What are fire-resistant cables and their applications?

Fire-resistant cables are used with a view to mitigate the risk of fire and explosion. Let’s delve into this topic through the following article.

1. What are fire-resistant cables?

Fire-resistant cables are a specific type of electrical cable engineered to maintain functionality during a fire for a designated duration. They serve to supply electrical power to critical equipment such as smoke extractors, water pumps, and alarm systems in emergency situations.

These cables find extensive application in essential circuits within environments such as hospitals, airports, tunnels, subways, offices, manufacturing plants, and laboratories. Designed to sustain normal operation in temperatures up to 300 degrees Celsius, yet they can only sustain this functionality for a limited period beyond this threshold. The cable's sheath is constructed from non-flammable materials, producing minimal smoke and devoid of halogen, thereby reducing the emission of toxic gases during fire condition.

>>See more: Comparing fire-resistant cables and flame-retardant cables

2. When should we use fire-resistant cables?

Under fire conditions, standard cables might not be capable of withstanding high-temperature, melt, and cause short circuits. This can result in several serious consequences:

- Loss of critical systems: Fire alarm systems, emergency lighting, communication systems, and life support equipment may be damaged, impeding evacuation and response efforts.

- Spread of fire: Burning electrical cables can exacerbate the situation, expanding the fire's scope, increasing heat intensity, and severity of the fire.

- Toxic smoke: Some materials composing electrical cables emit harmful toxins when burned, posing significant health risks to humans.

As a result, in most circumstances, fire-resistant cables play a vital role in maintaining the integrity of the electrical system. They are commonly used in:

- Emergency systems: Fire alarm systems, emergency lighting, public address systems, and elevator control systems rely on these cables to function normally during evacuation.

- Critical infrastructure: Hospitals, data centers, airports, and transportation hubs require uninterrupted power and communication, making fire-resistant cables more essential than ever.

- Hazardous environments: Oil drilling platforms, chemical plants, and other high-risk areas require cables capable of withstanding extreme temperatures and harsh environmental conditions.

3. Structure and feature of fire-resistant cables

Similar to other electrical cables, fire-resistant cables can be either single-core or multi-core cables. Insulating materials may include elastic materials (XLPE, EPR, SiR, or LSOH) rather than thermoplastic materials (EVA, PE, or PVC) to meet stringent requirements for high-temperature environments. Some characteristics regarding the construction of fire-resistant cables include:

Conductor

Due to aluminum conductors' inability to withstand high temperatures, fire-resistant cables utilize solid round copper conductors, tightly stranded. Solid round copper conductors offer several advantages over fan-shaped conductors: When combined with mica tape, the integration of mica and conductors is tightly bound, beneficial for even distribution of electrical systems and enhancing the insulation performance of the electrical cables. Furthermore, with a melting temperature of 1085°C, copper is not only an excellent electrical conductor but also ensures heat resistance.

Sheathed fire-resistant

The fire-resistant layer is the first line of defense of a fire-resistant cable and is typically made of materials with high heat resistance, most commonly mica. Outside the conductor core, there are usually 2 or more layers of mica tape wound around, with a cross-over ratio usually not less than 30%. The width, thickness, and coverage ratio of the mica layer must be accurately ensured during the manufacturing process to prevent leakage and breakage.

Insulating sheath

The insulating sheath is the next line of defense after the fire-resistant layer. The insulating sheath is made of cross-linked polyethylene. This material also protects cables from burning and ensures their long-term operation.

Outer sheath

The heat resistance of fire-resistant cables depends on the permissible temperature of the conductor and the outer sheath. The outer sheath of fire-resistant cables is prone to significant oxidation when being exposed to air. The higher the temperature, the more severe the oxidation process becomes. When the temperature exceeds 250°C, intense oxidation occurs, forming a layer of CuO oxide. This oxide can be toxic if inhaled or contacted by humans. Therefore, the outer sheath is often made of LSHF (Low Smoke Halogen Free) materials, which do not emit toxic smoke when burned.

>>Find out more: Typical types of electric cables

4. Classification of fire-resistant cables

| Basic | Standard | Special | |

| Abbreviation structure | Cu/Mica/XLPE/FR-PVC | Cu/Mica/XLPE/LSHF | Cu/Silicone Rubber mix/LSHF |

| Conductor | Cu | Cu | Cu |

| Sheathed fire-resistant | Mica | Mica | Silicone Rubber mix |

| Insulation | XLPE | XLPE | Silicone Rubber mix |

| Outer sheath | FR-PVC | LSHF | LSHF |

Cu/Mica/XLPE/FR-PVC fire-resistant cables have sheathed fire-resistant layer made from PVC. This is a common material used for insulation sheath. The outstanding features of PVC material are high availability, low cost, and high durability. However, when operating in high-temperature environments for extended periods, the PVC sheath exhibits certain drawbacks. For instance, the PVC sheath may burn under prolonged heat exposure, emitting harmful smoke and gases. Therefore, this type of fire-resistant cable is compatible with indoor environments without high temperatures.

LSHF (or LSZH) outer sheath overcomes the limitations of PVC sheath. Thus, Cu/Mica/XLPE/LSHF fire-resistant cables contain little or no Chlorine, enhancing the cable's durability and heat resistance, as well as providing excellent water resistance. Furthermore, LSHF material does not emit toxic smoke when burned due to its halogen-free nature, ensuring safety for users.

Silicone sheathed fire-resistant cables are developed for use in environments with extreme temperature fluctuations. Silicone material can be used at temperatures as low as -60°C. They are also applied in industries such as steel manufacturing, aerospace, shipbuilding, as well as in ceramic, glass, and cement plants.

>>See more: Comparing PVC sheath and LSZH sheath

5. HELUKABEL’s fire-resistant cables

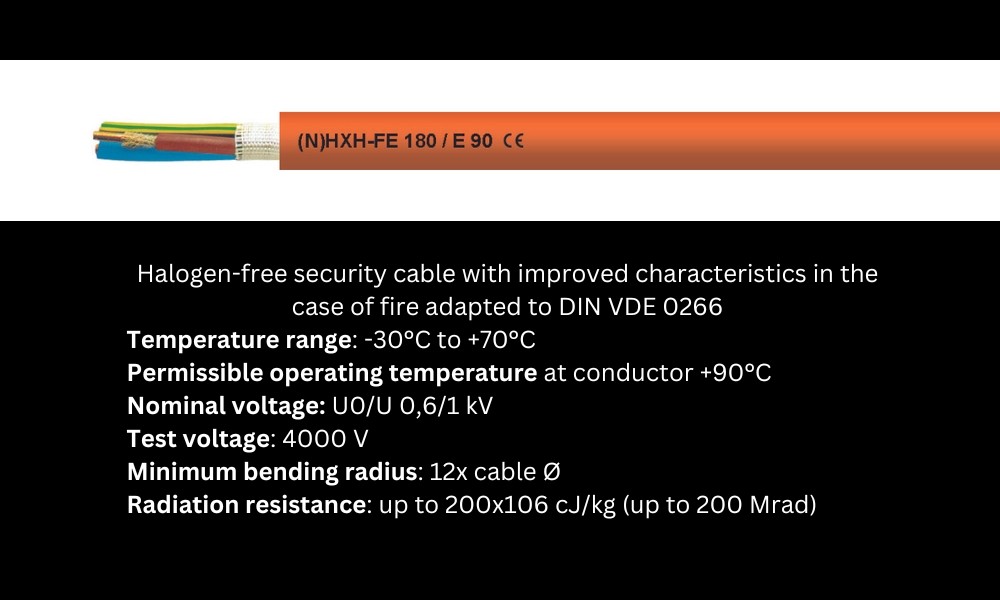

5.1 (N)HXH-FE 180/E 90 control cable

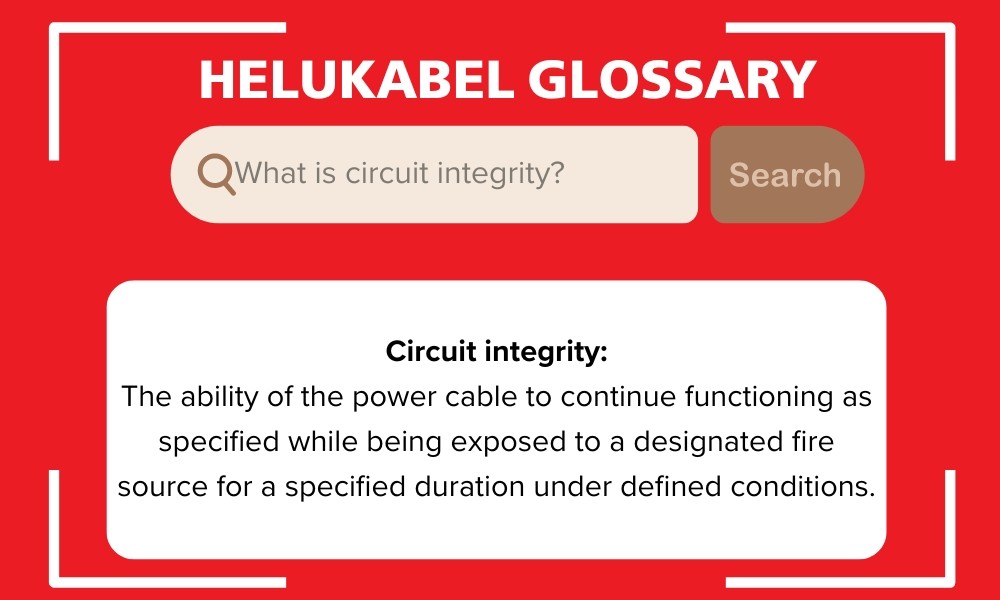

(N)HXH-FE 180/E 90 is a type of control fire-resistant cable, halogen-free with the circuit integrity rating of E90 and limits on material integrity and heat resistance (insulation integrity) of FE180. The symbol E90 indicates that this type of cable can maintain the circuit integrity for equipment and machinery for at least 90 minutes.

This is the type of cable used for indoor installation, outdoor projects, industrial sites, emergency power supply systems, and alarms... places requiring high safety standards to protect people from fires.

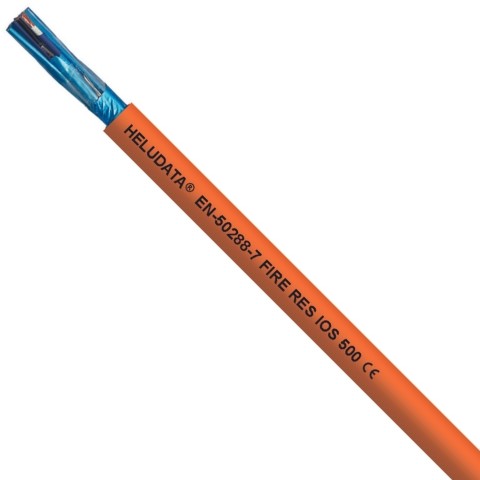

5.2 HELUDATA® EN-50288-7 FIRE RES OSA 500 and HELUDATA® EN-50288-7 FIRE RES IOS 500

These are two lines of fire-resistant cables capable of maintaining stable operation for at least 180 minutes in the event of a fire. Some characteristics of these two cable lines include:

- Compliance with the fire resistance standard IEC 60331-21.

- Low transmission loss and low mutual capacitance, making them suitable for long-distance electrical transmission.

- Cable elements have to be produced out of non-hygroscopic materials.

- Resistant to hydrocarbons.

With these characteristics, both lines of fire-resistant signal cables are used in demanding environments such as the oil, gas, and chemical industries. Both cable lines are suitable for installation in dry or wet areas, open spaces, and underground networks.

Data sheet of HELUDATA® EN-50288-7 FIRE RES OSA 500

Data sheet of HELUDATA® EN-50288-7 FIRE RES IOS 500

5.3 NHXMH-J / NHXMH-O

This cable line possesses the following features: halogen-free, ozone-resistant, with enhanced characteristics during fire conditions, and is applied in industrial facilities, infrastructure systems such as train stations, airports, hospitals, schools, supermarkets... With these mentioned characteristics, NHXMH-J/NHXMH-O cable line is suitable for installation in wet environments, outdoor environments as long as the cable is protected against the sunlight.

HELUDATA® EN-50288-7 FIRE RES OSA 500

DATA SHEET

HELUDATA® EN-50288-7 FIRE RES IOS 500

DATA SHEET

NHXMH-J / NHXMH-O

DATA SHEET6. Typical misunderstandings about fire-resistant cables

6.1 Fire-resistant cables are completely impervious to fire

One of the most common misconceptions is that fire-resistant cables are completely impervious to fire. Fire-resistant cables are designed to maintain circuit integrity for a specified period under fire conditions. However, they will not withstand fire if exposed for a prolonged period or at extremely high temperatures.

>>Find out more: Heat-resistant cables for the steel industry

6.2 All fire-resistant cables are exactly the same

Not all fire-resistant cables are created equally. Different types of fire-resistant cables are designed to withstand different levels of fire exposure and for varying durations. For example:

- Fire-resistant cable according to BS 6387 class C can withstand 950°C in 180 minutes.

- Fire-resistant cable according to IEC 60331 can withstand 750°C in 90 minutes.

- Fire-resistant cable according to BS 6387 type W can withstand 650°C and has the effect of water in 15 minutes.

6.3 Fire-resistant cables are immune to damage

Fire-resistant cables are indeed more resilient to fire damage compared to standard cables, but they are not immune to other forms of damage such as mechanical stress, chemical exposure, or water ingress. Proper handling, installation, and maintenance are still necessary to ensure the long-term reliability and performance of fire-resistant cables.

The use of fire-resistant cables is a joint effort to implement fire prevention and firefighting strategies. Other measures such as installing fire alarm systems and building design, also need to be coordinated to enhance comprehensive firefighting operations.

6.4 Fire-resistant cables and flame-retardant cables can be used interchangeably

Many people believe that fire-resistant cables and flame-retardant cables can be used interchangeably. However, while fire-resistant cables can often substitute for flame-retardant cables in normal circumstances, the latter cannot replace the former. Fire-resistant cables can continue to operate in the event of a fire, while flame-retardant cables are designed to prevent the spread of fire by stopping combustion. In addition to heat resistance, some types of fire-resistant cables are also waterproof and able to withstand impacts or vibrations.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

905, Nguyen Kiem Street, Ward 3, Go Vap District, Ho Chi Minh City 700000, Vietnam

Tel. +84 28 77755578 | info@helukabel.com.vn | www.helukabel.com.vn