Drag chain cable BIOFLEX: bio-oil and bacterial resistant

Depending on different environmental conditions, you can use other cables. The selection of cable lines maximizes the cable's features and ensures the project's productivity at the most optimal level.

1. Bacterial and bio-oil-resistant drag chain cable

Bacterial and bio-oil resistant cable is a series of drag chain cables, biofuel resistant, wear-resistant, eco-friendly recyclable, bio-oil resistant, and rated meter mark. Specifically, this line of control cables has the following characteristics:

- Resistant to biofuels (engine oil and gasoline), especially highly resistant to biodegradable oils, oxygen, ozone, hydrolysis, and bacteria

- Low adhesion

2. BIOFLEX-500®-JZ-HF drag chain cables

2.1 Cable structure

- Bare copper, extra fine wire conductors, bunch stranded to DIN VDE 0295 cl.6, BS 6360 cl.6 and IEC 60228 cl.6

- Core insulation of special polymer with the improved sliding ability

- Core identification to DIN VDE 0293 black cores with continuous white numbering

- GN-YE conductor, 3 cores and above in the outer layer

- Cores stranded in layers with optimally selected lay-length

- Wrapping with fleece

- Outer sheath of the special polymer compound

- The sheath colour is dark green

- with meter marking

2.2 Technical data of BIOFLEX-500®-JZ-HF drag chain cable

- Bio-oil resistant, abrasion resistant special high flexible control cable adapted to DIN VDE 0285-525-1/DIN EN 50525-1

- Temperature range:

flexing -20°C to +80°C

fixed installation -40°C to +80°C

- Nominal voltage U0/U 300/500 V

- Test voltage 3000 V

- Insulation resistance min. 20 MOhm x km

- Minimum bending radius

flexing 10x cable Ø

fixed installation 4x cable Ø

- Radiation resistance up to 100x106 cJ/kg (up to 100 Mrad)

2.3 Application of drag chain cable BIOFLEX-500®-JZ-HF

HELUKABEL® BIOFLEX-500®-JZ-HF is an extremely strong and highly flexible control drag chain cable with good abrasion and tear resistance. Due to its resistance to biofuels, bio-oils, and coolants, this cable is particularly suitable for use in machinery, tool, plant, and steel industries with harsh environments. In addition, it is also suitable for combination with cable trays in dry, wet rooms and outdoor installations. The high flexibility of this cable makes installation quick and easy.

For large-scale or mission-critical applications, we recommend expert advice and guidance. For applications beyond standard solutions, it is recommended that you use our specially developed requirements table for energy conductive systems. Before installing the cable tray, please read the instructions and other specifications carefully. The product is conformed with the EC Low-Voltage Directive 2006/95/EC

3. BIOFLEX-500®-JZ-HF-C drag chain cables

3.1 Drag chian cable structure

- Bare copper, extra fine wire conductors, bunch stranded to DIN VDE 0295 cl.6, BS 6360 cl.6 and IEC 60228 cl.6

- Core insulation of special polymer with the improved sliding ability

- Core identification to DIN VDE 0293 black cores with continuous white numbering

- GN-YE conductor, 3 cores and above in the outer layer

- Cores stranded in layers with optimally selected lay-length

- Wrapping with fleece

- Special inner sheath

- Copper braided screening approx. 85% coverage

- Wrapping with fleece guarantees a good dismantling

- Outer sheath of the special polymer compound

- The sheath colour is dark green

- with meter marking

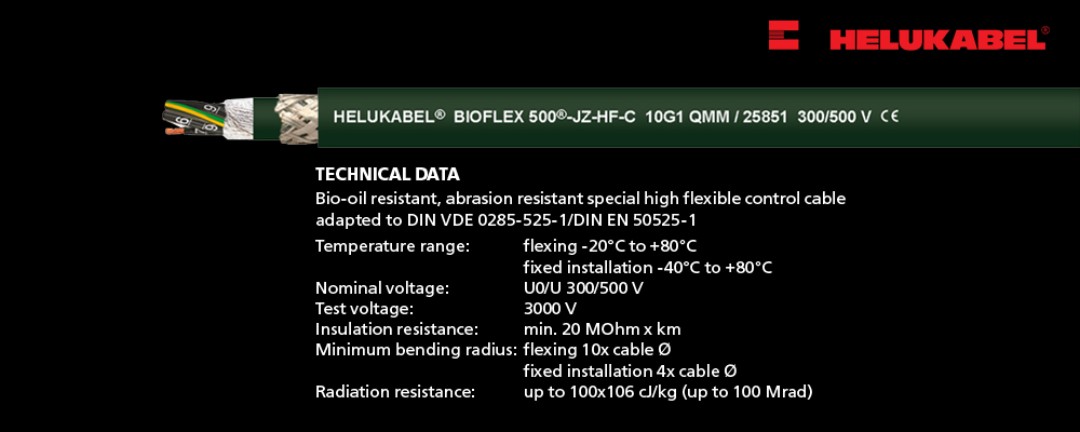

3.2 Technical data

- Bio-oil resistant, abrasion resistant special high flexible control cable adapted to DIN VDE 0285-525-1 / DIN EN 50525-1

- Temperature range

flexing -20°C to +80°C

fixed installation -40°C to +80°C

- Nominal voltage U0/U 300/500 V

- Test voltage 3000 V

- Insulation resistance min. 20 MOhm x km

- Minimum bending radius

flexing 15x cable Ø

fixed installation 4x cable Ø

- Coupling resistance max. 250 Ohm/km

- Radiation resistance up to 100x106 cJ/kg (up to 100 Mrad)

3.3 Application of this drag chain cable

HELUKABEL® BIOFLEX-500®-JZ-HF-C is an extremely robust and highly flexible control drag chain cable with high abrasion and tear-resistant properties. Due to its high resistance to Biofuel, Bio-oil, and coolant emulsions. It is especially suited for use in the machine, tool making, and plant industries as well as in the steel industry for difficult and problem areas. Suitable in combination with cable trays in dry, moist, and wet rooms and outdoor installation. The high flexibility of this cable type makes it quick and easy to install. Suitable for outdoor lying. These screened cables are particularly suitable for interference-free transmission in instrumentation and control engineering applications (electromagnetic compatibility).

For critical applications, we advise consultation. For applications that go beyond standard solutions (for example composting appliances or high-shelf conveyors with extremely high processing speeds etc.) we recommend our specially developed inquiry sheet for energy guiding systems. Before installation in cable trays please read the instructions. For further technical details see the selection table for drag chain cables, see lead text. To optimize the EMC features we recommend a large round contact of the copper braiding on both ends. The product is conformed with the EC Low-Voltage Directive 2006/95/EC.

HELUKABEL is one of the oldest manufacturers and suppliers of cables and accessories with more than 40 years of experience. We have experts, experienced engineers, and product manufacturing processes that comply with international standards, thus any specific cable specifications can be met quickly thanks to our customized solutions. Please contact our engineers if you need advice or answer related to technical problems.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn

OTHER POSTS >>> ALWAYS STABLE OPERATION