High – technology municipal waste to energy plant project in Bac Ninh

The project marks a meaningful milestone for us when accompanying TTCL Vietnam Co., Ltd - One of the leading integrated EPC general contractors in Vietnam on the journey to create green buildings for the community.

_newsroom_big.png)

Recently, HELUKABEL Vietnam has provided electrical instrument cables for the High–Technology municipal waste-to-energy plant project of Thang Long Energy Environment Joint Stock Company in Bac Ninh. The project marks a meaningful milestone for us when accompanying TTCL Vietnam Co., Ltd - One of the leading integrated EPC general contractors in Vietnam on the journey to create green buildings for the community.

Việt Nam is among the top 20 countries with the largest amount of waste in the world. According to the University of Georgia report, each year, about 8 million tonnes of plastic waste are disposed of in the ocean, of which 1.8 million tonnes come from Việt Nam. On average, each Vietnamese person releases 1.2 kg of solid waste into the environment per day, of which 16 percent is plastic waste.

From this situation, the problem of waste treatment and environmental protection is always the top concern of the Government and people. Among waste treatment solutions, building a waste incineration plant to generate electricity is a modern technology solution being applied in Vietnam in densely populated areas with a large amount of waste every day.

Waste management technology

The factory was built on an area of nearly 5 hectares in the waste treatment planning area of Bac Ninh province with the task of thoroughly solving the problem of daily-life waste and other types of solid waste generated daily throughout the province.

Once completed, on average, the plant will process about 600 tons of waste per day, with an estimated total generating capacity of 11.6MW.

TTCL Vietnam Co., Ltd. is the general contractor for design, procurement, construction, operation, and handover (EPC) in the High–Technology municipal waste-to-energy plant project. This company has 25 years of experience as an integrated EPC general contractor in Vietnam and Southeast Asia in the energy, petrochemical, petroleum, chemical-fertilizer, food, pharmaceutical, etc sectors.

_any_small.png)

The waste treatment process of the garbage factory is according to European standard lines. The basic waste treatment process in the line such as garbage is being collected and brought to the factory by vehicle and weighed at the weighing station. After that, the waste is taken to the treatment area and starts with the conveyor belt for feeding and sorting, producing RDF before being transferred to the incinerator. The incinerator performs the function of burning all the waste that has passed through the pre-treatment area to generate steam to turn the turbine to generate electricity.

The factory system will be controlled and accurately collects data through the DCS system - Distributed Control System. Besides the main DCS systems, the plant also has several other auxiliary systems: refrigeration system, DO oil system, compressed air system, raw water treatment, mineral treatment, wastewater treatment, gas monitoring waste, etc.

Project requirements

In the High–Technology municipal waste-to-energy plant project, Thang Long Energy Environment Joint Stock Company and TTCL Vietnam Co., Ltd. have selected the technology lines of Valmet Technology Oy and BMH Technology Oy from Europe. This project invests in all aspects from design - procurement - construction to technology lines, equipment, machinery, and materials used must meet quality standards, suitable for European lines. This investment is also the reason why HELUKABEL's power cables are selected to accompany the project with international quality standard certifications.

OTHER POSTS >>> 3 MAIN APPLICATIONS OF SUPER-PAAR-TRONIC 340-C-PUR SIGNAL CABLES

Instrument power cables used in this project are required to meet IEC standards for the copper core, as well as some requirements for the shield layer, the plastic layer of the sheath must ensure compliance with IEC fire retardant standards and UV resistance. In addition, the cord is subject to high temperatures due to operating in harsh environments.

When receiving requests related to technical issues for each area in the project, Duong Manh Ha, our sales engineer made suggestions on suitable product lines for the customer.

Power cables for signal measurement and control systems

For signal measurement and control systems in the Bac Ninh garbage factory, we supply 2 products such as HELUDATA® EN-50288-7 PVC/PVC OS 500 and H05V-K / (H)07V- K single cable.

- HELUDATA® EN-50288-7 PVC/PVC OS 500

To connect equipment such as sensor valves, pressure, and temperature sensors to programmable controllers for factory equipment PLC (Programmable logic controller), we provide customers with HELUDATA® EN-50288-7 PVC/PVC OS 500 cables. Data cable meets IEC 60332-3-22(*) flame-retardant standards and UV resistance, in particular, it also has good anti-interference inside thanks to the cores twisted into pairs, with the function of anti-cross interference. Moreover, the outer layer of the aluminum foil shield will help the wire have a good anti-interference function.

Find out more technical documents HERE .

- Cables for data systems

- PAAR-TRONIC-Li-2YCYv

HELUKABEL PAAR-TRONIC-Li-2YCYv data cables are the line used in RS 485 mode. Low capacitance cable, reinforced outer sheath, patented Maxi-Termi-Point®, and has EMC (limiting electrical interference from surrounding machines and equipment).

In particular, this data cable works well in the 80°C environment and has a shield with up to 85% coverage for very high anti-interference ability. The rope is UV resistant according to DIN EN ISO 4892 - 2, and weather resistant according to DIN EN ISO 4892 - 2, so it should be used outdoors. The cables are suitable for installation, buried directly in the ground.

Flame-retardant according to DIN VDE 0482 – 3321 – 1 – 2 / DIN EN 60332 – 1 -2 / IEC 60332 – 1 – 2 standards.

Find out more technical documents HERE .

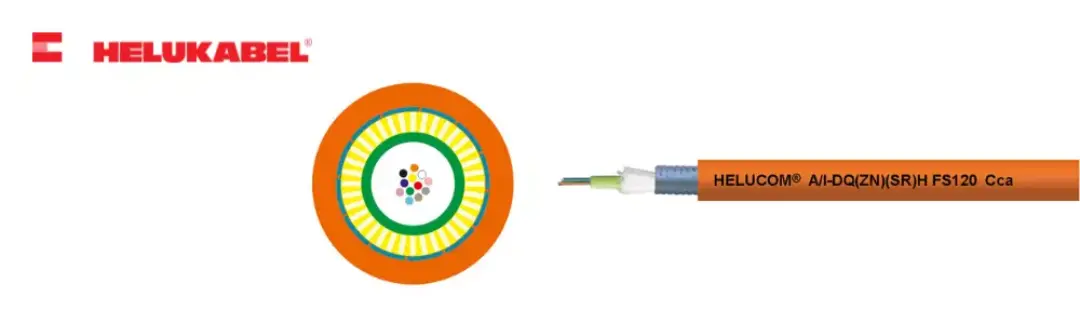

- HELUCOM® FS120 A/I-DQ(ZN)(SR)H Cca

In addition, when it comes to special products that we provide in the Bac Ninh garbage plant project, it is a must to mention HELUCOM® FS120 A/I-DQ(ZN)(SR)H Cca fiber optics cable. This fiber optics cable possesses advantages that very few domestic cables can meet such as:

- Halogen-free according to standard 60754-2, helping to ensure the safety of people and property in the factory.

- Fiber optic cable meets the flame-resistance standard according to IEC 60332 – 1 and -3

- Low smoke density according to IEC 61034

- Longitudinally water-tight acc. to IEC 60794-1-2-F5

- Cable, laterally water-tight

- Anti-UV (UV-resistant)

- Our German-made HELUCOM® FS120 fiber optic cables have been successful in ensuring the functional integrity of the cables according to IEC 60331-25 flame-retardant standards for 120 minutes (flame temperature up to 750 °C) using exceptional design and quality materials.

Moreover, in this project, we were also appreciated for on-time delivery with the support of Duong Manh Ha, Sales Engineer of HELUKABEL Vietnam, and related logistics departments.

Find out more technical documents HERE .

OTHER POSTS >>> WHAT TYPE OF CABLES ARE USED UNDER THE SEA?

Find out more about HELUKABEL control cables and accessories on TIKI .

_welcome_slider.png)