What is wire cross-section? Considerations when selecting wire cross-section

Why do electrical cables have different cross-sectional areas? What factors should be considered when selecting the cross-sectional area of a conductor?

For industries, the consistent harmony of electrical systems plays a crucial role in ensuring operational productivity and the safety of electrical systems and machinery. Wire cross-section is the prerequisite for this integration and a systematic approach to meeting the essential needs of industries.

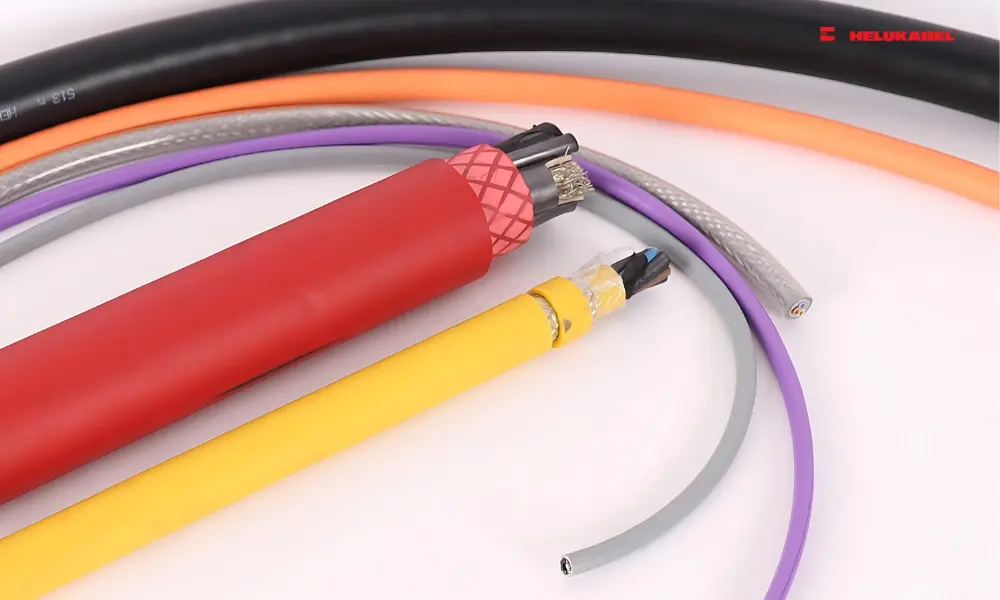

Technical Information: Common Types of Industrial Electrical Cables

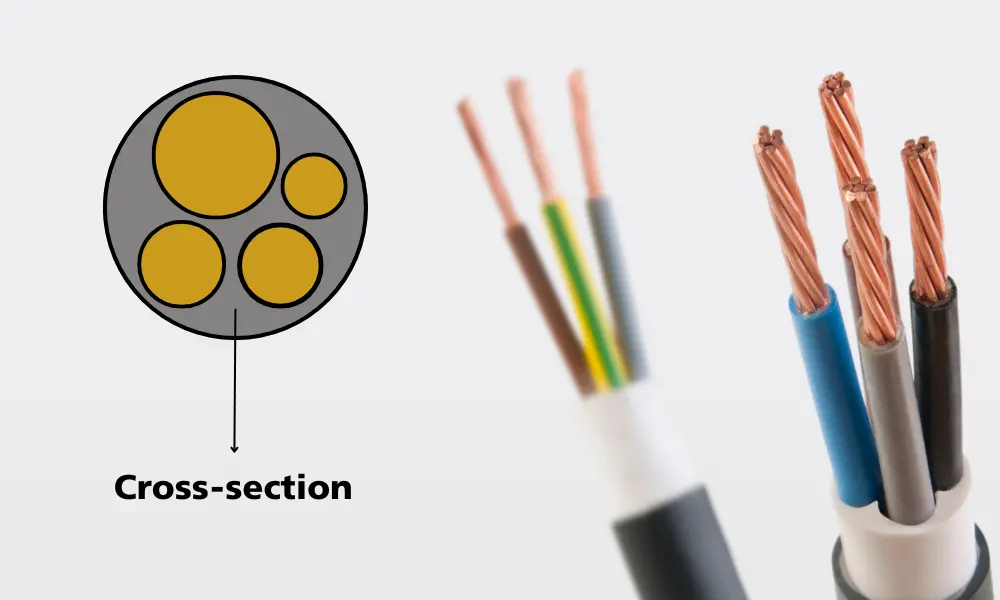

1. What is the cross-sectional area of an electrical conductor?

Cross-sectional area of electrical conductors

1.1 What is the cross-sectional area of a conductor?

In the field of electricity and electrical cables, cross-sectional area is commonly used to refer to the cross-sectional area of the conductor when cut perpendicular to the length of the wire. This conductor is a metal core (copper, aluminum, etc.) responsible for conducting electricity, not including the outer insulation layer.

- Unit of measurement: square millimeter (mm²).

- Function: an important parameter for calculating current-carrying capacity, determining how much electrical power a wire can transmit without overheating or causing significant voltage drop.

- Principle: The larger the cross-sectional area, the lower the resistance of the conductor, thereby allowing a higher current to flow and reducing energy loss.

Example: 4 mm² copper wire means that the cross-sectional area of the copper core is 4 mm², excluding the insulating sheath.

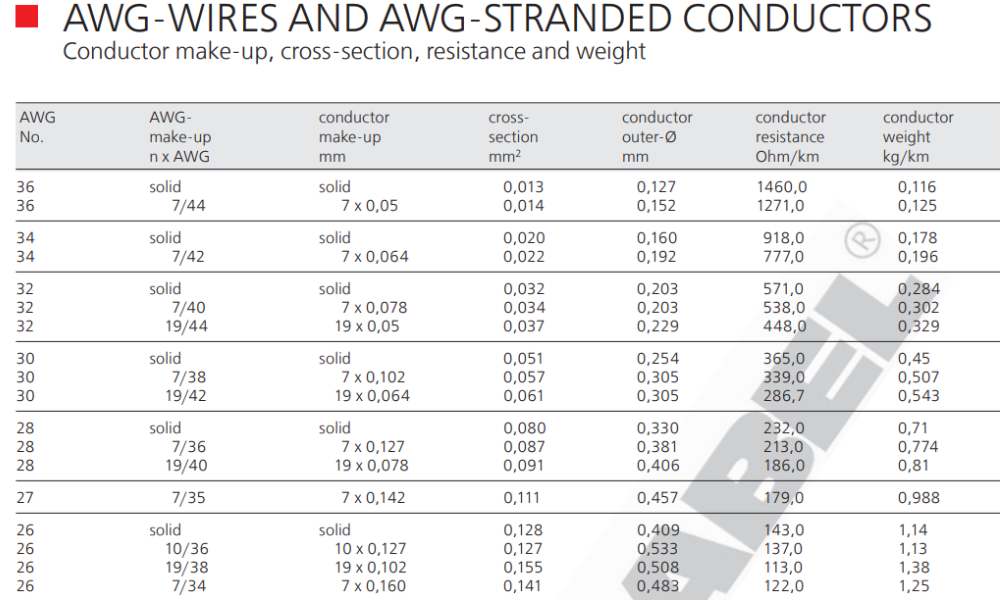

1.2 Copper wire cross-section conversion table

The copper wire cross-sectional area conversion table helps convert wire sizes from the AWG (American Wire Gauge) standard to familiar parameters such as diameter (mm) and cross-sectional area (mm²).

While Vietnam and Europe use mm², many imported devices are labeled according to AWG, so a conversion chart is essential for selecting the correct size. Note: the smaller the AWG number, the larger the wire – completely opposite to the calculation using mm².

For example, AWG 10 wire has a cross-sectional area of approximately 5.26 mm², while AWG 4/0 is approximately 107 mm² and can carry currents exceeding 200 A. When selecting wire, allow for a 10–20% capacity margin and prioritize internationally certified brands such as HELUKABEL to ensure safety, minimize losses, and meet industrial technical requirements.

1.3 The difference between the cross-sectional area of a conductor and the diameter of a cable

| Cable diameter | Cross-section | |

| Definition | The external dimension of the cable, measured on the outer insulation layer. | The cross-sectional area of the conductive metal core, excluding the insulation layer. |

| Unit | Millimeter (mm) | Square millimeter (mm²) |

| Meaning | Specify the overall size of the cable to help select conduit, cable trays, and connector accessories. | It is an important parameter for calculating current carrying capacity, voltage drop, and power loss. |

| Characteristics | Diameter only reflects external dimensions and is not directly related to current-carrying capacity. | With stranded wire, the cross-sectional area is the total area of all the small strands, even though there are gaps between the strands. Due to the gaps, the outer diameter of stranded wire can be up to 20% larger than that of solid wire with the same cross-sectional area. |

In summary:

- Diameter: the overall external size of the cable.

- Cross-sectional area: the internal area of the conductive metal, which determines the current-carrying capacity and transmission efficiency.

2. Distinguish between the three types of conductor cross-sections

2.1 Nominal cross-section

- Definition: The standard value specified in the product standard (e.g., 1.5 mm²; 2.5 mm²; 10 mm²).

- Characteristics: Only the name or specification code to identify the product. No requirement to directly measure the actual area of the conductor.

- Application: Used in technical documentation, manufacturing, electrical design, helping buyers and engineers easily select cables.

2.2 Cross Design Area

- Definition: The cross-sectional area value calculated during the design of an electrical system, ensuring adequate current-carrying capacity and resistance for the load.

- Characteristics: Based on the load current, cable length, allowable voltage drop, and installation conditions. This is the basis for selecting the cable size so that the conductor resistance (R) meets safety standards.

- Application: Mandatory in the design and installation of electrical distribution systems, especially for low-voltage and industrial networks.

2.3 Actual Cross-Section

Definition: The actual geometric area of the conductive metal core when cut perpendicular to the wire axis, measured in mm².

Features:

- Determined by direct measurement or sample testing.

- May be larger or smaller than the nominal value depending on the material:

- Good electrical conductor (pure copper) ⇒ the actual cross-sectional area can be smaller while still meeting the resistance standard.

- Poorer electrical conductors (aluminum alloys) ⇒ require a larger cross-sectional area to achieve the same level of electrical resistance.

Application: Used in quality control and production to ensure cables meet resistance standards.

3. Meaning of the cross-sectional area of a conductor

Electrical cables are the connecting factor that links all components together in an electrical system. Cables supply power from the power source to distribute to devices, machinery systems, etc. However, when installing electrical cables, one of the most common mistakes is choosing cables that are too small or too large for the actual needs.

Proper cable installation primarily involves determining the appropriate cable size, using the correct tools to attach the terminals, and providing adequate overcurrent protection with fuses and circuit breakers. Determining the cable size can be understood simply as the length of cable measured from the power source to the device and the current (amperage) that will run through it.

The longer the cable or the higher the current intensity, the larger the cable cross-section must be to avoid unacceptable voltage drops. There must always be ample margin to ensure safety because the equipment may actually draw more current than the rated value due to heat, low voltage, load, or other factors. When the cross-sectional area of an electrical cable is oversized, performance may not be affected. However, when the cross-sectional area of the conductor is smaller than required, electrical safety issues can pose a hazard.

>>See more: Guide to inspecting the quality of control cables

4. How important is the cross-sectional area of the conductor?

4.1 Selecting the correct wire cross-section maximizes performance

An efficient and effective industrial electrical system requires optimizing performance by carefully considering the cross-sectional area of electrical cables for specific applications. Power losses and voltage drops caused by undersized cables and increased resistance will affect the overall performance of equipment and machinery. The efficiency and reliability of equipment can be hampered by excessive voltage drops. Accurate cable cross-sections address voltage drop concerns, helping to improve the lifespan and performance of machinery.

Therefore, the appropriate conductor cross-section ensures that the power transmission process runs smoothly without interruption. This also helps prevent potential failures and thus improves the productivity of the machinery.

4.2 Cost savings and ensuring economic efficiency

Choosing the right cable cross-section helps save on initial investment costs. Cables that are too large are much more expensive than cables with the right cross-sectional area for the application. In addition, the cross-sectional area of the conductor significantly affects energy efficiency, which is the foundation of modern industrial operations. Cables with an inefficient cross-sectional area lead to power loss, thereby generating more heat and wasting energy.

4.3 Ensuring the safety of the electrical system

The purpose of any electrical cable is to transmit electrical energy over a certain distance with the least resistance. The greater the need to transmit energy and connect devices, the larger the cable cross-section must be. If the cable cross-section is too small, the cable will be damaged and the insulation will melt due to the current flowing through the cable being greater than the rated capacity. The smaller the cable diameter, the higher the resistance to the energy flow. High resistance generates heat, causing a risk of fire or explosion. Therefore, the wire cross-section plays an important role in minimizing potential hazards, protecting the workforce and the enterprise's assets.

>>See more: Technical information: What is electrical resistance?

4.4 Selecting the correct conductor cross-section to ensure the service life of electrical cables

If the cross-sectional area of the conductor is used in unsuitable industries, it can generate excessive heat sufficient to destroy sensitive components, thereby reducing the lifespan of any machinery. At the same time, properly installed electrical cables ensure that specific equipment operates under normal working conditions without excessive strain or potential failure.

By sizing cables appropriately to extend their service life, businesses can avoid disruptions caused by downtime and maintenance, while strengthening their infrastructure against unforeseen circumstances. This approach delivers strategic benefits through increased reliability, extended equipment lifespan, and ensuring smooth operation.

4.5 Ensure compliance with standards and regulations

In an industrial environment, compliance with standards is fundamental, and fulfilling administrative prerequisites through wire sizing is an important part of this. For example, according to the National Standard TCVN 9208:2012 on "Installation of cables and electrical wires in industrial facilities," the size of electrical cables is specified as follows:

| Electrical insulation | Coating | Outer diameter d of the cable (mm) | Minimum bending radius of the cable (calculated in terms of the number of outer diameters of the cable) |

| Rubber or PVC insulation with copper or aluminum multi-strand braided core | Not armored | Up to 10 | 3 |

| Greater than 10 and up to 25 | 4 | ||

| Rubber or PVC insulation with copper or aluminum multi-strand braided core | Not armored | Over 25 | 6 |

| Steel casing | Any | 6 | |

| PVC insulation with copper or aluminum core | Steel-clad or non-steel-clad | Any | 6 |

| Oil-impregnated paper insulation | Lead sheathing | Any | 6 |

| Inorganic insulation | Copper or aluminum cladding with or without PVC | Any | 6 |

5. Factors affecting the selection of electrical cable cross-section

When selecting the cross-sectional area of conductors for specific applications, users should consider the following factors:

5.1 Electrical cable installation methods

This is the first thing to consider because the method and location of electrical cable installation will directly affect whether the cable can be overloaded (e.g., in conduits, on cable trays, free installation, etc.). In general, if you choose to install cables in a more enclosed space (e.g., in conduits versus free installation), you will need to use a larger cable cross-section to ensure that the current is not attenuated, and the installation spacing (gap) between the wires must be reasonable so that the electrical transmission performance is not affected.

>>See more: Top 4 types of electrical cables suitable for outdoor installation

5.2 Insulating sheath of electrical cables

Insulating materials play a crucial role in determining the size of electrical cables because they directly affect the maximum operating temperature of the cable. Common insulating materials include PVC, XLPE, and EPR rubber.

The maximum operating temperatures for PVC, XLPE, and EPR rubber are 70°C, 90°C, and 90°C, respectively. Although PVC has a lower operating temperature, it is the optimal choice in certain situations. This relates to other material properties that perform better in your installation environment. For example, PVC is much more flexible than XLPE and may be a better choice when you require cables to bend in tighter spaces.

You can also choose between single-core or multi-core cables depending on your installation requirements, which will also affect the cable's current-carrying capacity. Single-core cables dissipate heat better than multi-core cables and therefore have a higher current-carrying capacity. However, you can still choose multi-core cables because installing the necessary conductors may be easier.

>>See more: How do PVC cables and LSZH cables differ?

5.3 Length of electrical cable

Ensuring that power transmission lines receive optimal voltage with minimal voltage drop is crucial. Cables with smaller diameters inherently have higher resistance, leading to increased voltage drop. Therefore, selecting cables with minimal or no voltage drop is essential. The cross-sectional area and length of the cable primarily determine the voltage drop in the circuit. The smaller the cable cross-sectional area or the longer the cable length required for your circuit, the greater the voltage drop.

>>See more: Learn about the AWG rating of electrical cables

5.4 Load reduction factors

The current rating or current intensity of cables is easily affected by external interference, requiring the application of attenuation factors for accurate calculations. Key load reduction factors that cannot be overlooked when considering the cross-sectional area of electrical cables include:

- Temperature reduction coefficient (CT): Specified by standards such as IEC 60287 and NEC 310.16, the temperature reduction coefficient takes into account cable arrangement to minimize heat dissipation. This factor plays a key role in improving cable amplification by considering spatial arrangement to minimize heat loss.

- Conductor Grouping Factor (CG): According to standards such as IEC 60287 and NEC 310.16, the electromagnetic field around conductors grouped together will reduce the amplification of the cable. The conductor grouping factor is introduced to address this effect and ensure accurate cable sizing.

- Thermal resistance of soil (CR): Recognizing that cables buried in soil experience temperature changes, standards such as IEC 60287 and NEC 310.16 incorporate the thermal resistance factor of soil. This factor compensates for the temperature increase, enabling accurate calculations.

- Burial Depth Reduction Factor (CD): Depending on the burial depth of the conductor, the burial depth reduction factor, influenced by standards such as IEC 60287 and NEC 310.16, will take effect. Deeper burial increases the attenuation factor, requiring careful consideration when calculating cable cross-section.

6. Common cross-sections of conductors

6.1 16 AWG electrical cable

16 AWG electrical cable, equivalent to a core diameter of approximately 1.5mm², is one of the most commonly used wire cross-sections and is widely used.

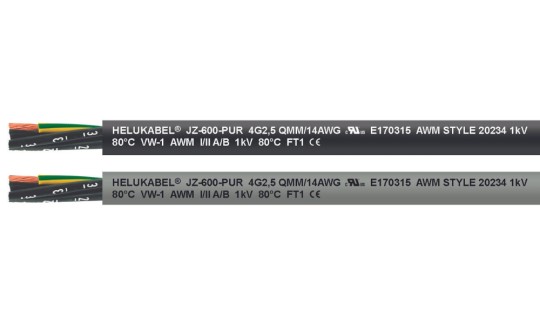

JZ-600 PUR Control Cable

JZ-600 PUR is a highly flexible control cable line featuring outstanding characteristics such as abrasion resistance, UV resistance, mineral oil resistance, and coolant resistance. Therefore, this type of electrical cable is used in machine tools, conveyor belts and production lines, installed in factories, air conditioning systems, steel mills, and rolling mills.

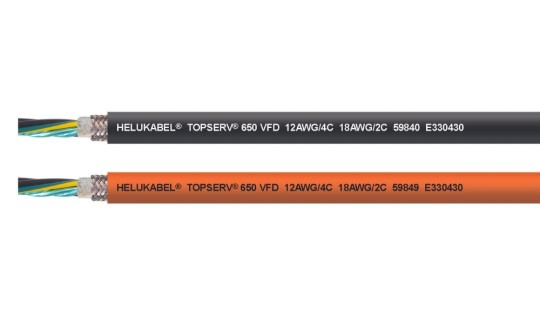

TOPSERV® 650 Variable Frequency Drive

TOPSERV® 650 VFD electrical cables offer high flexibility and exceptional oil resistance for modern servo motors; the tin-plated copper shielding (with approximately 85% coverage) provides effective protection against electrical interference and resulting damage. The special TPE sheath has extremely high resistance to oil, coolants, and solvents, making it the perfect solution for industrial applications involving exposed installation, installation in conduits, or installation in the ground. Furthermore, this cable line is also suitable for use in cable chains.

6.2 Electrical cable with a conductor cross-sectional area of 18 AWG

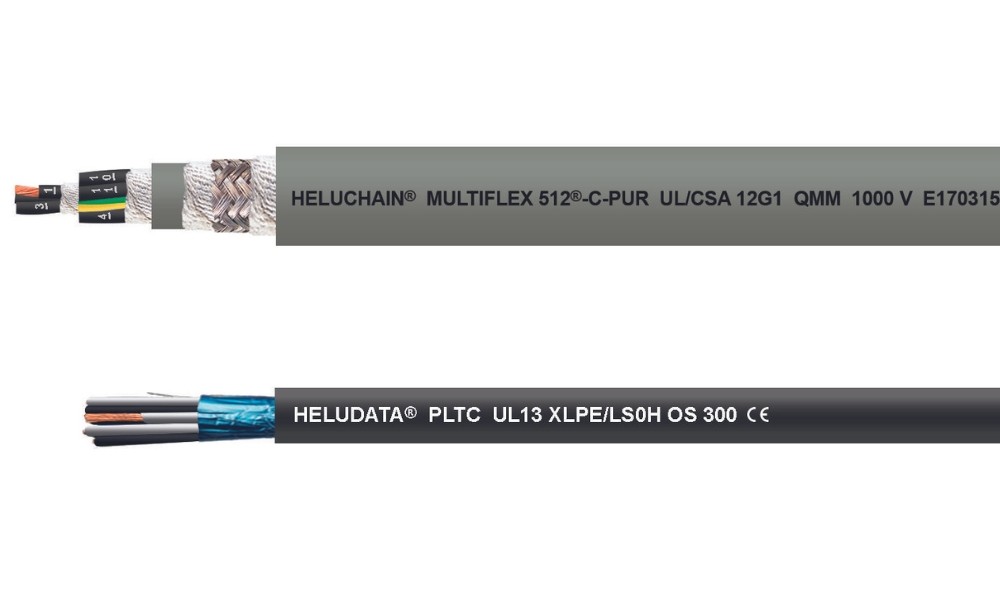

HELUCHAIN® MULTIFLEX 512®-C-PUR UL/CSA

HELUCHAIN® MULTIFLEX 512®-C-PUR UL/CSA is an electrical cable product approved by UL/CSA for use in machine and tool manufacturing, robotics manufacturing, and other continuously moving machine parts; for flexible applications with free movement without tensile stress and without motion control in dry, wet, and outdoor environments. The smooth, insulated PP core is cut-resistant, and the low-adhesion PUR outer jacket ensures optimal durability and cost-effectiveness.

HELUCHAIN® MULTIFLEX 512®-C-PUR UL/CSA Electrical Cable Datasheet

HELUDATA® PLTC UL13 XLPE/LS0H OS 300

This cable line offers advantages such as: low smoke, halogen-free (LS0H), hydrocarbon resistance, low signal attenuation, and low mutual capacitance, enabling long transmission distances. The cable elements are manufactured using moisture-resistant materials. Therefore, this cable line is used to transmit digital and analog signals in harsh environments such as the oil and gas and petrochemical industries. The cable is suitable for fixed installation in dry and wet locations, open spaces, and underground networks.

TRAYCONTROL® 500

HELUKABEL® TRAYControl® 500 is a flexible, oil-resistant control cable. The unique combination of TC-ER, PLTC-ER, and ITC-ER allows this cable to be used as a connection cable for industrial plants and machinery in accordance with NFPA 79 standards. The superior oil resistance of this cable line (OIL RES I & II) ensures long service life for industrial applications in dry and wet environments. Recommended applications: production lines, bottling plants, machine construction, switch cabinets, conveyor systems, packaging machinery, automotive industry.

If you still have questions, don't hesitate to contact HELUKABEL Vietnam's team of engineers for detailed answers.

HELUKABEL® Vietnam

| Address | 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000 |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover and purchase our products on | Tiki | Shopee | Lazada | Product finder |

| Connect with us on | Facebook | LinkedIn | Instagram | YouTube | Zalo | WhatsApp | TikTok | Spotify |