UL 4703 Standard | Other standards |

| SOLARFLEX®-X H1Z2Z2-K |

| |||

| SOLARFLEX®-X H1Z2Z2-K NTS |

| |||

| HELUPOWER® SOLARFLEX®-X H1Z2Z2-K UL |

|

|

| |

| HELUPOWER® SOLARFLEX®-X PREMIUM |

|

| TÜV Rheinland 2 PfG 2750 | |

| HELUPOWER® SOLARFLEX®-X RPVU90-AL |

| CSA Standard C22.2 No. 271 | ||

| HELUPOWER® SOLARFLEX®-X RPVU90-CU |

| CSA Standard C22.2 No. 271 |

The DC cables in our product portfolio share the following common features:

- Operating temperature range: -40°C to +90°C

- Maximum conductor temperature: +120°C

- Rated voltage: 1500 V (DC)

- Halogen-free and flame-retardant

- Resistance to UV radiation, ozone, and weathering

By meeting various standards, our solar power cables are suitable for a wide range of environments. Each product is designed with enhanced characteristics tailored to specific applications, as detailed below:

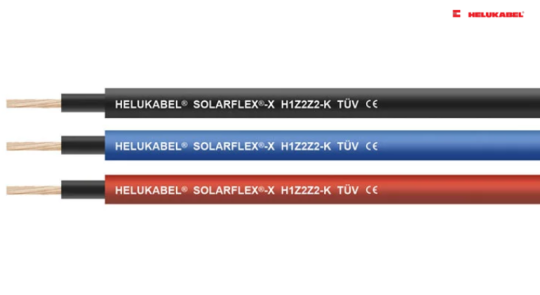

5.1 SOLARFLEX®-X H1Z2Z2-K cable – Standard design for solar projects

- This is a standard version DC cable for solar power projects, manufactured according to DIN VDE 0283-618 / DIN EN 50618 standards.

- Cross-sectional area range from 2.5 to 240 mm²

- Comprising three different colors, each color meets a specific technical requirement in the solar power system: red, black, and blue.

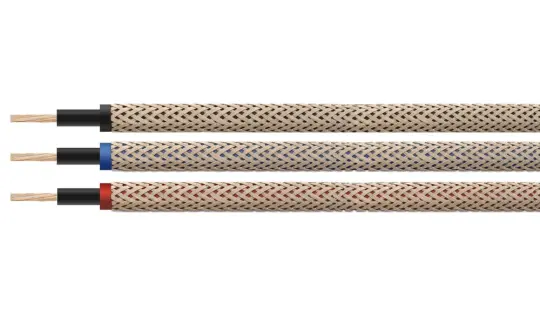

5.2 SOLARFLEX®-X H1Z2Z2-K NTS – Chemical-free rodent protection solution

Compared to the standard design, the NTS version of our DC cable features an additional V2A stainless steel braid, which enhances the mechanical protection of the cable. This makes it an effective solution to prevent damage from rats, martens, or other rodents, ensuring uninterrupted operation of solar power systems in environments such as:

- Underground solar installations

- Agrivoltaic (solar-agriculture) systems

- Tropical climates, where rodent activity is high

This product is also available in three colors (red, black, blue) and the three most common cross-sections for solar projects: 4 mm², 6 mm², and 10 mm².

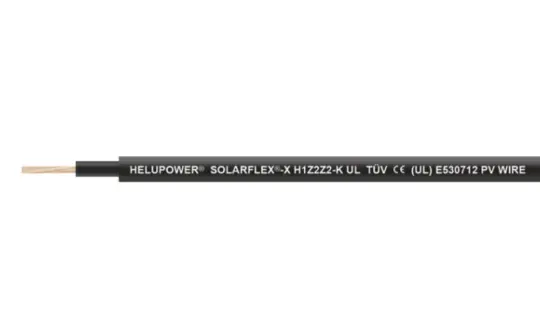

5.3 HELUPOWER® SOLARFLEX®-X H1Z2Z2-K UL – UL-certified version

This solar DC cable is designed to meet both U.S. market standards (UL 4703) and widely recognized international standards (IEC 62930, DIN EN 50618).

Key features of this cable include:

- Rated voltage up to 2000 V (UL)

- Enhanced UV resistance (SUN RES) according to UL Std. 1581 Sec. 1200

- Black outer sheath, available in three common cross-sections: 4 mm², 6 mm², and 10 mm²

HELUPOWER® SOLARFLEX®-X PREMIUM DC cable has enhanced water resistance according to TÜV Rheinland standard 2 PfG 2750.

5.4 HELUPOWER® SOLARFLEX®-X PREMIUM – Solution for floating PV

This cable features enhanced water resistance in accordance with TÜV Rheinland 2 PfG 2750. Combined with the superior properties of cross-linked materials and strong environmental durability, HELUPOWER® SOLARFLEX®-X PREMIUM DC cables provide an optimal solution for floating solar power installations. These cables can be installed in freshwater up to 1 meter deep.

The product is available in two colors: red and black, covering both common cross-sections and larger conductor sizes. Cables with larger cross-sections (50 mm², 95 mm² … up to 240 mm²) are particularly suitable for long-distance power transmission or large-scale solar farms.

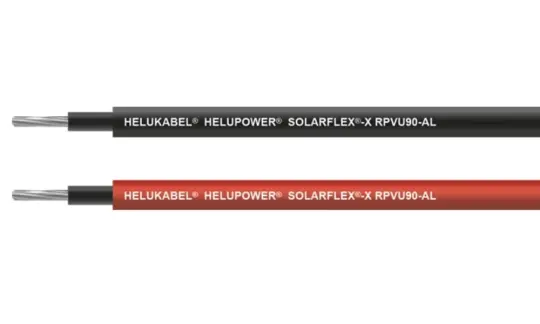

5.5 HELUPOWER® SOLARFLEX®-X RPVU90-AL – Aluminum DC cable

This is a special version in HELUKABEL’s DC cable portfolio, featuring an aluminum conductor instead of copper. Using aluminum reduces weight and material costs while still providing excellent electrical conductivity when properly sized. Combined with advanced insulation, this cable is designed to efficiently transmit high DC voltages and large currents over long distances.

With a rated voltage (UL) of up to 2000 V DC and large conductor cross-sections ranging from 350 kcmil to 1500 kcmil (approximately 185–760 mm²), this cable is ideal for large-scale solar power systems and energy storage systems.

5.6 HELUPOWER® SOLARFLEX®-X RPVU90-CU

This cable has a rated voltage (UL) of up to 2000 V, suitable for applications requiring high performance and long-term reliability.

Key features include:

- Two colors: red and black, for easy polarity identification

- Four conductor cross-section options: 8, 10, 12, and 14 AWG

- High-quality copper conductors and cross-linked insulation ensure excellent conductivity, minimize voltage drop, and provide stable long-term operation in outdoor environments

If you still have questions, don't forget to contact HELUKABEL Vietnam's team of engineers for detailed answers.

HELUKABEL® Vietnam

| Address | 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000 |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover and purchase our products on | Tiki | Shopee | Lazada | Product finder |

| Connect with us on | Facebook | LinkedIn | Instagram | YouTube | Zalo | WhatsApp | TikTok | Spotify |