Differences between standard and custom cables

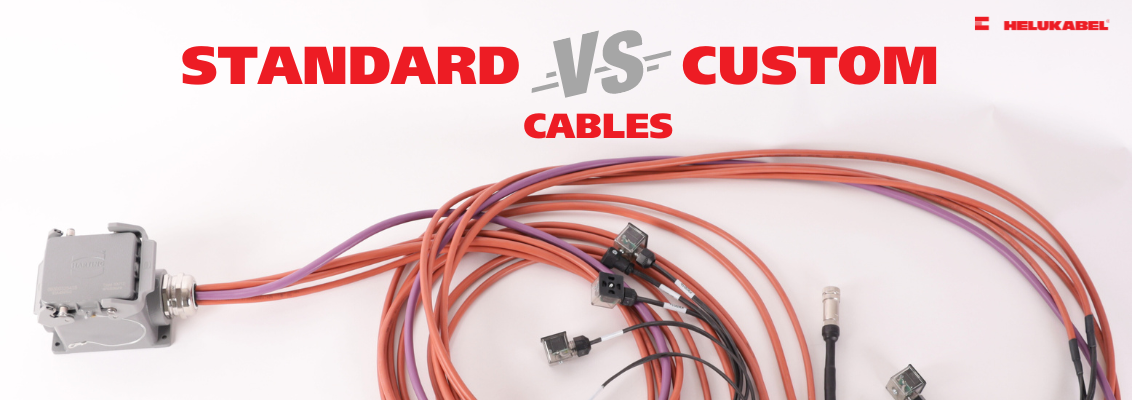

Standard cables perform well in most applications that machine users require. However, in numerous instances, a custom cable becomes indispensable to successfully finalize a project, as it can adapt to the specific demands of the application.

1. Standard and custom cable comparison

Standard and custom cables differ notably in their construction and in various other production-related aspects.

1.1. Standard cables

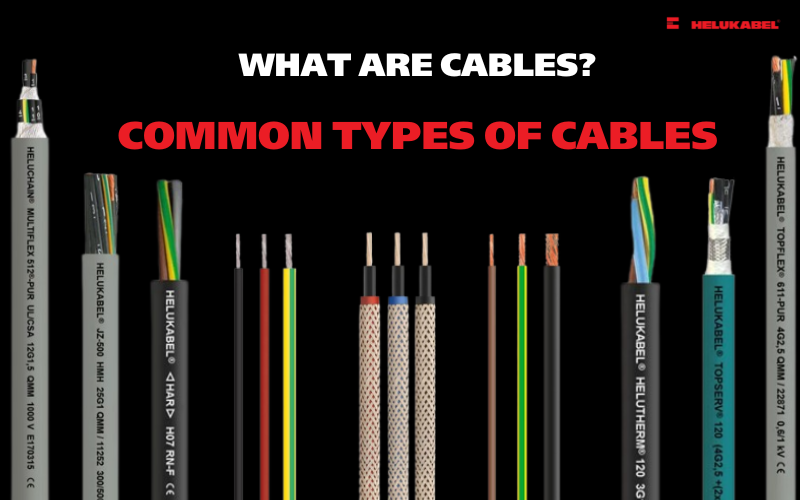

Standard cables are commonly used in various applications, each designed with specific technical features to suit its intended purpose. These cables are typically categorized into subtypes like control cables, data cables, audio cables, etc.

Different classifications of standard cables offer features such as anti-interference, water resistance, fire resistance, flame retardancy... You only need to select the appropriate type of cable and specify the correct parameters (such as number of cores, number of wire pairs, cross-section...) to be assured of getting the suitable cables for your needs.

Once classified, standard cables undergo mass production for distribution in the market. In contrast to custom cables, standard cables are more cost-effective to manufacture and generally encounter fewer compatibility issues.

For example, NSSHÖU 4G16 cable is a rubber-sheathed cable according to DIN VDE 0250 Standard, withstanding temperatures from -40°C to 80°C. The wire's minimum bend radius during flexing is 10 times bigger than its diameter. The cable has tinned copper conductors and rubber core insulation. The cores meet DIN VDE 0293-308 Standard, up to 5 colored cores and from 6 cores, black with continuous white numbering.

In terms of characteristics, NSSHÖU 4G16 cable has high insulation resistance, ozone resistance, hot penetration resistance and low abrasion. At the same time, this cable also can protect machinery from oils, fats, and chemicals. Cable lifespan is guaranteed even under harsh operating conditions. Therefore, it is suitable as a connecting cable for very high mechanical stress in underground mining and tools for use in industries and outdoor use.

1.2. Custom cables

In some instances, standard cables may not align with the user's machine design specifications. Certain industries necessitate cables with a more tailored structure and cross-section. In such cases, opting for a custom cable proves to be the most optimal solution.

The parameters and materials of this type of cable have been adjusted to provide features suitable for special environments. Due to the bespoke nature of each requirement, custom cables are not mass-produced. Moreover, in terms of cost, manufacturing custom cables is significantly pricier than standard ones due to the need to integrate multiple materials.

For example, standard cables lack SWA (steel wire armor). Thus, when customers require cables for environments prone to mechanical damage and corrosion, standard cables are modified with this additional layer to fulfill the requirement.

Recently, we HELUKABEL Vietnam have completed a custom cable order according to customer requirements. Specifically, the customer's project needed 5 cables with 20 cores into 1 dedicated connector and 10 end connectors. Among them, there is 1 CAN Bus cable which has 4 cores with a cross-section of 0.5mm2. The remaining 4 cables are SiHF silicon ones, each has 4 cores, each core has a cross-section of 1mm2, providing compatibility for the customer's device.

2. Various choices of cables at HELUKABEL

At HELUKABEL, we offer a wide range of standard cables suitable for different projects, such as:

· H05V-K and H07V-K single core cable

· …

Additionally, if you find yourself in need of custom cables for your projects, our team of experienced and specialized engineers is here to offer advice and tailor the optimal solution for each project. With a diverse product portfolio, we can quickly customize electric cable products to meet international quality standards such as VDE, UL, IEC, TUV, and more.

For detailed guidance on HELUKABEL’s cables, schedule a consultation appointment with our engineer here or reach out to us at:

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn