How many shielding layers can an instrument cable have?

The structure of an instrument cable is designed with multiple shielding layers to minimize interference, protect the conductors, and ensure stable signal transmission under various operating conditions.

1. Shielding layers in instrument cables

An instrument cable can have one to three shielding layers, each serving a specific function depending on technical requirements and the working environment.

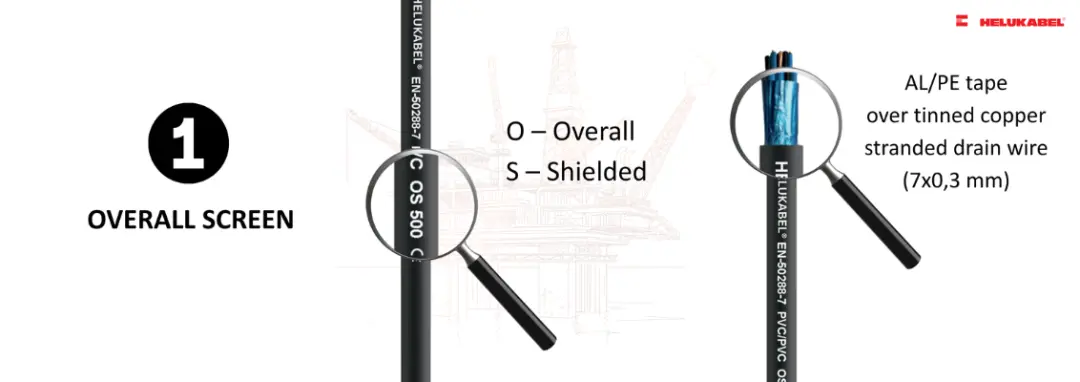

1.1. Overall screen

This is the most common and basic structure, where the entire core bundle is surrounded by an aluminum foil layer that acts as a shield. This “overall screen” protects all conductors at once, maintaining signal stability in applications with moderate levels of electromagnetic interference (EMI), such as control or monitoring systems in industrial facilities.

1.2. Individual screen

At a higher level, each pair of signal conductors is individually shielded. This structure significantly reduces crosstalk between signal pairs, which can otherwise distort measurement data or control signals.

When combined with an overall screen, the individual screen provides dual-layer protection, safeguarding each channel independently while shielding the entire cable. This configuration is ideal for applications requiring high precision and stable signal quality.

1.3. Armour

In addition to the shielding layers, many instrument cables include a mechanical armour layer, typically made from galvanized steel wires wrapped around the cable core. The main purpose of the armour is to enhance mechanical strength, allowing the cable to withstand impact, tension, or harsh installation conditions such as underground routing or exposed outdoor environments.

Beyond physical protection, the armour also helps maintain signal integrity by preventing mechanical deformation from affecting the internal conductor structure.

2. Four instrument cable types of HELUKABEL

Based on the combination of shielding and armour layers, HELUKABEL’s instrument cables are categorized into four types: OS, IOS, OSA, and IOSA.

2.1. HELUKABEL® Instrument EN-50288-7 OS

OS (Overall Screened) cables feature a single overall aluminum–polyethylene (AL/PE) tape screen surrounding all conductors, with a tinned copper stranded drain wire (7x0.3 mm). This design provides reliable EMI protection for environments with moderate electrical interference. The HELUKABEL® EN-50288-7 PVC/PVC OS 500 is a representative example of this type.

2.2. HELUKABEL® Instrument EN-50288-7 IOS

IOS (Individual and Overall Screened) cables offer both individual pair shields and an overall screen. This dual-screen configuration minimizes crosstalk and ensures strong protection against external EMI - making it ideal for precise control systems or areas with heavy electrical equipment. In the HELUKABEL® EN-50288-7 PVC/PVC IOS 500, each pair, triad, or quad is individually screened with aluminum–polyethylene (AL/PE) tape and a tinned copper stranded drain wire (solid 0.6 mm), ensuring optimal signal stability and interference resistance.

2.3. HELUKABEL® Instrument EN-50288-7 OSA

OSA (Overall Screened and Armoured) cables combine an overall shield with a steel wire armour layer, enhancing both electrical and mechanical protection. This structure is suitable for fixed installations or underground applications.

In the HELUKABEL® EN-50288-7 PVC/PVC OSA 500, the steel wire armour (SWA) is positioned between two PVC jackets (PVC/OS/PVC/SWA/PVC), reinforcing durability and performance even under harsh conditions.

2.4. HELUKABEL® Instrument EN-50288-7 IOSA

IOSA (Individual and Overall Screened, Armoured) represents the most comprehensive configuration, offering both individual and overall screening combined with steel wire armour. Products such as the HELUDATA® EN-50288-7 PVC/PVC IOSA 500 are ideal for high-EMI environments and applications requiring maximum mechanical protection, such as chemical plants, oil & gas facilities, or outdoor industrial sites.

3. Choosing the right instrument cable structure

Selecting the right instrument cable depends on two key factors: the level of electromagnetic interference and the installation environment.

For low-interference environments and standard installations, OS cables provide an economical and sufficient option. For higher accuracy and reduced crosstalk, IOS cables are recommended. For installations exposed to physical impact or requiring underground routing, OSA or IOSA cables offer both shielding and mechanical protection.

With the OS, IOS, OSA, and IOSA series, HELUKABEL delivers comprehensive solutions that meet every level of requirement, from simple signal transmission to complex industrial systems. Contact us for detailed consultation and product recommendations tailored to your needs.

>>> Or order on our official e-commerce channels including Tiki , Shopee , Lazada and Zalo Mini App !

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |