TOPFLEX® Motor 109: Special power supply cable for frequency converter

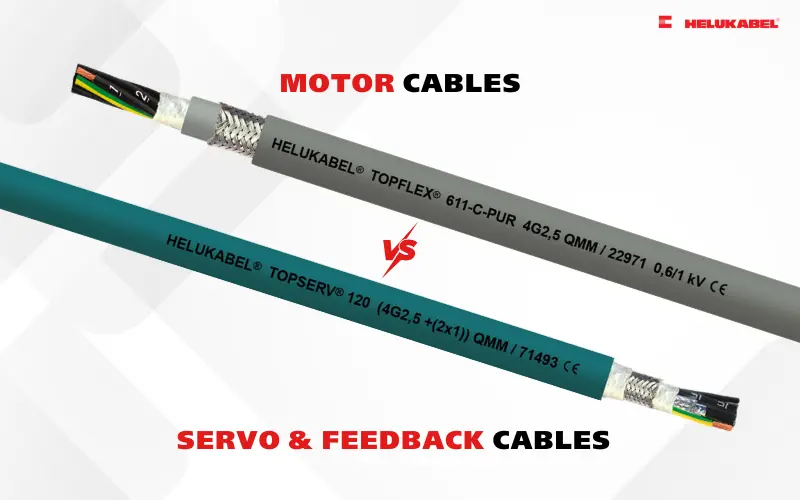

HELUKABEL Vietnam offers a wide range of comprehensive electrical connection solutions. Especially Motor, Servo & Feedback cables with many products. In particular, the TOPFLEX® Motor 109 control cables are designed with anti-interference screens, allowing outdoor applications and many other modern industrial uses.

TOPFLEX® Motor 109 Cables

TOPFLEX® Motor 109 Cables is low capacitance power supply cable 0,6/1kV, increased ampacity, halogen-free, meter marking.

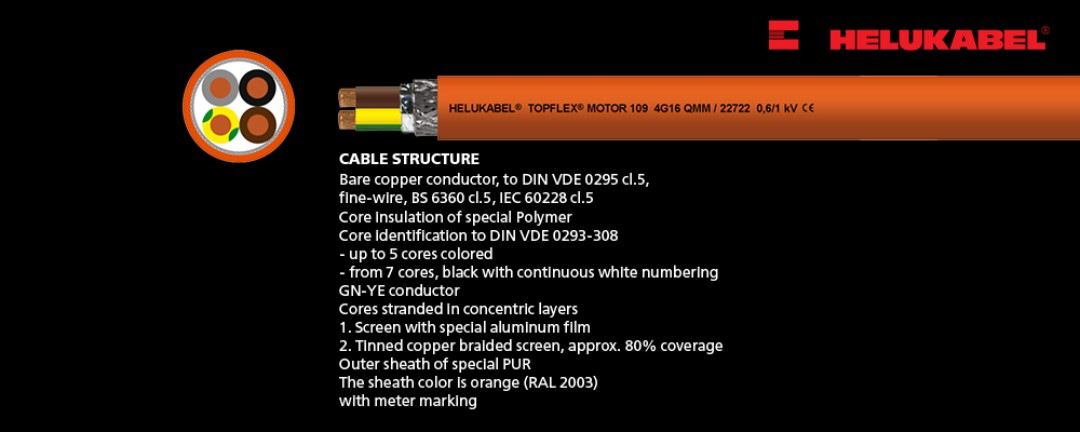

1. Structure of TOPFLEX® Motor 109 cables

- Bare copper conductor, to DIN VDE 0295 cl.5, fine-wire, BS 6360 cl.5, IEC 60228 cl.5

- Core insulation of special Polymer

- Core identification to DIN VDE 0293-308

up to 5 cores colored

from 7 cores, black with continuous white numbering

- GN-YE conductor

- Cores stranded in concentric layers

- Screen with special aluminum film

- Tinned copper braided screen, approx. 80% coverage

- Outer sheath of special PUR

- The sheath color is orange (RAL 2003)

- with meter marking

2. Technical data

- Special motor power supply cable for frequency converters

- Temperature range

flexing -5°C to +70°C

fixed installation -40°C to +80°C

- Permissible operating temperature at conductor +90°C

- Nominal voltage U0/U 600/1000 V

- Max. operating voltage

A.C. and 3-phase 700/1200 V

DC operation 900/1800 V

- Test voltage 2500 V

- Insulation resistance min. 200 MOhm x km

- Coupling resistance

acc. to different cross-sections

max. 250 Ohm/km

- Mutual capacitance

acc. to different cross-sections

core/core 70 to 250 nF/km

core/screen 110 to 410 nF/km

- Minimum bending radius

free-movement for outer Ø:

up to 12 mm: 10x cable Ø

> 12-20 mm: 15x cable Ø

> 20 mm: 20x cable Ø

fixed installation for outer Ø:

up to 12 mm: 5x cable Ø

> 12-20 mm: 7,5x cable Ø

> 20 mm: 10x cable Ø

- Radiation resistance up to 80x106 cJ/kg (up to 80 Mrad)

3. Properties of TOPFLEX® Motor 109

- Special polymer insulation ensures low dielectric losses, dual voltage resistance, longer service life and low - interference shield, and increased current carrying capacity

- Low coupling resistance for high electromagnetic compatibility

- UV-resistant

- Outdoor application

- This screened motor supply cable with the low mutual capacitance of the single cores because of the special Polymer core insulation and low-screen capacitance enable a low-loss transmission of the power compared to PVC-sheathed connecting cables

- Due to the optimal screening, an interference-free operation of frequency converters is obtained

- Design acc. to the requirements of VdS 3501:2006-04

- The materials used in manufacture are cadmium-free and contain no silicone and are free from substances harmful to the wetting properties of lacquers

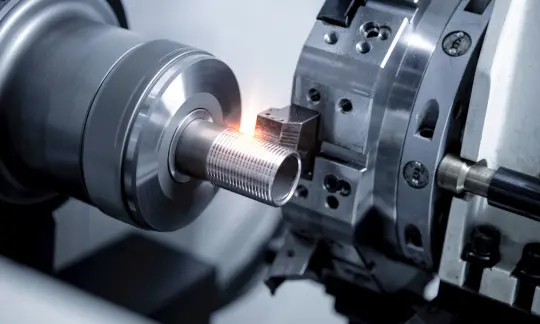

4. Applications of TOPFLEX® Motor 109 cable

The TOPFLEX® Motor 109 control cables provide motor power to the frequency converter , ensuring electromagnetic compatibility in factories and buildings, facilities with operating units, and equipment where fields of Electromagnetic interference may cause adverse effects on the surrounding environment.

It is a supply and connection cable for medium mechanical stresses in fixed installations, forced movements in dry, humid, and wet environments, and outdoor applications. Commonly used in the automotive and food industries, environmental technology, packaging industry, and machine tools. Handling equipment for SIMOVERT actuators, they are particularly suitable for use with industrial pumps, ventilators, conveyors and air conditioning installations, and similar applications.

Electromagnetic compatibility (EMC) screens must be connected at both ends and ensure large area contact across the entire cable circumference to comply with the functional interference requirements of EN 55011. The product is conformed with the EC Low-Voltage Directive 2006/95/EC.

With many experts in the field of electrical connections, we, HELUKABEL have been a companion with many businesses and manufacturing plants in the Vietnam market. For special areas that require cables with their own specifications, we are ready to research and manufacture products to meet customer requirements. If you have any questions or need advice, please contact our engineers for more information.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |