ECOLAB®-certified cables and accessories for F&B industry

ECOLAB-certified control cables can withstand the rigorous cleaning and sanitization processes in the F&B industry, helping to prevent contamination and ensure food safety. Learn more about this standard and the ECOLAB-compliant products in the article below!

Production processes in the F&B industry are governed by strict hygiene and food safety regulations. The most important requirement is to prevent bacteria and foreign substances from forming or coming into contact with food. Therefore, control cables, as well as connectors and cable accessories used in this industry, must meet stringent hygiene and durability standards suitable for such demanding environments.

1. Requirements for control cables in the F&B industry

Few industries face hygiene challenges as rigorous and complex as the F&B sector. The frequent use of high-pressure water, aggressive cleaning agents, and disinfectants to maintain hygiene can damage electrical wiring and control cables used in this environment.

To avoid operational disruptions, manufacturers are required to use specialized industrial cable solutions that are specifically engineered to meet the industry's hygiene and safety standards.

1.1 Temperature resistance

The production environment in the F&B industry often experiences extreme temperature fluctuations - from hot water used for sterilizing equipment to cold storage areas for food preservation. Therefore, electrical cables used in this industry must be engineered to withstand harsh temperatures, ensuring long-term durability and stable performance.

>>See more: Temperature-resistant cables for harsh environment

1.2 Chemical resistance

Food processing equipment is regularly exposed to strong chemical-based cleaning agents to maintain hygiene standards. Over time, these chemicals can corrode control cables, leading to equipment failures. In many cases, standard cable sheaths are not resistant to such aggressive substances. Thus, using cables with high chemical resistance is essential to ensure uninterrupted operations and system reliability.

1.3 Water resistance and washdown durability

In F&B facilities, cold floors and hot-water cleaning processes often lead to condensation. Therefore, cables and connectors used in these areas must offer excellent ingress protection, with sealed and robust construction. Cables with pre-molded connectors and locking mechanisms enable quick and secure plug-and-play installation while preventing the intrusion of water, oil, dust, and other contaminants. Additionally, continuous flexing and tensile strength ensure long-lasting performance in demanding production environments.

1.4 High flexibility

Industrial control cables with smaller diameters are ideal for installations in tight spaces with small bending radii. This is especially beneficial in F&B plants, where equipment is densely arranged and space is limited. High flexibility simplifies cable routing, installation, and maintenance while ensuring stable electrical connections. It also allows the system to adapt more easily to dynamic production settings, ultimately improving overall operational efficiency.

2. What is the ECOLAB® standard?

2.1 What is ECOLAB?

Ecolab Inc. is a global leader in professional hygiene and disinfection solutions across various industries, including the food and beverage (F&B) sector. For electrical cable products, ECOLAB provides material durability tests that evaluate a cable’s resistance to aggressive cleaning chemicals used in F&B environments.

2.2 ECOLAB cable quality testing

ECOLAB’s tests for the F&B industry are designed to assess the corrosion resistance of control cables commonly used in hygienic production settings. The testing procedure involves exposing cable samples to a wide range of cleaning and disinfecting chemicals such as chlorine, sulfuric acid, hydrochloric acid, hydrofluoric acid, and other disinfectants.

Samples are immersed in these solutions for several days and then undergo visual inspection and mechanical property evaluation. Materials that pass the test must show no signs of cracking, blistering, or significant mechanical degradation.

The ECOLAB testing process involves several common cleaning and disinfecting agents used in the F&B industry, including:

- Alkaline disinfectants with active chlorine (P3-topax 66)

- Acidic foaming cleaners (P3-topax 52)

- Alkaline, chlorine-free foaming cleaners (P3-topactive 200)

- Foaming peroxyacid-based disinfectants (P3-topactive Okto)

- Deionized water, used as a control reference

2.3 Applications requiring ECOLAB®-certified cables

Certain environments demand cables and components that are not only durable but also antimicrobial, corrosion-resistant, and easy to clean to maintain the highest hygiene standards in food and beverage production. Typical applications include:

- High-pressure washdown areas

- Automatic packaging and bagging machines

- Electronic control systems

- Cable carriers and energy chains

- Power supply to fans, pumps, motors, and handheld tools

- Conveyor systems

- Refrigerators, cooling units, and freezers

- Canning and filling lines

- Any application requiring control of fungi, bacteria, or mold growth

3. Areas where ECOLAB-certified control cables are required in the F&B industry

In F&B manufacturing facilities, there are three key hygiene-critical zones where the use of ECOLAB-certified control cables is essential: the hygienic design zone, the spray zone, and the non-product zone.

3.1 Hygienic design zone

Also known as the product zone or preprocess-integrated zone, this is the area where food comes into direct contact with motors, actuators, and other components - essentially where food is processed and handled.

