Understanding cable markings and datasheet specifications

In the field of electrical and electronic engineering, selecting the right type of cable not only affects operational efficiency but also directly impacts the safety of the entire system. Therefore, understanding the technical specifications printed on the cable and those provided in the manufacturer’s datasheet is an essential step for engineers, electricians, and businesses that use cables.

1. The role of markings on electrical cables

Cable markings in the cable manufacturing process

Electrical safety is always a top priority in industrial, commercial, and residential environments. Correctly identifying the type of cable plays a critical role in ensuring safety, regulatory compliance, and preventing electrical hazards. Cable markings help engineers, electricians, and maintenance teams manage wiring systems more efficiently while minimizing the risk of accidents.

If cables are not properly identified, they can lead to confusion, mistakes, and potential dangers.

- Preventing electrical hazards: Unmarked cables may result in short circuits, fires, or electric shocks. Clear markings indicate voltage rating, function, and potential risks, thereby reducing hazards.

- Ensuring regulatory compliance: Authorities such as OSHA, IEC, and ISO require proper cable markings to guarantee workplace safety.

- Supporting maintenance and troubleshooting: Cable identification enables quicker inspection, maintenance, and fault resolution, reducing production downtime.

- Improving work efficiency: A well-marked cabling system allows engineers, electricians, and maintenance staff to work accurately without guesswork, ensuring smooth electrical system management. This is especially vital in data centers where hundreds or even thousands of cables are installed.

- Reducing accidents and downtime: Clear identification prevents incorrect connections, equipment failures, and operational issues, contributing to a safer and more reliable working environment.

2. Cable markings and datasheets

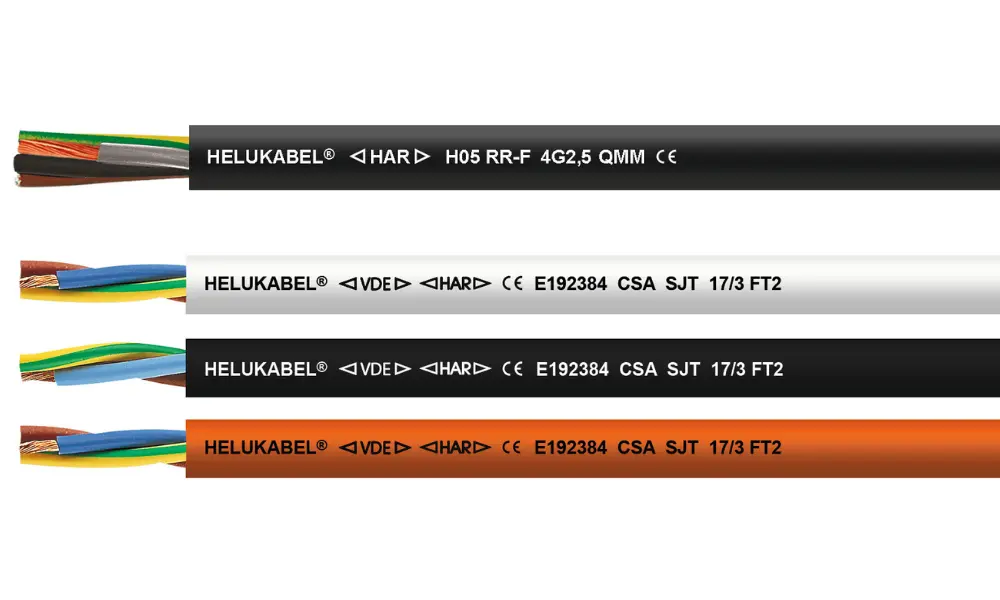

Markings and specs printed on cables

Although these two types of information appear in different formats, they complement each other, helping engineers, contractors, and end users select, install, and operate electrical systems more accurately.

2.1 Markings and specs printed on cables

On the outer sheath of cable, manufacturers print basic markings and electrical specifications that allow users to identify and understand the essential information about the cable. This information helps users determine the fundamental characteristics of the cable, regardless of the manufacturer.

Typical markings include:

- Product name or code: e.g., H05V-K, H07RN-F, JZ-500

- Number of cores and cross-section: e.g., 3G2.5 mm² (3 cores, with grounding conductor, 2.5 mm² cross-sectional area)

- Nominal voltage: 300/500 V, 0.6/1 kV

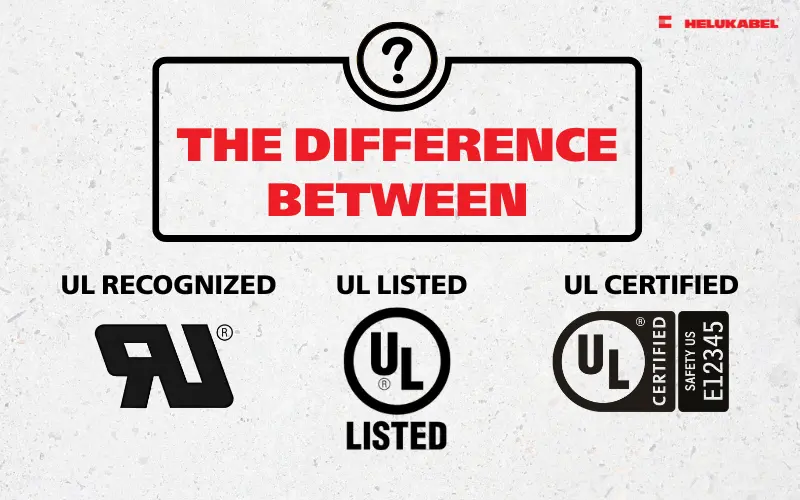

- Applicable standards: IEC, UL, CSA, VDE...

- Additional information: flame-retardant (FR), low smoke zero halogen (LSZH), oil-resistant (OIL RESISTANT) …

Advantages: easy to identify, convenient on-site, no additional documents required.

Limitations: only provides general information, insufficient for detailed calculations.

Datasheets provided by cable manufacturer

2.2 Datasheet provided by cable manufacturers

A datasheet provided by the manufacturer is a detailed document that helps users understand the full characteristics of a specific electrical cable. Not all datasheets are the same. The way information is presented and structured often varies depending on the manufacturer and the specific cable type.

The main groups of information in a datasheet typically include:

- Electrical specifications: operating temperature range, voltage ratings (test voltage, nominal voltage, breakdown voltage), bending radius…

- Cable construction details: conductor material (copper or aluminum), insulation and sheath materials, presence of shielding or armoring…

- Cable properties: mechanical characteristics (tensile strength, abrasion resistance), flame-retardant or fire-resistant performance…

- Application scope: whether suitable for fixed installation, cable trays, direct burial, or specific industrial applications.

- Compliance standards: a particularly important section, indicating whether the product meets relevant regulations and whether it is permitted for installation in specific systems.

3. How to read cable markings on HELUKABEL products

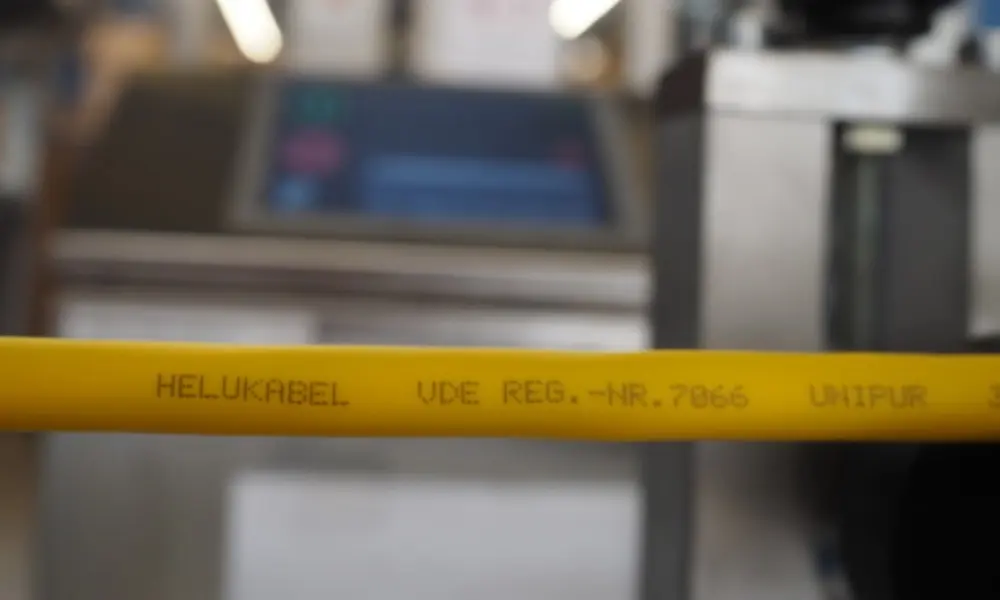

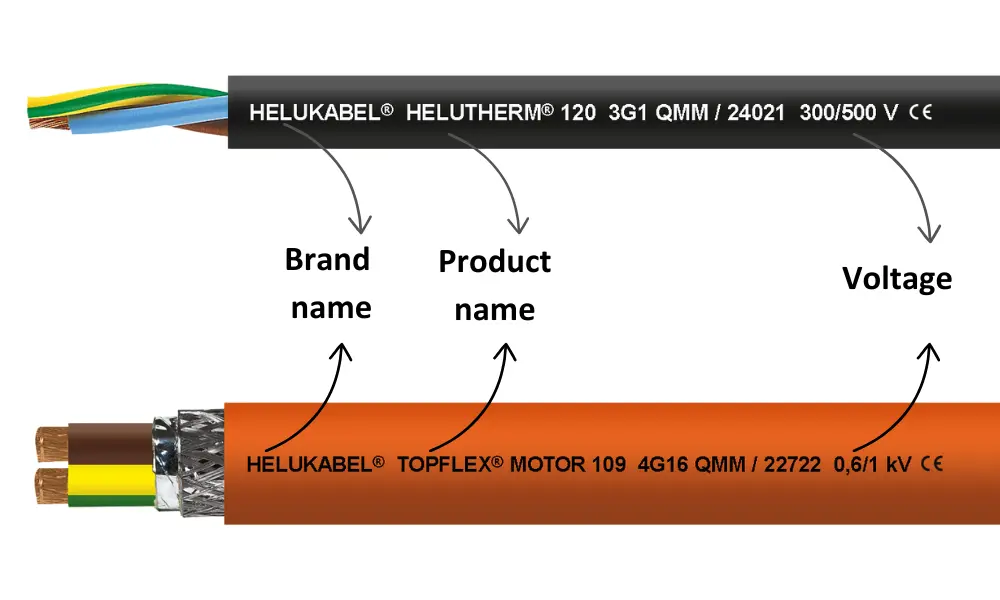

Manufacturer, product line, and voltage information on HELUKABEL cables

3.1 Manufacturer and product line information

On the outer sheath of a cable, the first markings usually indicate the manufacturer or product line. The purpose of this information is to help users quickly identify which company produced the cable and to which product family it belongs. Each product line name is often associated with a specific set of features such as heat resistance, flame retardance, or oil resistance.

For example, HELUKABEL product lines include:

- BIOFLEX-500®: Oil-resistant cables suitable for industrial environments with exposure to biological oils and lubricants.

- DATAFLAM®, DATAPUR-C®: Data and computer cables with flame-retardant or halogen-free properties.

- HELUFLON®, HELUTHERM®, THERMOFLEX®: Heat-resistant cables designed for high-temperature applications.

- HELUTRAIN®, HELUTRUCK®, HELUWIND®: Specialized cables for railway, truck, and wind energy applications.

- ROBOFLEX®, NANOFLEX®, SUPERTRONIC®: Cables for robotic systems and drag chains, ensuring flexibility and high mechanical durability.

- SOLARFLEX®: Photovoltaic (PV) cables for solar energy systems.

- TOPFLEX® / TOPSERV®: Servo, feedback, and motor cables.

- DNB cables with HELUCOM® (fiber optic) and HELUKAT® (copper data cables)

3.2 Voltage markings

The voltage rating of a cable is the basis for determining its construction as well as the required electrical performance tests. According to DIN VDE 0298 and IEC 183, cables are designated with the marking U₀/U, where:

- U₀ = Nominal voltage between the conductor and the outer metallic shield or earth (ground).

- U = Nominal voltage between phase conductors. For three-phase systems: U = × U₀.

Common voltage ratings printed on electrical cables include: 300/500 V, 450/750 V, 0.6/1 kV

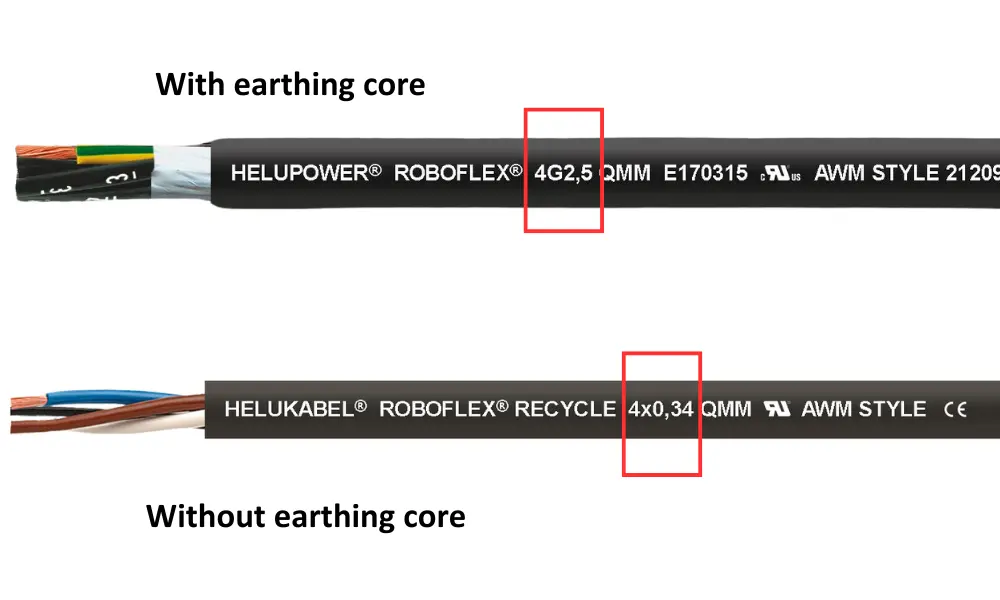

Designation for cables with or without earth core

3.3 Number of core and conductor cross-section

This information is printed with the format: Number of cores + G/X + Cross-section.

- Number of cores: Indicates how many conductors are inside the cable, e.g., 3-core, 4-core, or 5-core. One of the cores may be a neutral or an earth (ground) conductor.

- Earth core designation:

G: Cable with an earth (ground) conductor. Example: 4G2.5 means a cable with 4 cores, one of which is an earth conductor, with each conductor having a cross-section of 2.5 mm².

X: Cable without an earth (ground) conductor. Example: 4X2.5 means a cable with 4 conductors (no earth conductor), each with a cross-section of 2.5 mm².

- Nominal cross-section (in mm²): Expressed in square millimeters (mm²), this value represents the current-carrying capacity of the conductor. The larger the cross-sectional area, the higher the amount of current the cable can carry, and vice versa.

- AWG marking: On some cables, the sheath may also display AWG (American Wire Gauge). This is a U.S. standard for wire thickness. In principle, the higher the AWG number, the smaller the conductor diameter.

>>Technical article: A glance at AWG and their implications

Cable length (meter marking)

3.4 Cable length marking

In addition to markings for cable type, conductor cross-section, or technical standards, the outer sheath of cables often includes meter marking. This refers to sequential length numbers printed along the sheath that indicate either the remaining length on the reel or the length already pulled.

For example, the sheath may display “50m – 49m – 48m …” in descending order, allowing users to quickly check how many meters of cable have been used and how much is left on the reel.

Although meter marking may seem like a small detail, it provides significant benefits for cable management, installation, and inventory control - particularly in large-scale industrial and commercial projects.

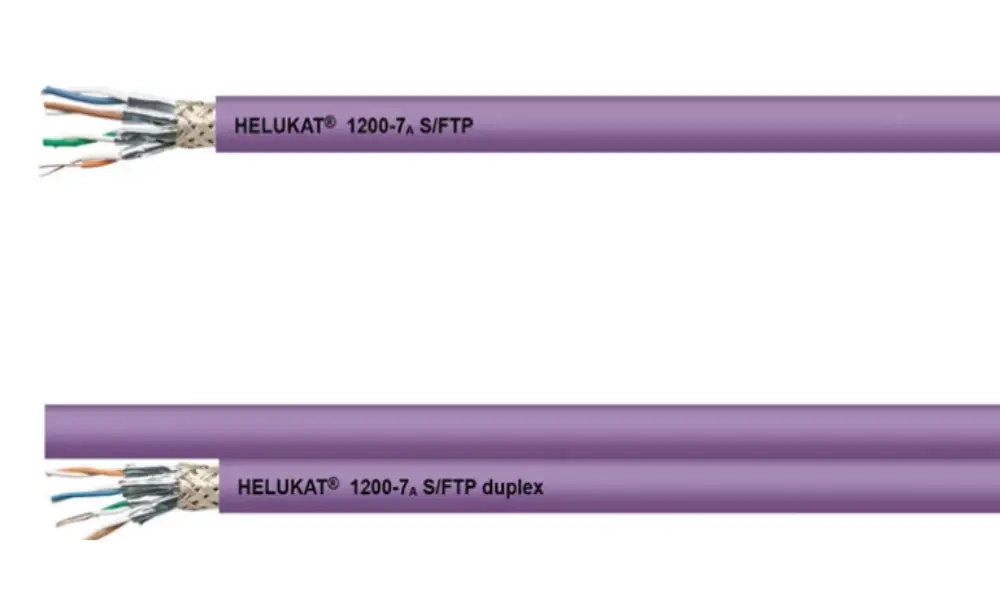

HELUKAT® 1200 CAT.7A S/FTP LSZH STATIC

3.5 Shielding markings on ethernet cables

For LAN (Ethernet) cables, the outer sheath typically displays shielding structure codes such as F/UTP, U/FTP, S/UTP, SF/UTP, F/FTP, S/FTP, and SF/FTP. Each code indicates the type of shielding applied:

- U (Unshielded): Indicates an unshielded cable with no additional protective layer.

- S (Screened/Shielded): Refers to a braided shield around the conductors to reduce electromagnetic interference (EMI).

- F (Foiled): Represents a thin metallic foil wrapped around the cable or conductor groups, providing enhanced shielding against external interference.

- TP (Twisted Pair): Indicates the use of twisted conductor pairs, which naturally reduce crosstalk and ensure stable data transmission.

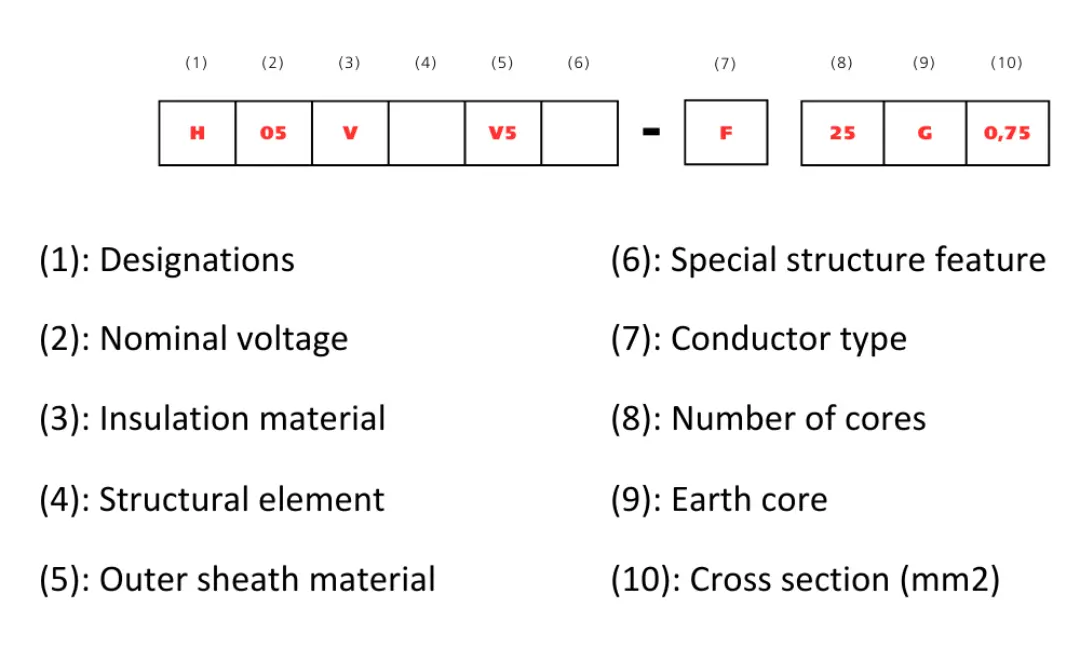

4. How to read harmonized cable markings (HAR cables)

HAR marking on the outer sheath of cable

Harmonized European standard cables, often called HAR cables, were developed by CENELEC (European Committee for Electrotechnical Standardization) to unify cable classification across Europe. This system standardizes cable markings, making it easier for users to identify and select the right cable for their applications.

4.1 Standardization convention

- H: Cable manufactured according to harmonized standards.

- A: Cable manufactured according to national standards (non-harmonized).

4.2 Rated voltage codes

- 01: 100/100 V

- 03: 300/300 V

- 05: 300/500 V

- 07: 450/750 V

4.3 Insulation material

- V (PVC): Polyvinyl chloride

- V2, V3, V4, V5: Modified PVC (heat resistant, cold resistant, oil resistant, cross-linked)

- R (EPR): Ethylene Propylene Rubber

- S (SiR): Silicone Rubber

- Z (PE): Cross-linked Polyethylene

4.4 Special structural features

- C4: Copper braid around conductors

- T, T6: Textile braid around cores or individual wires

- H, H2, H6, H7, H8: Flat cable, multi-layer flat cable, spring cable

- FM: Integrated telecommunication core within power cable

- D3, D5: Strength elements or central core

4.5 Sheath material codes

- V, V2, V3, V4, V5: PVC (standard, heat resistant, cold resistant, cross-linked, oil resistant)

- N, N2, N4 (CR): Chloroprene Rubber (standard, welding, heat resistant)

- Q (PUR): Polyurethane – abrasion resistant, durable

- B (EPR): Ethylene Propylene Rubber

- T, T2: Textile braid (standard or flame-retardant)

4.6 Conductor types

- U: Solid conductor (Class 1)

- R: Stranded conductor (Class 2)

- F, H, K: Fine-stranded conductor, for fixed or flexible installation

- D, E: Extra-fine stranded conductor, often for welding cables

- Y: Tinsel wire (DIN 47104)

4.7 Number of cores and earth conductor

- G: Cable with earth core

- X: Cable without earth core

Additionally, the marking shows the number of cores and the nominal cross-section (mm²).

4.8 HAR-approved cables from HELUKABEL

| Type | Name | Part no. |

| HAR-approved rubber cables | H07RN-F; H05RN-F HELUPOWER® H07RN-F LS0H H05RR-F; H07ZZ-F | 37001; 36001 30737 35001; 37176 |

| HAR-approved PVC cables | H05VV-F / 05VV-F H05VV5-F H03VV-F / 03VV-F H05VVC4V5-K H05VV-F/SJT JZ-603 / OZ-603 JZ-603-CY / OZ-603-CY | 29450 13122 29736 13951 28034 83704 83709 |

| Arc welding cable | H01N2-D H01N2-E | 31001 31032 |

| HAR-approved single core cables | H05V-U H07V-R; H07V-U H07V-K / 07V-K FIVENORM H05V2-K / 05V2-K FIVENORM H07V2-K / 07V2-K / H07V-K / 07V-K | 28761 28825; 28785 29129 64075 64123 |

| HAR-approved PUR, halogen-free cables | H07BQ-F / 07BQ-F H05BQ-F H05Z1Z1-F | 22058 22050 30270 |

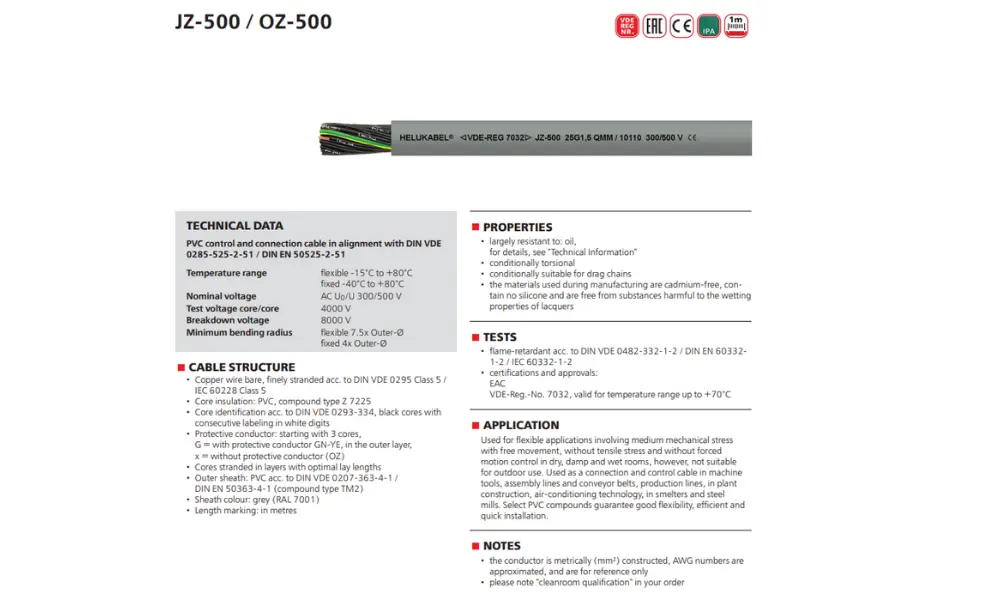

5. How to read cable datasheets from HELUKABEL?

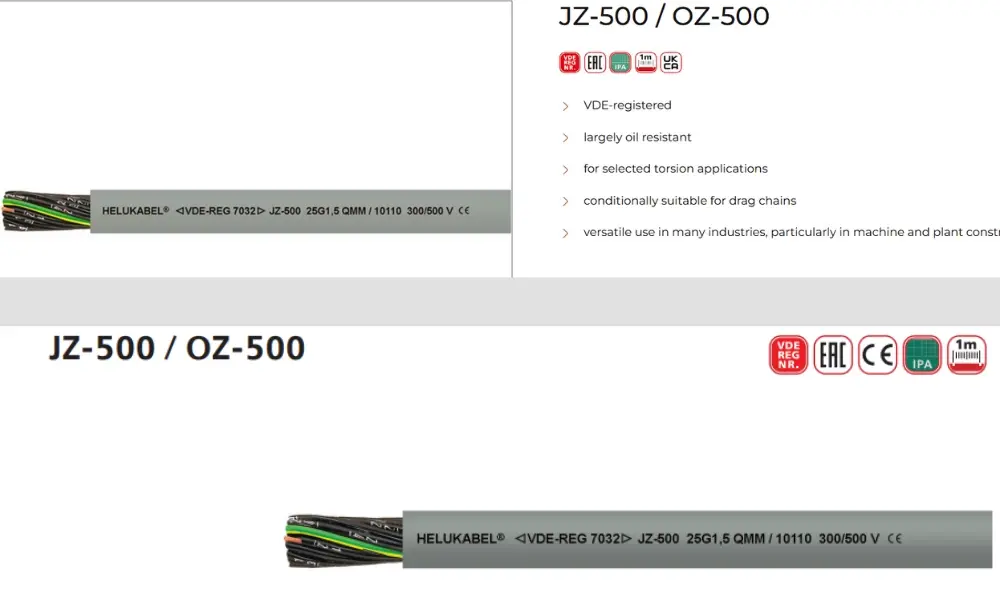

General product information can be found via Product finder or specific product datasheet

Each HELUKABEL product datasheet provides detailed technical information to help engineers, installers, and end users choose the right cable for their application. The datasheet is usually divided into structured sections for easy navigation.

5.1 General product information

At the top of the datasheet, you will always find an overview of the product, including:

- Product name: JZ-500

- Certifications and standards: such as VDE, EAC, IPA, UKCA, or meter marking symbols

- Key product features: for example, oil resistance, suitability for limited torsional movement, or compatibility with drag chain applications

- Product images: many datasheets include a photo of the cable and sometimes a cross-sectional diagram, giving users a clear visual understanding of the cable’s structure and design

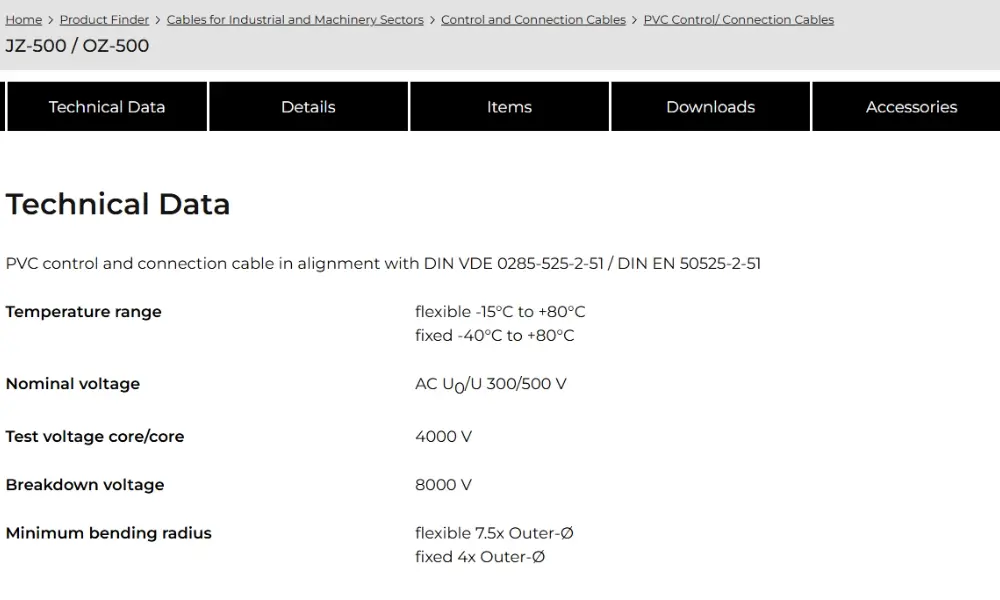

Technical data of our products

5.2 Technical product information

This section provides the key technical specifications that must be followed to ensure reliable performance and safe operation of the system. For example, with the JZ-500 cable, the datasheet specifies:

- Manufacturing standard: JZ-500 is a PVC-sheathed control cable manufactured according to DIN VDE 0285-525-2-51 / DIN EN 50525-2-51.

- Operating temperature range: defined separately for fixed installation and flexible applications.

- Rated voltage: electrical parameters for safe operation under specified conditions.

- Minimum bending radius: a critical factor during installation. Failure to comply with the recommended bending radius may cause conductor breakage, shorten cable lifespan, or damage the insulation.

5.3 Product details

In the Details section of the datasheet, HELUKABEL provides more in-depth information regarding the cable’s construction, properties, testing, certifications, and applications. This information helps users better understand the technical characteristics of the cable and select the right type for their specific requirements.

- Cable construction: Describes each component of the cable, including conductor material, insulation, shielding (if any), and outer sheath.

- Cable properties: Defines the operational characteristics, such as resistance to oil, temperature range, flexibility, or flame resistance. This allows comparison between cables with similar electrical parameters but different material properties.

- Testing and certifications: Lists the relevant standards and approvals, such as IEC flame tests, UL certification, or TÜV water-resistance compliance.

- Applications: Translates technical specifications into practical use cases, indicating suitable operating environments and industries where the cable can be applied.

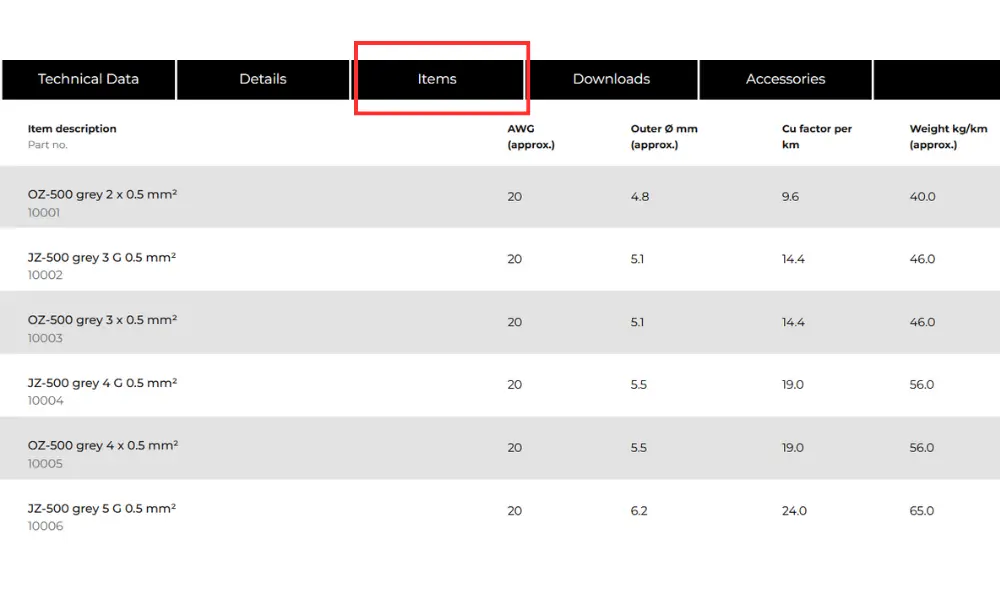

Cable variants in the same product line

5.4 Cable variants in the same product line

The Items section of the datasheet presents a detailed table of all available variants within the same product family. This section enables users to quickly identify and compare technical options:

- Variants within the product line: Each cable type typically comes in multiple versions based on the number of cores, conductor cross-sections, and whether an earth conductor (G) is included or not (X).

- Dimensions and weight: Specifies the outer diameter (Ø mm) for installation planning in conduits, trays, or cabinets, as well as cable weight (kg/km) and copper content (Cu factor per km) for logistics, transport, and cost estimation.

- Part number identification: Provides the exact Part No., which is critical for accurate ordering. Instead of describing the cable as “3 x 0.5 mm²,” users can simply provide the part number to avoid confusion between similar variants.

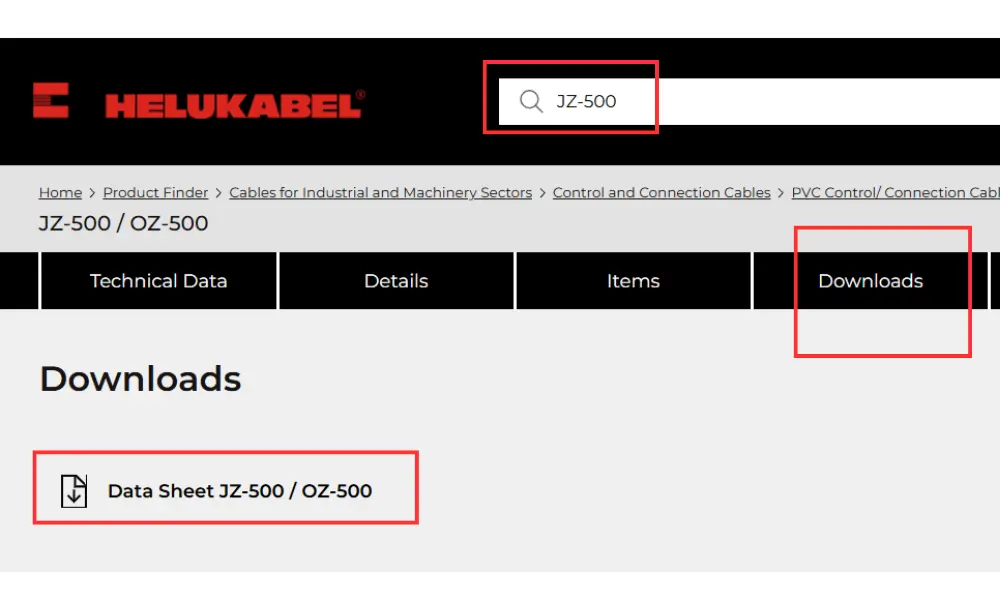

6. How to access HELUKABEL product datasheets?

How to access HELUKABEL product datasheets

To find the datasheet and view the cable markings printed on HELUKABEL products, users can follow one of the two methods below:

Method 1: Using the HELUKABEL Vietnam Product Finder

- Go to the Product Finder page: https://shop.helukabel.com/vn-en

- Enter the product name or Part Number in the search box and press Enter.

- Navigate to the “Downloads” section and download the product datasheet.

Method 2: Direct access via datasheet URL

You can access the latest version of a product datasheet directly using the following URL format: www.helukabel.com/XXXXXen

Note: Replace XXXXX with the specific Part Number of the product.

For example: Part No. 10001 for JZ-500 cable, Part No. 20139 for TRONIC-CY (LiY-CY) cable

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |