What are coaxial cables? Structure and types of coaxial cables

Coaxial cables are a popular choice for transmitting various signals, including radio, television, and video surveillance. Thanks to their low attenuation, low electrical resistance, and low noise characteristics, they are especially suited for professional audio applications.

1. Understanding coaxial cables

1.1 Radio Frequency - the foundation of modern connectivity

RF (Radio Frequency) refers to high-frequency electromagnetic signals that play a core role in wireless communication systems. In the past, RF was typically limited to frequencies ranging from a few kHz up to around 1 GHz, such as AM and FM radio. Today, however, RF has expanded to include microwave and millimeter-wave frequencies, with ranges extending up to 300 GHz.

The rapidly growing global demand for bandwidth is driving systems to operate at higher frequencies, where data can be transmitted faster, devices can be more compact, and spectrum congestion is reduced. Unlike conventional electrical signals, RF and microwave signals are extremely sensitive:

- They experience significant attenuation during transmission

- They are prone to reflection and signal distortion if impedance matching is poor

- They are highly susceptible to EMI from surrounding environments

As a result, coaxial cables, with their specialized structure, have become an essential choice in most RF and microwave systems.

1.2 What are coaxial cables?

A coaxial cable is a type of cable designed to efficiently transmit electrical signals, particularly high-frequency signals. Thanks to this capability, coaxial cables are widely used in applications such as television antennas, internet connections, wireless communications, and video surveillance systems.

A key advantage of coaxial cables is their excellent shielding performance, which minimizes the impact of external interference and reduces signal loss during transmission. In addition, coaxial cables offer good mechanical flexibility, making them easy to install in confined spaces or along complex routing paths. This combination of performance and ease of installation is why coaxial cables are highly valued in both commercial and industrial applications.

1.3 Structure of coaxial cables

The main components of a coaxial cable include: inner conductor, insulating dielectric, outer conductor/shield, and outer sheath.

- Inner conductor: The inner conductor is typically made of copper wire. In most cases, it is a single solid conductor. However, for certain applications - such as when the cable is subject to repeated flexing or when extremely low insertion loss is required - coaxial cables may be designed with a stranded (multi-wire) conductor.

- Insulating dielectric: Between the inner conductor and the outer conductor is the insulating dielectric layer. This dielectric not only maintains the physical separation between the two conductors but also determines many of the key electrical characteristics of the cable. The dielectric may be solid or semi-air spaced. This structure can take the form of long hollow tubes within the dielectric material, a spiral wrap of dielectric tape, or a foam construction, in which air makes up a significant portion of the material. The most commonly used materials include PE, foam PE, and Teflon (PTFE).

- Outer conductor / metallic shield: The outer conductor is typically made of a braided copper shield, which provides the cable with flexibility and mechanical pliability. If the outer conductor is solid, the cable becomes much less flexible, except in certain specialized designs such as semi-rigid coaxial cables. To enhance shielding effectiveness, some coaxial cables use double or even triple layers of braided shielding. This is usually achieved by layering braided shields on top of one another or by combining them with copper foil or metallic tape. Increasing the shielding layers significantly reduces external interference pickup and signal radiation leakage.

- Outer sheath: This layer has no electrical function, but it serves to protect the cable from dirt, moisture, and mechanical damage such as abrasion or impact. A wide variety of materials are used, selected according to the environmental conditions of use, including resistance to solvents, abrasion resistance, moisture resistance, and the ability to withstand different operating temperature ranges.

2. Applications of coaxial cables

Coaxial cables are used in many surveillance, satellite, and radio systems, as well as telecommunications infrastructure.

Coaxial cables have been a fundamental part of communication infrastructure for decades. Their ability to reliably transmit data over long distances makes them indispensable across a wide range of industrial sectors.

- Cable television and broadband internet: Despite the rapid growth of fiber optics, coaxial cables continue to play a key role in delivering cable TV and broadband internet services. They provide high bandwidth and stable signal transmission and are particularly effective in rural and suburban areas.

- Security and surveillance systems: Thanks to their strong resistance to electromagnetic interference, coaxial cables ensure clear and stable video signals. In industrial environments, they are used to connect multiple cameras across large facilities, helping to enhance operational safety and monitoring efficiency.

- Satellite and radio communications: Satellite antennas and radio transmission equipment rely on coaxial cables to carry signals from the antenna to the receiver. This application is especially critical in remote areas and in military operations, where reliable long-distance communication is essential.

- Industrial automation and control: In factories and production lines, coaxial cables are used to transmit control signals and data between machinery and central control systems. Their high durability and effective shielding help reduce downtime and maintenance costs.

- Telecommunication: Coaxial cables are used in backbone and distribution networks, connecting base stations, data centers, and local exchanges. This ensures high-speed data flow and network reliability, supporting the rapid development of 5G technology and IoT devices.

3. Classification of coaxial cables

Coaxial cables are designed in a variety of configurations depending on their intended applications. Shorter cables are commonly used in residential and consumer applications, such as audio-visual (AV) systems or personal Ethernet connections. In contrast, longer coaxial cables are used to connect large-scale radio and television networks or long-distance telecommunication links.

3.1 Hardline coaxial cables

Hardline coaxial cables are constructed with a center conductor made of copper, silver, aluminum, or steel, combined with a shield made from one of these materials. These cables have a large diameter (≥ 1/2 inch) and are used in applications that require high-power signal transmission and high mechanical strength, such as military communications or radio broadcasting from ground-based transmitters to elevated antennas or aerial receivers.

3.2 Radiating/Leaky coaxial cables

This type of cable has a structure similar to hardline cable, but the shield is engineered with slots that are precisely designed according to specific wavelengths or RF frequencies. This design allows radio, cellular, and Wi-Fi communication in areas where free-space electromagnetic radiation typically cannot propagate. Such cables are widely used in tunnels, mines, large buildings or building complexes, along railway lines, and in underground shopping malls, where they help extend wireless coverage and ensure reliable network availability.

RG 59 B/U TWIN Coaxial Cable

3.3 Twinax cables

This type of cable has a structure similar to a coaxial cable, but instead of a single center conductor, it contains two conductors. Twinax is used for short-distance, high-speed signal transmission, typically in network equipment with SFP+ interfaces, servers, and data centers.

3.4 Triax cables

Triax cable has a structure similar to a standard coaxial cable but includes an additional insulation layer and a second outer conductor/shield.

Compared to conventional coaxial cables, Triax is more expensive, but in return it offers higher bandwidth and superior noise immunity. This type of cable is commonly used in professional broadcast production and in environments with strong EMI.

3.5 Semi-rigid cables

Semi-rigid cables use a PTFE dielectric and a solid metal shield instead of a braided shield. This construction provides superior dielectric properties, helping to improve signal transmission performance at high frequencies.

However, compared to fully rigid cables, semi-rigid cables are limited in terms of physical size and operating frequency range. As a result, they are mainly used in precision RF applications with moderate power requirements.

3.6 Rigid cables

This type of cable is constructed from two concentric copper tubes with a PTFE dielectric in between. The structure is secured at both ends of the cable and at multiple points along its length to prevent bending or deformation.

Rigid coaxial cables are significantly larger than semi-rigid cables and are capable of handling much higher power levels, making them suitable for multi-channel television transmission and FM broadcasting applications.

3.7 RG coaxial cables

RG coaxial cables are used as interconnect cables in high-frequency signal transmission systems, particularly in wireless communications and data transmission applications where low signal attenuation is required. They are commonly applied in RF and microwave transmission, data communication, as well as instrumentation and control systems.

Many RG cable types are designed in accordance with military specifications (MIL-Spec) and are typically identified by their corresponding RG designations.

4. Features of RG coaxial cables

RG 11 A/U coaxial cable

Among the various types of coaxial cables available, RG coaxial cable is considered the most common and widely used on the market. Thanks to clearly standardized specifications covering construction, impedance, and electrical characteristics, RG cables provide stable and reliable signal transmission across a wide range of environments and applications.

4.1 What are RG coaxial cables?

RG cable, also known as Radio Guide cable, is a type of coaxial cable with military origins, first developed during World War II. The designation “RG” stands for Radio Guide, a term used within the U.S. military’s radio frequency (RF) cable classification system.

RG coaxial cables are designed for the transmission of radio frequency signals and are available in many different variants, each with specific technical characteristics tailored to particular applications. These applications range from telecommunications and broadcast radio–television systems to specialized instrumentation and control systems.

4.2 MIL standards

MIL standards (Military Specifications and Standards) are a system of standards issued by the U.S. Department of Defense and are widely applied to ensure the performance and quality of coaxial cables.

At first glance, MIL part numbers may appear complex, but in reality, each element of the designation carries a specific technical meaning. Once the structure of the part number is understood, it becomes possible to accurately identify the cable’s characteristics and its intended application.

4.3 Structure of RG coaxial cable designations according to MIL standards

MIL codes are usually divided into several parts:

1. "MIL-C-17"

The designation always begins with MIL-C-17, indicating that the product is a coaxial cable manufactured in accordance with U.S. military standards. This is a key identifier for the applicable standard family.

2. "RG"

Following this is the RG designation, an abbreviation for “Radio Guide”, which identifies the cable type. Examples include RG-58 and RG-59. The number following “RG” is related to the cable’s technical characteristics, particularly its impedance and overall diameter.

- RG-58: 50 Ω impedance

- RG-59: 75 Ω impedance

3. Additional symbols (A/U, B/U, …)

The letters and symbols that follow indicate the cable version or level of revision:

- A: the first version

- B: improved version

- U: stands for Universal, meaning suitable for general use

4.4 Common types of RG coaxial cables

Each RG designation represents a specific set of physical specifications, including the wire gauge of the center conductor, the thickness and material of the inner insulation (dielectric), the shielding construction, and the size and type of the outer sheath.

| Classification | Impedance | Characteristics |

| RG-6 | 75 | Widely used for both indoor and outdoor installations. It offers good flexibility, is easy to bend, and simple to install. RG-6 is commonly used for A/V signals, HDTV, and broadband transmission. |

| RG-11 | 75 | RG-11 is a large-diameter, thick coaxial cable and is less flexible than RG-6 or RG-59. It is well suited for high-resolution video transmission and high-frequency applications, and it can transmit signals over longer distances while maintaining signal stability. |

| RG-58 | 50 | The lower impedance makes RG-58 suitable for signal amplification in low-frequency audio applications, such as radio communication and two-way radios. |

| RG-59 | 75 | RG-59 has a smaller diameter than RG-6, making it suitable for low-frequency, indoor, and short-distance applications. Similar to RG-6, RG-59 is used for video transmission, television, CCTV systems. However, its smaller center conductor results in lower signal quality, limiting it to lower frequencies and causing higher signal attenuation compared to RG-6. |

5. HELUKABEL coaxial cable portfolio

HELUKABEL’s coaxial cable portfolio is specifically designed for the transmission of video and RF signals from sources such as antennas, satellite receivers, cameras, and recording devices to monitors, televisions, controllers, or projectors, supporting both analog and digital signal transmission.

The product range includes a wide variety of coaxial cables engineered to meet different impedance requirements, frequency ranges, technical standards, and real-world applications. These solutions are well suited for broadcasting systems, surveillance and CCTV, industrial video, measurement technology, and RF communication systems.

5.1 RG6, RG11, RG59 coaxial cables...

| RG cable | Impedance (Ω) | Outer diameter (mm) | Inner conductor | Outer conductor | Part number |

| RG 6 A/U | 75 | 8.4 | Steel/copper, bare | Silver-plated copper Copper, bare | 40001 |

| RG 11 A/U | 75 | 10.3 | Tinned copper | Copper, bare | 40002 |

| RG 58 C/U | 50 | 5.0 | Tinned copper | Tinned copper | 40003 |

| RG 59 B/U | 75 | 6.2 | Steel/copper, bare | Copper, bare | 40004 |

| RG 62 A/U | 93 | 6.2 | 40005 | ||

| RG 71 B/U | 93 | 6.2 | Copper, bare Tinned copper | 40006 | |

| RG 174 A/U | 50 | 2.8 | Steel/copper, bare | Tinned copper | 40197 |

| RG 178 B/U | 50 | 1.8 | Steel/copper, silver | Silver-plated copper | 40007 |

| RG 179 B/U | 75 | 2.5 | 40008 | ||

| RG 180 B/U | 95 | 3.7 | 40009 | ||

| RG 187 A/U | 75 | 2.6 | 40010 | ||

| RG 213 | 50 | 10.3 | Copper, bare | 40012 | |

| RG 59 B/U TWIN | 75 | 12.6 | Steel/Copper, bare | Copper, bare | 400190 |

5.2 Halogen-free RG coaxial cables

| RG cable | Impedance | Outer diameter (mm) | Inner conductor | Outer conductor | Part number |

| 11 A/U | 75 | 10.3 | Tinned copper | Copper, bare | 40190 |

| 58 C/U | 50 | 5.4 | Tinned copper | Tinned copper | 40191 |

| 59 B/U | 75 | 6.4 | Steel/copper, bare | Copper, bare | 40192 |

| 62 A/U | 93 | 6.4 | 40193 | ||

| 71 B/U | 93 | 6.9 | Copper, bare Tinned copper | 40194 | |

| 213 U | 50 | 10.3 | Copper, bare | Bare copper | 40195 |

| 214 U | 50 | 10.8 | Silver-plated copper | 2x silver-plated copper | 40196 |

5.3 CATV coaxial cables

| CATV cable | Impedance (Ω) | Outer diameter (mm) | Inner conductor | Outer conductor | Part number |

| ALG | 75 | 10.5 | Copper, bare | Aluminum-coated polyester foil on both sides | 40139 |

| ALG-T | 75 | 2.8 | 40140 | ||

| A-2YK2Y1 iKx 1.1/7.3 | 75 | 11 | Welded copper tube | 40142 | |

| A-2Y0K2Y1 nKx 2.2/8.8 | 75 | 12.5 | 40143 | ||

| A-2Y0K2Y1 qKx 3.3/13.5 | 75 | 17 | 40144 | ||

| A-2Y0K2Y1 sKx 4.9/19.4 | 75 | 24.4 | 40179 |

5.4 SAT coaxial cables

SAT coaxial cables are used to connect a satellite antenna to a TV receiver or to a cable television (CATV) system. In some installations, the cable may be used in combination with intermediate amplifiers, splitters, or switching devices to maintain signal quality over longer distances or across multiple connections.

This type of cable always features a standard impedance of 75 ohms and is available with various shielding configurations, allowing it to meet different EMI protection requirements and installation conditions for specific system applications.

SAT COAXIAL CABLE ALG (40151)

SAT/BK COXIAL CABLE A+ (400197)

SAT COXIAL CABLE (40021)

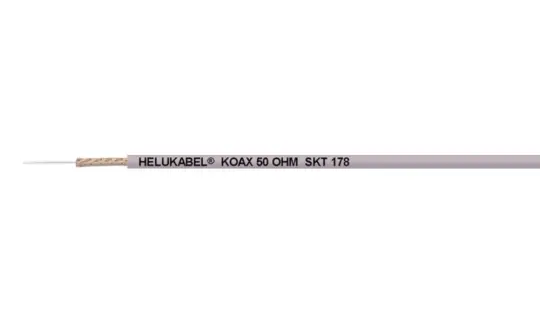

5.5 SKT coaxial cables

| SKT Cable | Impedance (Ω) | Outer diameter (mm) | Part number |

| COAXIAL CABLE SKT 178 | 50 | 2.8 | 400314 |

| COAXIAL CABLE SKT 179 | 75 | 4.3 | 400312 |

| SKT 58 Coaxial Cable | 50 | 5 | 400313 |

If you still have questions, don't hesitate to contact HELUKABEL Vietnam's team of engineers for detailed answers.

Contact Information HELUKABEL Vietnam

| HELUKABEL Vietnam 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City, 700000, Vietnam | Phone:

+84 28 77755578 Email: info@helukabel.com.vn | Connect with us on |

| Order through our online channels Tiki | Shopee | Lazada | Product finder | ||