In this zone, motors and equipment are cleaned multiple times per day using aggressive cleaning agents and must comply with strict hygiene protocols. Therefore, special materials and design principles are applied to ensure fully sealed enclosures, stable operation, and surfaces that do not support bacterial growth.

3.2 Spray zone

Located near the production area (also referred to as close-to-production), the splash zone is where food particles or droplets may splash back into the process, posing a risk of cross-contamination. Electrical components in this zone must also adhere to rigorous cleaning procedures, depending on the specific type of product being manufactured.

3.3 Non-product zone

This is the area where there is no direct contact with food products - clearly distinguished from the hygienic design and spray zones, where contamination risk is higher.

Although food does not come into contact with this zone, the principle of contamination prevention still applies to maintain a clean and safe production environment across the entire facility.

4. ECOLAB®-certified control cables for the F&B industry

HELUKABEL is widely recognized as a trusted manufacturer offering a broad portfolio of high-performance electrical cables. These products are engineered for durability, reliability, and resistance to harsh chemical, thermal, and mechanical conditions—factors that often degrade cable quality in demanding environments.

To meet the increasingly stringent hygiene and contamination-resistance requirements of the F&B industry, HELUKABEL offers a wide selection of ECOLAB®-certified control cables, including:

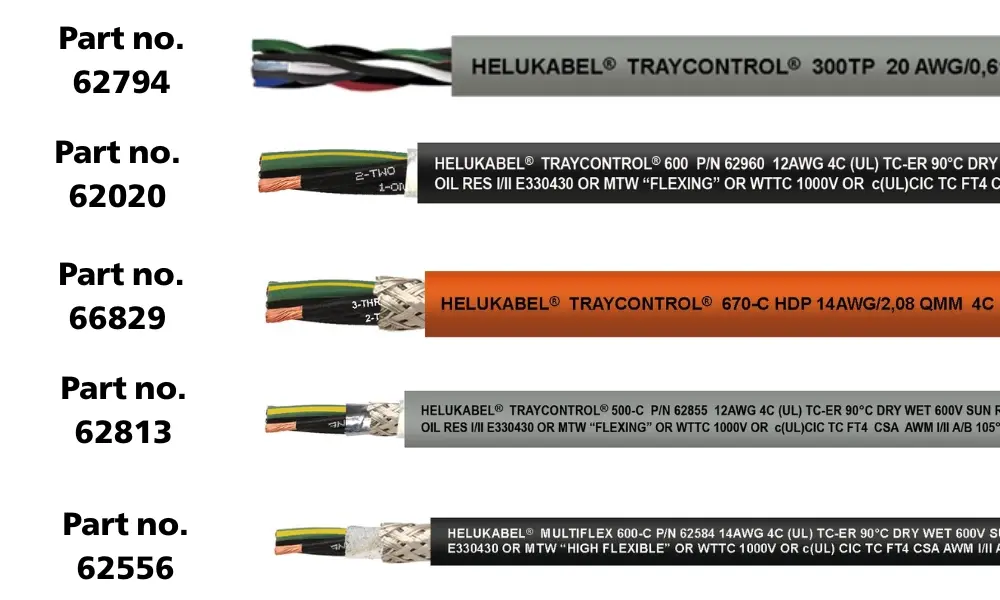

4.1 PVC control cables

PVC remains one of the most widely used materials for control cables. Thanks to advances in material technology, HELUKABEL’s ECOLAB-certified PVC control cables offer significantly improved technical properties, including: durability, thermal resistance, abrasion resistance…

>>See more: HELUKABEL's portfolio for control cables

| Variants | Properties | Part. no | |

| TRAYCONTROL® 300 | 300-C (shield) 300 TP (twisted pair) 300-C TP (shield, twisted pair) | Oil Res I/II, exposed run: PLTC-ER, ITC-ER, CM, CMG, NFPA 79 | 62625 |

| TRAYCONTROL® 500 | 500-C (shield) 530 (blue conductor) 550 TPE (blue conductor, TPE outer sheath) | 600/1000V, Oil Res I/II, exposed run: TC-ER, PLTC-ER, ITC-ER, NFPA 79 | 63079 |

| TRAYCONTROL® 600 | 600-C (shield) | 600/1000V, Oil-resistant, TC-ER, PLTC-ER, ITC-ER, NFPA 79 | 62020 |

| TRAYCONTROL® 670 HDP | 670-C HDP | 600/1000V, Oil-resistant, open installation (TC-ER), NFPA 79 Edition 2012 | 66820 |

| MULTIFLEX 600 | 600-C (shield) | Oil Res I/II, exposed run: TC-ER, PLTC-ER, ITC-ER, NFPA 79 | 62502 |

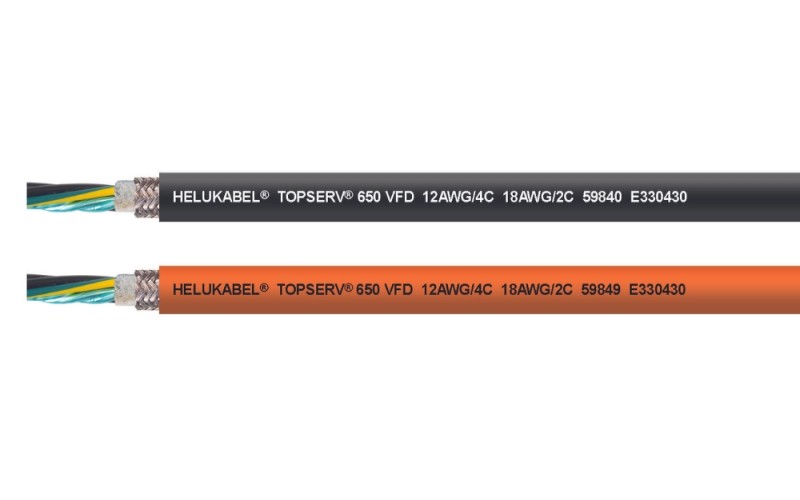

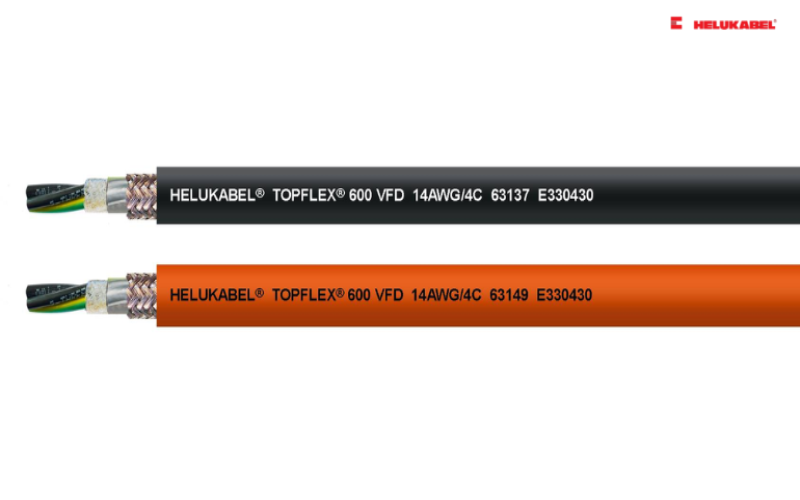

4.2 VFD control cables

| Variants | Properties | |

| TOPFLEX® 600 VFD | 650 VFD (1 or 2 control pairs) | 600/1000V, EMC-preferred Type, Flexible Motor Power Supply Cable, Oil-resistant, NFPA 79 |

| TOPFLEX® 1000 VFD | 600/1000V, EMC-preferred Type, Flexible Motor Power Oil-resistant, NFPA 79 | |

| TOPSERV® 600 VFD | 650 VFD | 600/1000V, EMC-preferred Type, Flexible Motor Power Supply Cable, Oil-resistant, NFPA 79 |

4.3 Servo, motor, feedback cables

Several ECOLAB®-certified servo, motor, and feedback cables suitable for use in the F&B industry include:

- TOPSERV® PUR 109

- TOPSERV® PUR 113

- TOPSERV® PUR 121

- TOPGEBER® 512 PUR

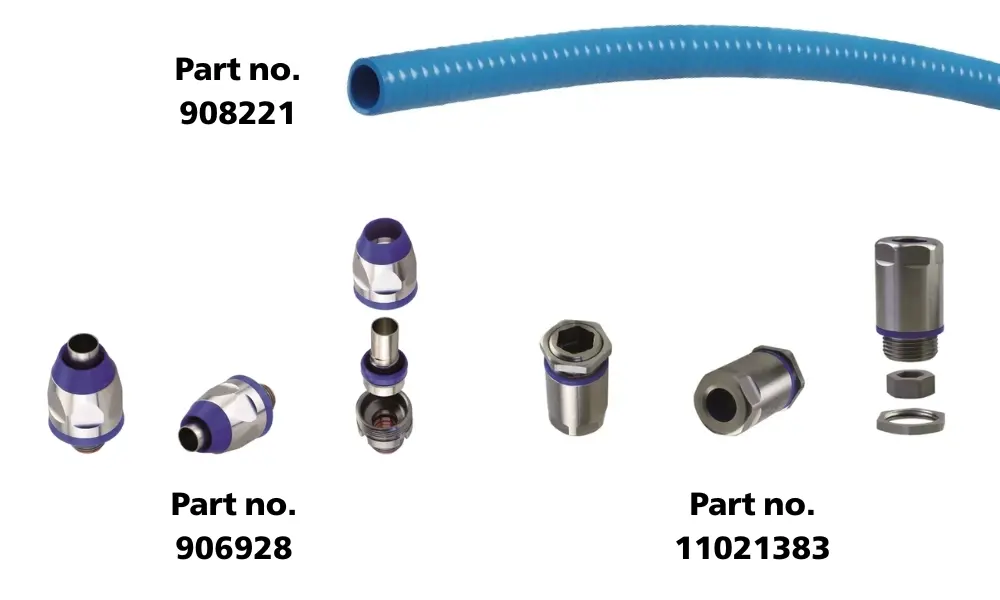

4.4 Cable accessories for F&B industry

In addition to control cables, HELUKABEL also offers a range of ECOLAB®-certified cable accessories, such as:

| Properties | Part no. | |

| HELUTOP® HT-Clean stainless steel cable gland | Temperature range: -20°C to +100°C, 40°C to +150°C (short time) Ingress Protection: IP 68 - 5 bar, 30 min. | 11021383 |

| HELUTOP® HT-Clean-EMV stainless steel cable gland | 906918 | |

| Sealtite® NMFG-Clean corrugated tube | Material: Special polyvinyl chloride (PVC) according to FDA CFR 21 and NSF 51 (USA standard) with integrated Hard PVC spiral | 908211 |

| LT-FG-Clean stainless steel- conduit gland | Temperature range: -45°C to +105°C Ingress Protection: IP 68 - 40 bar | 906928 |

5. FAQs about control cables and accessories in the F&B industry

5.1 Why do electrical cables used in the F&B industry need to be resistant to oils and chemicals?

In the F&B industry, cables must not only ensure electrical safety but also withstand harsh operating conditions — especially exposure to oils, cleaning agents, and disinfectants. These substances are frequently encountered during production, cleaning, and maintenance processes. Specifically, cables are regularly exposed to:

- Engine oils, food-grade oils, and lubricating greases used in production lines

- Strong alkaline or acidic cleaning agents during sanitation procedures

- Hot steam and high-pressure water from cleaning equipment

If cables lack oil-resistant and chemical-resistant jackets or are not ECOLAB®-certified, they are more likely to:

- Suffer from blistering, cracking, or corrosion of the insulation layer

- Have shortened service life, leading to electrical leakage or short circuits

- Disrupt automation systems, potentially causing unplanned production downtime

5.2 Why is the conduit system important in the F&B industry?

In the F&B industry, conduit systems play a crucial role in protecting electrical and control wiring from harmful factors such as moisture, chemicals, dust, and microorganisms. When electrical cables are exposed directly to high-humidity environments, aggressive cleaning agents, or potential contaminants, they can quickly degrade and cause equipment failure.

With the increasing implementation of automation - especially in conveyor systems, packaging robots, and processing lines - F&B factories often deploy thousands of meters of power and signal cables. These cables require optimal protection using conduit systems to ensure electrical safety, prevent electromagnetic interference (EMI), and extend the lifespan of equipment.

5.3 What technical requirements should conduits meet in F&B environments?

To perform effectively in food and beverage processing facilities, conduits should meet the following criteria:

- Liquid-tight protection: Sealed design with rubber gaskets or secure fittings to prevent moisture ingress

- Chemical and corrosion resistance: Able to withstand industrial cleaning agents and disinfectants

- Robust construction: High impact resistance and the ability to endure mechanical stress

- Smooth surface finish: Easy to clean and resistant to dirt and bacterial buildup

5.4 What is ER rating? Its significance for control cables in the F&B industry

ER stands for "Exposed Run" - a designation that allows control cables to be installed without conduit protection while still maintaining electrical and mechanical safety. When you see markings such as TC-ER, ITC-ER, or PLTC-ER on a cable jacket, it means the cable is UL-certified (Underwriters Laboratories) to be safely used in open or exposed runs for a specific distance without additional protective conduit.

In the F&B industry, ER-rated cables are especially valuable due to several key advantages:

- No conduit required: ER-rated cables can be installed in tight or complex spaces where using conduit is impractical — such as inside automated packaging machines, conveyor systems, or washdown areas. This reduces installation time and labor costs.

- Designed for harsh environments: To qualify for the -ER marking, cables must pass strict impact and crush resistance tests. This includes performance under high-pressure washdowns, chemical exposure, extreme temperatures, and microbial contamination — all of which are common in F&B facilities.

ER-certified cables offer a cost-effective, hygienic, and durable solution for modern F&B manufacturing — delivering electrical safety and compliance without sacrificing efficiency or cleanliness.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |