Why should F&B factories invest more in cables?

With the characteristics of the F&B industry, the selection of control cables needs to meet the criteria of water resistance, oil resistance, chemical resistance, and the use of stainless steel. The F&B industry requires the use of electrical cables that meet strict hygiene standards, absolutely not allowing bacteria and impurities to come into contact with the output product.

Food and Beverage Service (F&B) is a service business model to produce and trade food and drinks. Factories operating in the F&B sector require maximum hygiene standards. In addition, the production space is often humid, and the temperature is very high or very low, especially in some locations in the factory, there are cleaning chemicals and oils, etc. Therefore, the equipment and the control cable system are subject to strong corrosive effects of various substances, which requires the cable to be able to withstand the above factors, prevent the risk of bacterial growth, and affect product quality.

1. Requirements of cables used in the F&B industry

Given the characteristics of factories and shops operating in the F&B industry, we can partly understand that the selected control cable must meet certain minimum standards.

- The cable is resistant to harsh detergents

- The ability to withstand extreme temperatures does not expand upon sudden temperature change

- The cable is waterproof and completely halogen-free

- The type of steel used in the cable is stainless steel, with high durability

- The cable cover ensures no corrosion by chemicals, biological oils, or grease.

- The cables used must be able to withstand chemical and mechanical stress, and certified to FDA, and ECOLAB standards.

The above requirements are to ensure that after some time, the quality of the cable is not affected and causes negative impacts on the products that the factory produces. At the same time, the cable must not be changed in terms of the nature and structure of the inner core and outer sheath, in case the cable is exposed, causing danger to plant personnel.

2. Why do factories in the F&B industry need to invest in power cables?

The selection of high-class power cables suitable for the production characteristics of the industry in recent years has been increasingly focused on. When deciding to invest in replacing power cables, it will bring the following benefits:

2.1 Ensure hygiene standards

Use cables used when meeting extreme temperature conditions, using stainless steel materials, not corroded by chemicals. The cable will ensure that the surface of the cable sheath is always clean and dry. This minimizes the growth of mold and bacteria. At the same time, reducing the risk of affecting the product quality of the factory.

2.2 Increased safety for the production environment

When choosing a cable that can withstand the impact of many types of detergents for a long time, using a stainless steel core, and meeting FDA or ECOLAB standards, the product will ensure the safety of employees and workers in the production area. In case of using poor quality cables, the sheath will be corroded and cause open and broken sections which are dangerous to workers. Not only that, the openings or faults can also affect the production and processing of food and beverages, cause fire and explosion, and cause damage to people and property of the business.

3. Cables used in the F&B industry

The following cables we recommend will meet all the highest requirements of the F&B industry. Control cables are designed to connect to machines, equipment as well as production lines in the factory. The cables below will not be altered by chemical agents and physical impact.

3.1 H05VV5-F control cables

H05VV5-F is the preferred cable for use in all spaces from dry to wet, room temperature extremes. This control cable is specialized for connection to machines, equipment, and production line storage areas. Due to its resistance to chemical influences such as detergents, acids, and grease, we recommend using (H) 05VV5-F ((N) YSLYÖ-JZ) for plants in the F&B industry.

_any_small.jpg)

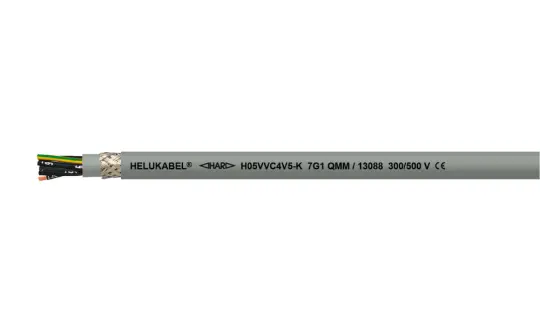

3.2 H05VVC4V5-K control cables

This is a control cable line at a voltage level of 300/500V with a sheath made of special PVC material, which is resistant to the impact of oil, minimizing the possibility of fire and explosion. At the same time, unwrapping is used to flip whether the material can withstand high temperatures or humidity. The core uses a high-quality copper core with Class.5 soft copper wire. Each wire will be designed with a flexible number of cores, ranging from 1 - 65 cores, and with a cross-section from 0.5mm2 to 2.5mm2. All core fibers inside will be twisted together, allowing the cable to be flexible, and easily bent at corners according to the characteristics of space without worrying about breaking the cable.

At HELUKABEL, we offer a wide range of control cables suitable for manufacturing plants in the F&B sector. The cable lines not only ensure to meet FDA and ECOLAB standards but also meet all the requirements of a specific industry. If you need advice on selecting wire lines for different areas of the factory, please contact our specialized engineers for specific advice on solutions for your field.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn