Servo & feedback cables vs motor cables: How to tell them apart?

Both servo & feedback cables and motor cables are used to supply power to motors and have a rated voltage of 600/1000V. But what are the differences between these two types of cables? Let’s explore in the following article.

1. Understanding servo & feedback cables

The cable used to connect a servo drive to a servo motor is called a servo cable

1.1 What are servo & feedback cables?

In the field of electrical engineering, the cable used to connect a servo drive to a servo motor is called a servo cable. This cable serves to transmit both power and control signals from the frequency converter to the motor. Unlike direct power supply, the frequency converter controls the motor speed by adjusting the shape of the voltage waveform.

For this reason, servo & feedback cables are typically rated at 600/1000V and are designed with an overall shielding to protect the signals and minimize electromagnetic interference (EMI) in industrial environments.

In addition to the main power cores, servo & feedback cables also include two additional shielded pairs for connecting temperature sensors or electromagnetic brake systems on the servo motor. This design allows the cable to deliver power while ensuring precise, safe, and stable control of the drive system.

>>Find out more: What are servo motors? Their features and applications

Construction of servo & feedback cables

1.2 Construction of servo & feedback cables

One of the most important aspects of a servo & feedback cable is its shielding. Basically, servo & feedback cables feature two types of shielding:

- Overall shield: This layer surrounds all the cable cores and ensures electromagnetic compatibility (EMC). It prevents the voltage and signals within the cable from interfering with other devices, machine components, or nearby control systems.

- Shield for control pairs: These shielded pairs prevent noise from the power lines from affecting the control circuits, ensuring that the data transmitted to the frequency converter remains accurate and stable.

The design of the shielding varies depending on the mechanical stresses the servo cable must withstand, such as continuous bending, stretching, vibration, or harsh industrial environments. For high-performance applications, the shielding coverage can reach 85–90%, enhancing both EMI protection and mechanical durability.

Additionally, to support high-speed and stable signal transmission, the control pairs are usually twisted using a specialized technique. This not only improves electromagnetic shielding but also allows for faster installation and easier connections.

Thanks to this design, servo & feedback cables not only transmit power but also protect and maintain the precision of control signals, ensuring that servo motors operate reliably in modern automation systems.

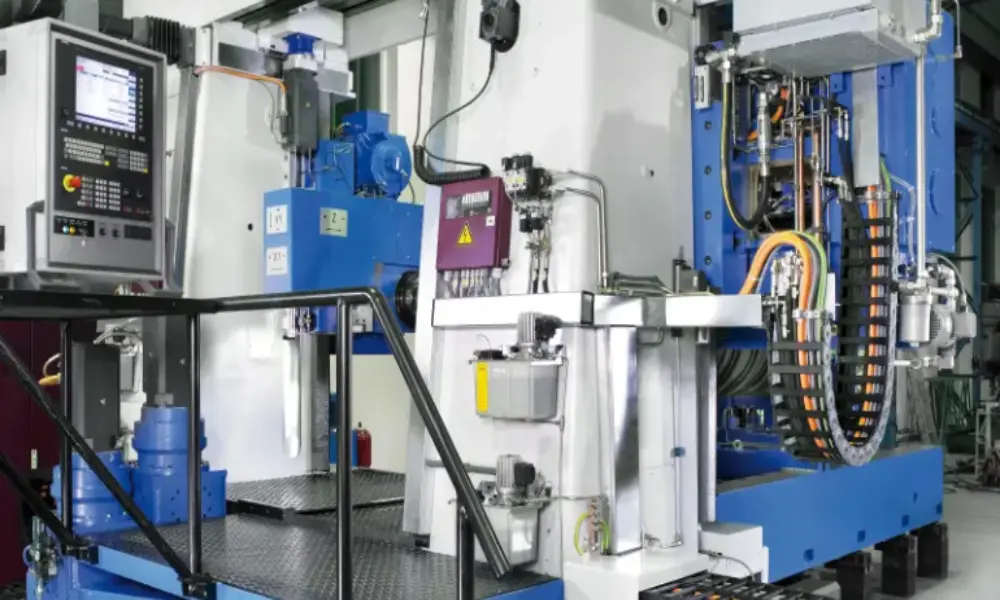

Servo & feedback cables are widely used in many modern industrial applications

1.3 Applications of servo & feedback cables

Thanks to their specialized structure with shielding and control signal cores, servo & feedback cables not only transmit electrical power but also ensure precise and stable control signals. For this reason, they are widely used in many modern industrial applications:

- Machine tools: Used in CNC machines, milling machines, lathes, and grinders with multiple moving axes.

- Industrial robots and automation: Employed in linear robots, pick-and-place robots, welding robots, and assembly robots.

- Packaging and production lines: In packaging, bottling, and labeling machines, servo cables enable precise speed and position control.

- Automotive industry: Applied in car assembly lines, painting systems, and automated welding stations.

- Other industries: Pharmaceutical and food processing, printing and packaging, and energy sectors, among others.

2. Understanding motor cables

To supply power to a three-phase electric motor, a motor cable is used.

2.1 What are motor cables?

To supply power to a three-phase electric motor, a motor cable is used. Typically, this type of cable consists of:

- Three black cores corresponding to the three phases L1, L2, and L3.

- One green-yellow core serving as the Protective Earth (PE), ensuring safety and preventing electrical leakage.

In practice, the stator windings of the motor are usually connected in either a star (Y) or delta (Δ) configuration. This connection method reduces the number of cores needed in the cable to four, making it simpler and more cost-effective.

The outer sheath of a motor cable can be made from various materials such as PVC, PUR, or specialized rubber, depending on requirements for oil resistance, chemical resistance, abrasion resistance, or high-temperature tolerance.

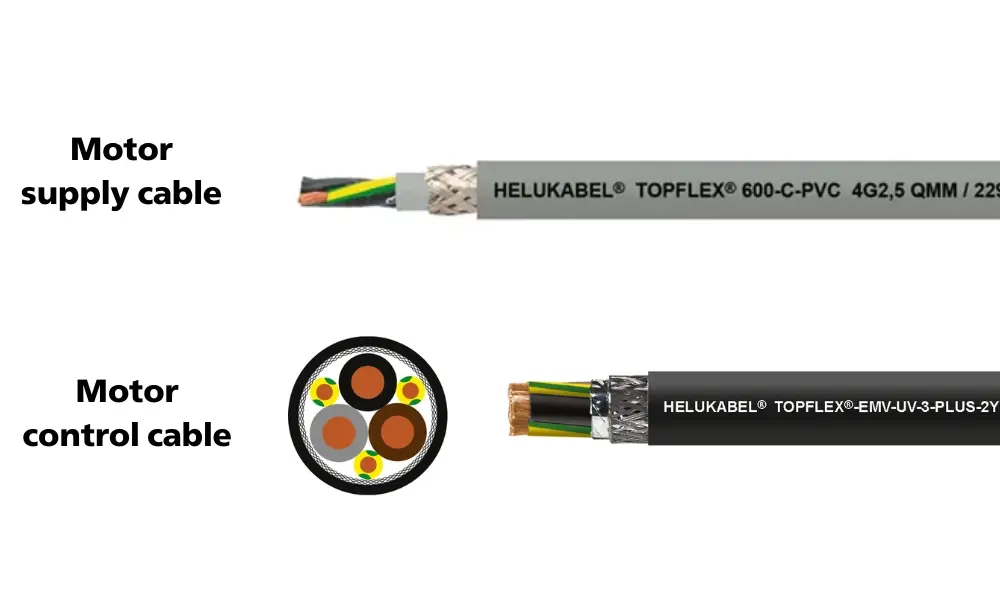

Motor supply vs motor control cables

2.2 Motor supply cables and motor control cables

A motor supply cable is a specialized electrical cable designed specifically to deliver power to motors. These heavy-duty cables are capable of carrying high voltages and currents while withstanding the demanding operating conditions that motors often encounter. The main function of a motor supply cable is to transmit electrical energy from a power source (such as a control cabinet or transformer) directly to the motor. With high reliability, this type of cable ensures stable and continuous power delivery, which is especially important in applications requiring motors to operate continuously, precisely, and efficiently.

In contrast, a motor control cable is responsible for transmitting control signals that direct the operation of the motor according to system requirements. These cables are specially designed to carry the electrical currents needed for motor control while providing mechanical protection and durability for long-term operation.

| Features | Motor supply cables | Motor control cables |

| Features | Transmit electrical power | Transmit control power |

| Voltage | High | Low |

| Flexibility | Low to medium | High, ensuring stable signal transmission |

2.3 Why should we use motor cables for certain applications instead of standard control cables?

When discussing motor power supply cables, many people often think only of the standard four-core power cable. However, in practice, a four-core control cable can also be used in some applications. The key point is that the cable must safely connect the motor to the frequency inverter.

The prerequisite is that the cable insulation must withstand a voltage rating of 600/1000V. This is because the frequency inverter operates on the principle of pulse width modulation (PWM) to control the motor’s speed and frequency. This process generates voltage spikes with amplitudes significantly higher than the normal rated voltage.

If the insulation cannot withstand these voltage spikes, the cable will degrade quickly, potentially causing overheating, insulation damage, or even short circuits and fire.

For this reason, in most industrial applications, motor cables are designed with a higher voltage rating than standard control cables (typically 300/500V) to ensure:

- Safe operation in harsh industrial environments.

- Long service life, even under continuous bending or installation in energy chain systems.

- Electromagnetic interference (EMI) protection, addressing the high-frequency switching characteristics of frequency inverters.

3. Differences between servo & feedback cables and motor cables

In the field of industrial drives, servo & feedback cables and motor cables are often mentioned together, but they have distinct characteristics and applications. Properly distinguishing between these two types of cables helps engineers select the right solution for each system, ensuring operational efficiency and long-term durability.

3.1 Purpose

- Servo & feedback cables: Designed to supply power and transmit control signals to a servo motor. In addition to the main power conductors, servo cables also include shielded control pairs for connecting temperature sensors or brake systems on the motor.

- Motor cables: Used to transmit electrical power from a control cabinet, frequency inverter, or power source to the motor. These are heavy-duty cables, designed to handle high currents and voltages during operation.

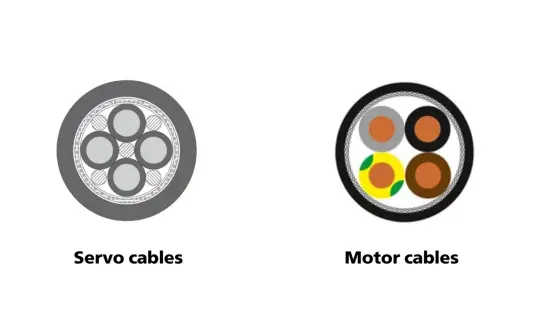

3.2 Construction of servo & feedback vs motor cables

Servo & feedback cables:

- Structure: In addition to the four main cores, servo cables usually include 1–2 shielded control pairs for connecting sensors or brakes.

- Shielding: Always equipped with an overall shield to reduce electromagnetic interference (EMI).

Motor cables:

- Structure: Consists of four main cores (three phase cores + one PE protective earth core).

- Shielding: May or may not have shielding.

- Characteristics: Simple design, sufficient for operating high-power motors.

Typically, servo cables are pastel orange, while motor cables have a black jacket

3.3 Cable color coding according to DESINA standard

One of the most noticeable differences between these two types of cables is their color. Typically, servo cables are pastel orange, while motor cables have a black jacket. This distinction comes from the DESINA standard, which is a mechanical engineering standard aimed at standardizing cable systems.

According to DESINA:

- Motor cables: must have a black outer jacket.

- Servo cables: must have a pastel orange outer jacket (RAL 2003).

DESINA stands for Distributed and Standardized Installation Technology for machine tools and manufacturing systems. It is a set of specifications that standardizes electrical, hydraulic, and pneumatic components, as well as their interconnections on a single platform for CNC-controlled machine tools and production systems.

Since November 2005, after the publication of ISO 23570 Parts 1 and 2 by the International Organization for Standardization (ISO), DESINA installation technology has been recognized as an international standard.

The color coding according to functional codes is as follows:

- Orange (RAL 2003): Servo applications, shielded

- Green (RAL 6018): Measuring systems, shielded

- Violet (RAL 4001): Fieldbus, shielded

- Yellow (RAL 1021): Sensors/actuators, not shielded

- Black (RAL 9005): Outputs, not shielded

- Gray (RAL 7040): 24 V control cables, not shielded

3.4 Practical applications

Servo & feedback cables: Commonly used in CNC machines, industrial robots, and automated production lines, where precise control of position, speed, and feedback signals from the motor is required.

Motor cables: Typically used in drive systems for pumps, fans, compressors, conveyors, or other high-power motors that require stable electrical power transmission.

4. HELUKABEL’s servo & feedback and motor cable portfolio

4.1 Servo & feedback cables

HELUKABEL offers servo & feedbacks cable series made from a variety of materials such as PVC, PUR, and TPE.

We offer various servo & feedback cables adhered to various standards such as UL/CSA, ECOLAB, VDE, UKCA...

| Cables | Features | Part no. |

| TOPSERV® 109 PUR, acc.to Siemens 6FX8008PLUS | · Oil-resistant · Highly resistant to cleaning and disinfecting agents according to ECOLAB® standards · Compliant with DESINA standards | 75943 |

| TOPSERV® 113 PUR, acc.to Siemens 6FX8008PLUS | 78948 | |

| TOPSERV® 113 PUR, acc.to Lenze | 707228 | |

| TOPSERV® 113 PUR | 77376 | |

| TOPSERV® 121 PUR, acc.to Bosch Rexroth | 706003 | |

| TOPSERV® 110 (1 pair screened and overall screening) | Low capacitance thanks to PP insulation on the cores. Compatible with SIMODRIVE systems. | 71491 |

| TOPSERV® 120 (2 pairs individually screened and overall screening) | 71990 | |

| TOPSERV® 108 PVC, acc.to Siemens 6FX5008 | Oil-resistant Compliant with DESINA standards UL AWM Style 2570 / CSA AWM certified | 707250 |

| TOPSERV® 112 PVC, acc.to Siemens 6FX5008 | 707280 | |

| TOPSERV® 112 PVC, acc.to Lenze | 707221 | |

| TOPSERV® 119 PVC, acc.to Bosch Rexroth | 707290 |

TPE sheathed cables from HELUKABEL: TOPSERV 600/650 VFD

4.2 TPE servo & feedback cables

TOPSERV® 600 VFD and TOPSERV® 650 VFD are our special servo cable products. These cables are made from premium TPE material, making them particularly suitable for applications in environments with extreme temperature ranges. Key features of these two products include:

- Stable operation in temperatures from -45°C to +105°C, suitable for both deep-freeze areas and high-temperature environments

- ECOLAB certified, ideal for the F&B industry

- Compliant with UL tray cable standards: UL 1277 and WTTC 2277

- Excellent mechanical properties, meeting UL Exposed Run (ER) standards: TC-ER, PLTC-ER, ITC-ER, allowing direct installation without conduit or protective trays

TC = Tray Cable, ITC = Instrumentation Tray Cable, PLTC = Power-Limited Tray cable

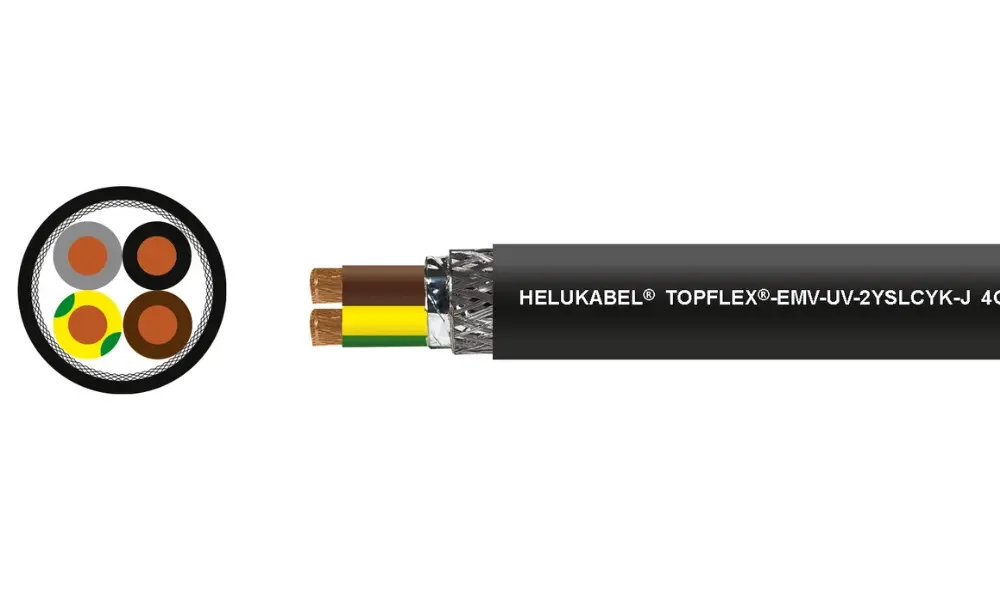

4.3 Motor cables

| Cables | Features | Part no. |

| TOPFLEX®-EMV-UV-2YSLCYK-J | Double screening | 22234 |

| TOPFLEX® 600-C-PVC motor supply cable | Oil-resistant Flame-retardant | 22960 |

| TOPFLEX® 611-PUR motor supply cable | Oil-resistant For servo and DNC motor | 22870 |

| TOPFLEX®-MOTOR-EMV 1/1 | Double screening | 78377 |

| TOPFLEX®-MOTOR-EMV 3/3 | 78614 |

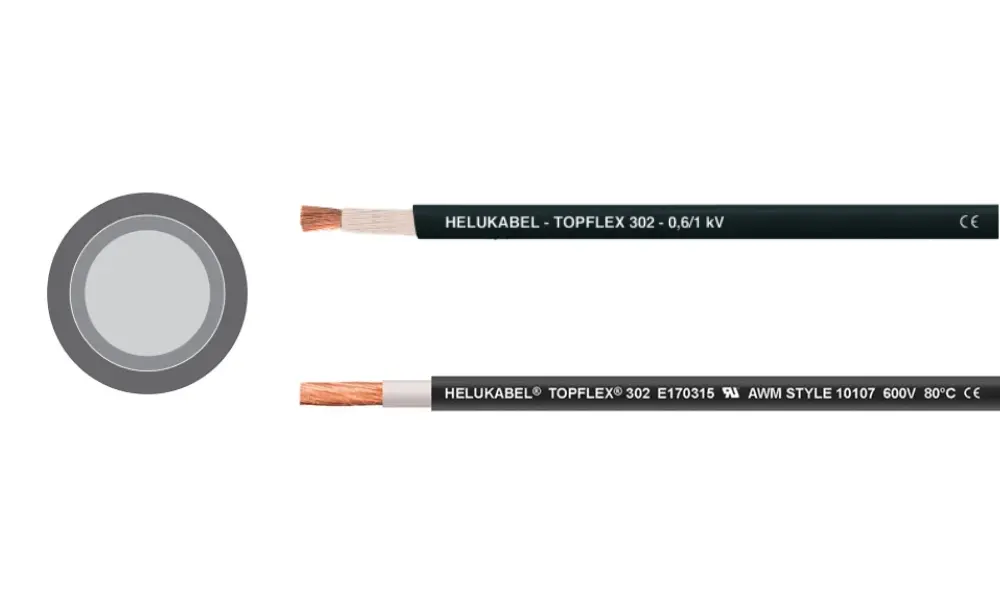

TOPFLEX® 302 / 302-UL single-core motor cables

4.4 Single-core motor cables

In addition to the traditional four-core motor cables, HELUKABEL also offers single-core motor cables for high-power drive systems. This solution provides several advantages:

- Lower cost compared to multi-core alternatives.

- High durability, suitable for tight installation spaces in cable chains, while also offering a longer service life, especially in applications with long travel distances.

The TOPFLEX® 302 / 302-UL motor cables are highly flexible single-core cables, featuring double-layer PVC insulation and excellent low-temperature flexibility. The 302-UL version is UL Approval certified (Style 10107).

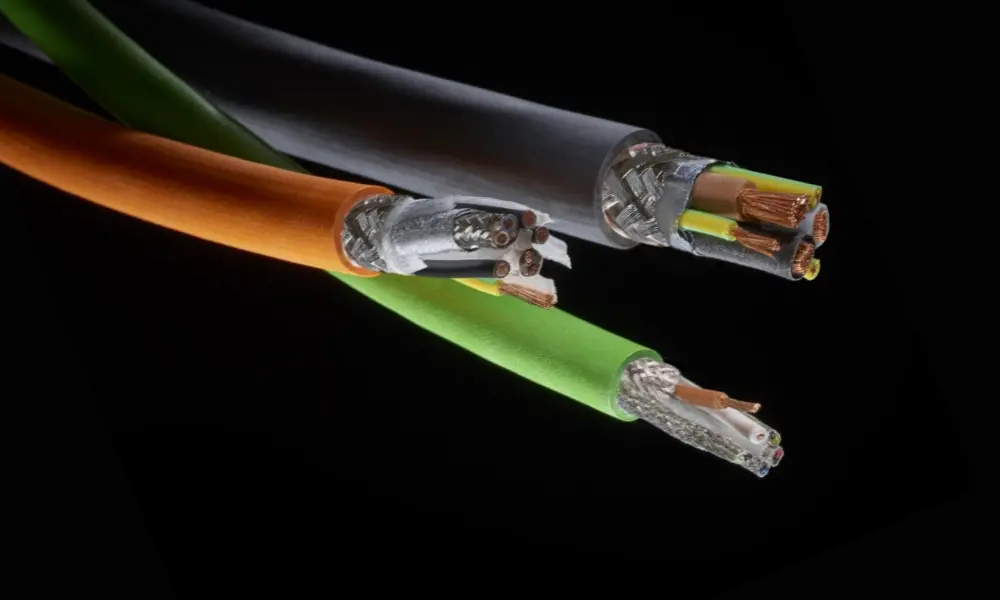

Hybrid servo motor cable

4.5 Hybrid servo motor cables

Hybrid cables are transforming the design of automation systems, especially in servo motor applications. Instead of using separate motor and feedback cables (encoder or resolver), hybrid cables integrate both functions into a single solution.

Using hybrid cables offers several clear advantages:

- Space efficiency: Frees up space inside the cable carrier and at the motor connection area.

- Cost savings: One cable replaces two, significantly reducing material and accessory costs.

- Enhanced reliability: Fewer connectors mean fewer potential failure points, improving system durability and stability.

HELUKABEL’s hybrid servo motor cable products are available in two versions:

- TOPSERV® Hybrid PVC : Suitable for fixed installations or applications with infrequent movement.

- TOPSERV® Hybrid PUR : Highly flexible, designed for drag chain applications.

5. FAQs about servo & feedback and motor cables

5.1 Can a motor cable be used instead of a servo cable?

In principle, a motor cable can be used to connect a servo motor, but only in certain cases. Motor cables are primarily designed to transmit power, whereas servo cables include additional cores for temperature sensors, brakes, or control signals.

If the servo motor does not require these connections, or if these connections are handled separately via a control cable, using a motor cable as a replacement is possible.

However, for applications that require high precision, strong EMI resistance, and full feedback signal integration, a dedicated servo cable remains the optimal choice to ensure system performance and longevity.

5.2 Can motor or servo cables be replaced by hybrid cables?

Whether motor or servo cables can be replaced by hybrid cables depends on the specific drive system. Some manufacturers already support hybrid solutions or designs that operate with only two cables.

However, many other systems still require separate cables for power and signals. In such cases, hybrid cables cannot be directly used as a replacement.

5.3 What are servo motor assemblies?

Servo motor assemblies (servo and motor cable assemblies) are critical components that ensure precise control and reliable signal transmission across various industries. These assemblies consist of wires, connectors, and shielding mechanisms that are carefully designed to reliably transmit power and signals between servo motors and control systems.

In fields such as industrial automation, aerospace, defense, and medical equipment, servo motor assemblies play a key role in achieving accurate motion, consistent performance, and high productivity.

We HELUKABEL provide customized servo motor assembly solutions tailored to specific requirements.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |