Anti-rodent solutions for DC cables and fiber optic cables

Anti-rodent fiber optic and DC cables are specially designed to prevent damage caused by rodents such as rats and mice. These cables are typically equipped with protective layers made of steel, glass yarn, or other chew-resistant materials, ensuring safety, durability, and extended service life for the cable system.

Rodents such as rats naturally tend to gnaw on various objects, including electrical cables - leading to serious problems for electrical systems. With their sharp incisors, they can chew through the insulation, exposing conductor and causing significant damage. As a result, repair costs are often high because many damaged cables must be replaced entirely to restore safe system operation.

1. Why do rodents tend to gnaw on DC cables and fiber optic cables?

Some installation locations of DC cables and fiber optic cables facilitate the development of rodents.

Rodents are highly adaptable creatures that often seek warm, concealed areas to nest and reproduce. Electrical cables are typically installed in locations that are both hidden and capable of retaining heat, making them attractive to these animals.

Cables can be found in attics, basements, inside walls, or technical rooms - dark and well-insulated spaces. Heat generated by current flowing through the cables warms these areas, attracting rodents. In addition, such locations provide shelter and allow rodents to move around and chew on cables without being noticed.

The combination of warmth and concealment not only encourages rodent intrusion but also increases the likelihood of them encountering and gnawing on cables. This instinctive behavior can cause damage that affects the entire electrical system. Therefore, preventive measures —such as using cables with rodent protection - are crucial in high-risk areas.

The level of risk depends on several factors, including the specific rodent species, installation method, and geographic region. For example, directly buried fiber optic cables are more susceptible to attacks from field rats, while aerial cables are frequently damaged by squirrels —especially in areas where trees near the cable route allow easy access.

2. Common problems caused by rodent damage to electrical cables

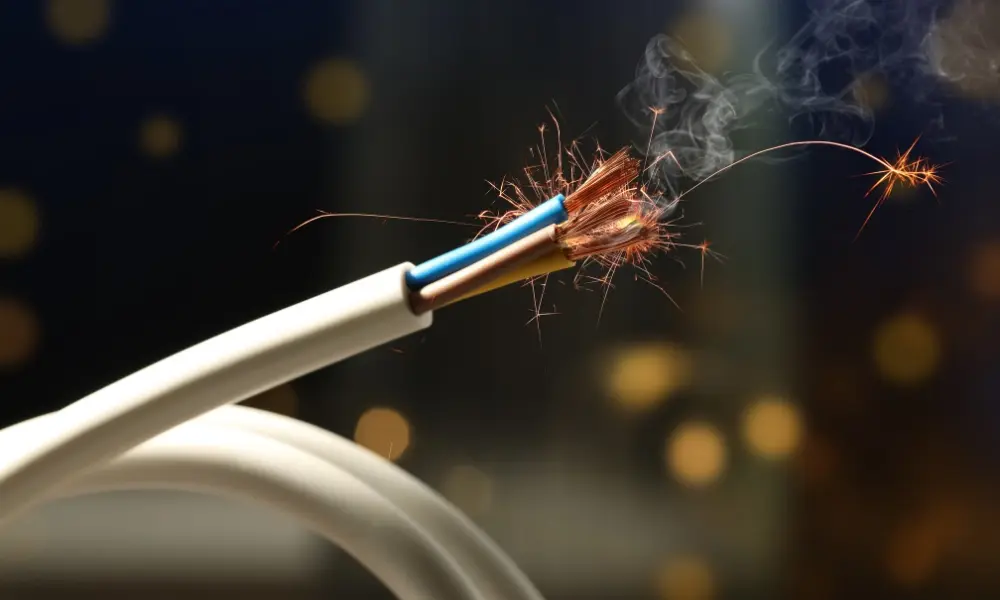

The threat posed by rodents to photovoltaic systems

2.1 Short circuits and system failures

Short circuits due to exposed conductors: When rodents chew through the insulation, the copper or aluminum conductor becomes exposed. If two conductors come into contact, or if one touches a conductive surface, the electrical current is diverted, resulting in a short circuit. Common consequences include sudden power outages, circuit breakers tripping repeatedly, or blown fuses. In more severe cases, the surge in current generates excessive heat, which can melt the conductor and potentially lead to fire hazards.

Unstable or non-functioning equipment: Once insulation is compromised, the electrical supply to equipment becomes unstable. Devices may operate erratically, shut down unexpectedly, or fail completely. This is especially dangerous in industrial control systems, where damage to even a single cable can halt an entire production line.

Reduced performance of industrial machinery: In factories or production facilities, rodent damage to cables can disrupt key components such as control cabinets, sensors, and drive systems. Equipment downtime slows production schedules, causes operational delays, leads to substantial financial losses, and increases safety risks for operators.

Risk of fire or explosion due to rodent damage

2.2 Increased risk of fire and explosion due to exposed conductors

Short circuits generating heat and sparks: Once the conductor is exposed, even minor unintended contact can create electrical sparks. If flammable materials such as wood, insulation, or fabric dust are nearby, the likelihood of ignition becomes very high.

Overheating due to loss of insulation: When electrical cables lose their insulation layer, they dissipate heat more intensely than normal. If the cable continues to carry load for an extended period, the remaining sheath or surrounding materials may ignite. This is especially dangerous in areas where cable density is high, such as ceilings, electrical cabinets, or technical ducts.

Difficulty in early detection: A key danger of rodent-induced electrical fires is that they commonly start in hidden locations - inside walls, under floors, or in attics. Smoldering fires can burn for hours before becoming visible, leading to extensive structural damage.

2.3 High repair and maintenance costs due to frequent cable replacement

Recurring cable replacement costs: Any cable section damaged by rodents must be replaced. In facilities with complex electrical systems, cable replacement requires significant materials and manpower. If rodent-resistant or specialized cables are used, the cost becomes even higher.

High labor costs due to difficult cable access: Repairing rodent damage involves more than simply replacing the cable. Workers often need to remove ceiling panels, wall sections, or cable trays to reach the damaged area. This increases labor costs, repair time, and hourly technical service fees.

Operational downtime and reduced productivity: In industrial environments, even a single damaged power or signal cable can shut down machinery. This leads to productivity loss, reduced revenue, and delays in delivery schedules or customer service.

Repeated maintenance if the root cause is not addressed: If rodent nests or entry points are not eliminated, the problem is likely to recur. Facility owners will face ongoing inspections, maintenance, and repairs - resulting in repetitive costs that are both expensive and disruptive over the long term.

3. Anti-rodent solutions for DC cables and fiber optic cables

There are various methods to protect electrical cables from rodent damage. Some common solutions include:

3.1 Using corrugated steel armouring with copolymer coating

This is one of the most widely used methods for protecting fiber optic cables from rodent attacks. Many telecommunications providers today use corrugated steel tape with a copolymer coating as an effective anti-rodent barrier. With this structure, the cable core is almost completely protected from rodent bites.

Fiber optic cables equipped with corrugated steel armouring offer higher flexibility compared to cables reinforced with galvanized steel tape or galvanized steel wires. Additionally, these cables have smaller diameters and lower weight than those armoured with galvanized steel or large steel wire strands, making installation and handling easier.

3.2 Using galvanized steel armouring

In practical fiber optic applications, galvanized steel armoring is typically placed between the inner sheath and outer sheath. This structure provides nearly 100% protection for the cable core against rodent attacks.

Cables with this type of reinforcement are often used in environments with harsh operating conditions, such as areas requiring high compressive strength, strong impact resistance, or greater tensile strength.

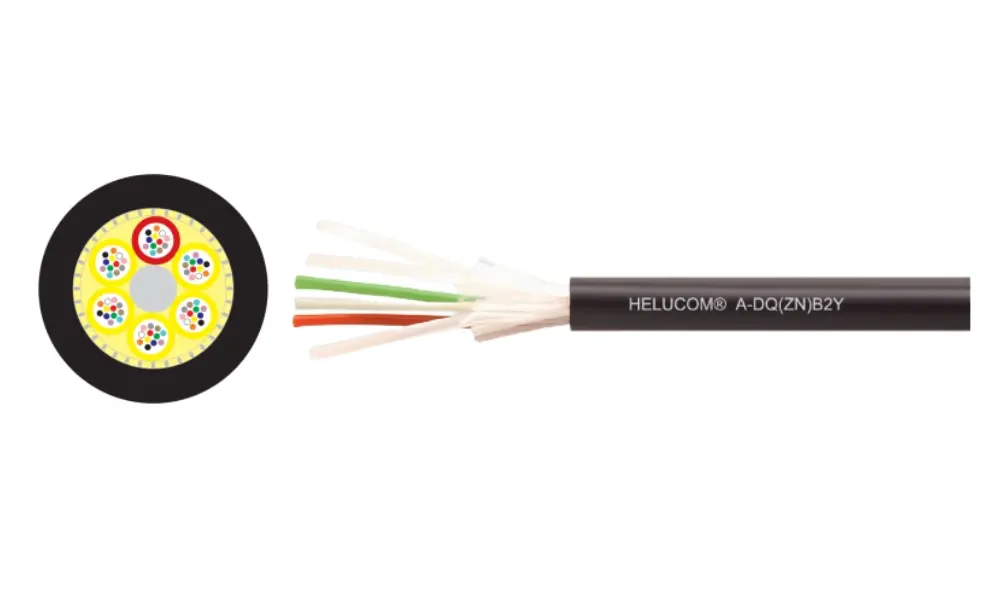

A-DQ(ZN)B2Y optical cable, stranded with GRP non-metallic armor

3.3 Using non-metallic armour – Flat GRP or Flat FRP

This method is commonly applied to fiber optic cables that contain no metallic components. In this structure, a special non-metallic material - either flat GRP (Glass Reinforced Plastic) or flat FRP (Fiber Reinforced Plastic) is placed on the cable core or between the inner and outer sheaths. This non-metallic armor protects the cable against rodent damage.

Another advantage of this cable type is that grounding is not required, as it contains no metallic layers.

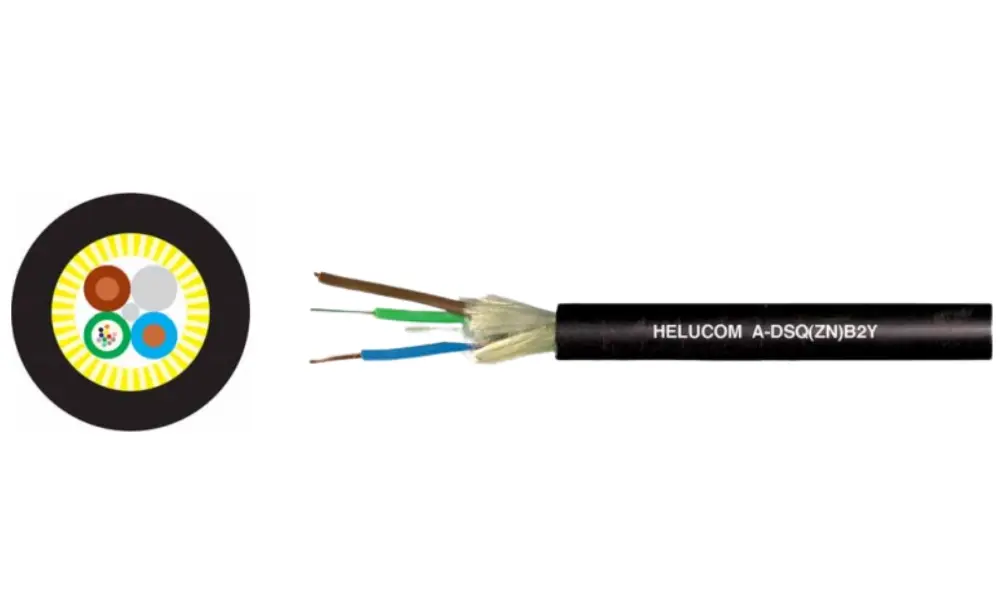

A-DSQ(ZN)B2Y fiber optic cable with glass yarn armour

3.4 Using glass with a specific density on the core or inner sheath

In recent years, another increasingly popular method for protecting fiber optic cables from rodents is the use of glass fibers applied with a specific density (by weight) on the cable core or inner sheath.

This solution effectively protects the cable from small rodent species. Even if rodents manage to damage the outer sheath, they are unable to penetrate the glass fiber layer to reach the cable core.

One of the main reasons is that glass fibers are brittle and can irritate or injure the rodent’s mouth or tongue, discouraging them from biting or chewing further.

3.5 Applying chemical additives to the outer sheath of cables

In this method, special chemical additives that deter rodents are incorporated into the cable’s outer sheath. These additives protect the cable by creating an unpleasant taste or emitting an odor when rodents approach or attempt to chew on the cable, discouraging them from gnawing.

From a cost-effectiveness and ease-of-application standpoint, adding a certain amount of rodent-repellent agents (such as capsaicin) to the cable sheath is considered an effective option - provided that long-term anti-rodent performance can be ensured. However, this approach poses several challenges regarding environmental safety and product durability:

- Evaporation during production: When capsaicin is mixed with sheath materials and extruded, a substantial amount of pungent vapor is released. This vapor spreads quickly through the workshop and can negatively impact respiratory health.

- Loss of capsaicin in outdoor environments: Over time, capsaicin gradually dissipates from the cable sheath material, reducing the long-term effectiveness of the rodent-repellent properties.

Because of these issues, chemical-based rodent protection is generally not recommended.

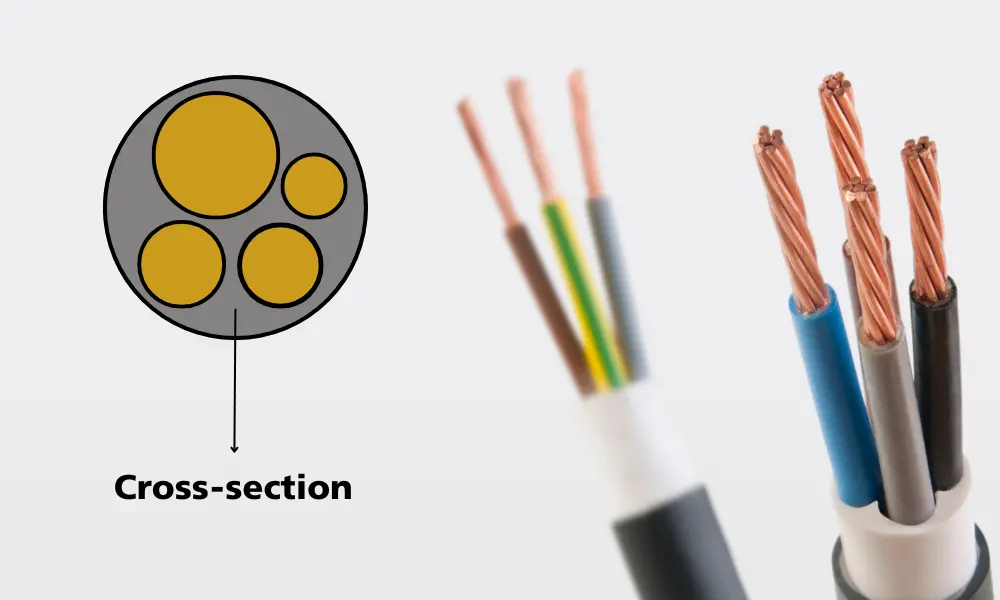

The thickness of electrical cables affects their resistance to rodent damage

3.6 Cable materials and sheath thickness

The materials used in cable construction play an important role in protecting cables from rodent damage. Certain durable materials with strong mechanical properties are difficult for rodents to chew through, making them less likely to approach. Examples include:

- Cables with XLPE outer sheaths: Known for their high mechanical strength and excellent chemical resistance, XLPE provides a tough, rigid layer that is difficult for rodents to penetrate.

- Cables with PVC outer sheaths: A common and cost-effective option, PVC offers good flexibility while still delivering a reasonable level of protection against rodent-related damage.

Another important factor is the thickness of the outer sheath. Thicker sheaths generally offer better protection. Manufacturers can adjust the sheath thickness during production to enhance rodent resistance. However, there must be a balance between thickness and cable flexibility, as an overly thick sheath may make the cable stiff and difficult to install.

4. HELUKABEL electrical cables for rodent protection

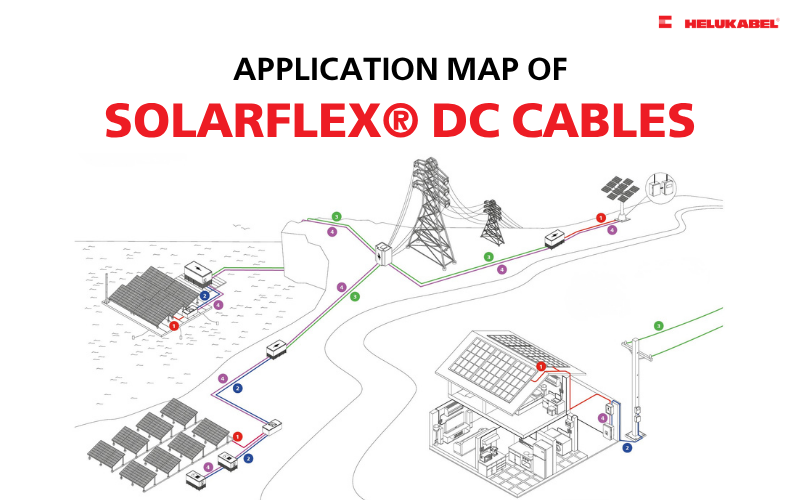

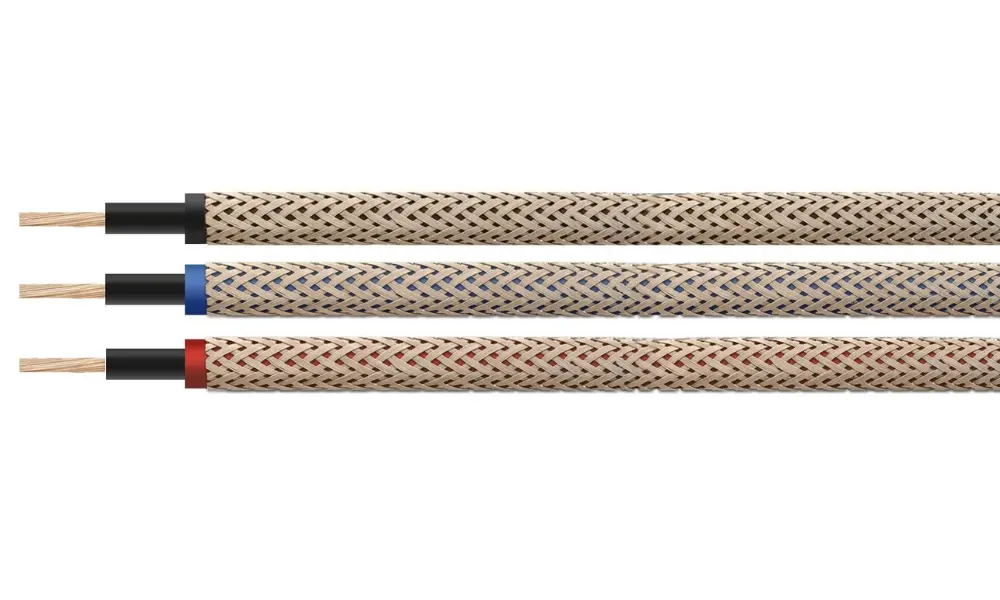

4.1 Anti-rodent DC cables

In certain installation environments such as tropical climates, outdoor setups, or agrivoltaic solar systems, DC cables face significant challenges from rodents. To address this issue, HELUKABEL offers the SOLARFLEX®-X H1Z2Z2-K NTS DC cable with the following features:

- Reinforced with V2A stainless steel braid: Enhances mechanical strength and provides effective protection against rodent damage.

- Tinned copper conductors, Class 5: Improves resistance to oxidation and abrasion, increasing cable durability.

- Cross-linked insulation and outer sheath: Enhances mechanical properties and offers robust protection against environmental impacts.

Some HELUKABEL fiber optic cable products have a glass yarn armor layer.

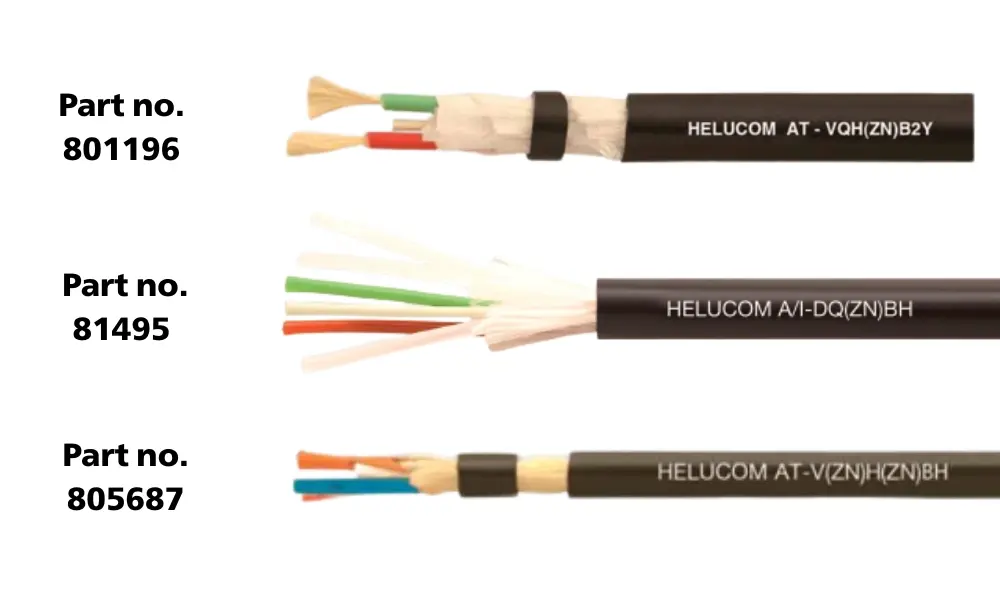

4.2 HELUKABEL fiber optic cables with glass yarn armour

Our HELUCOM® fiber optic cable range is designed for easy installation and effective rodent protection. Surrounding the fiber is a layer of glass yarn armour combined with swelling fleece, providing the cable with the following advantages:

- Protection against rodents, including rats and mice

- Reduced tensile stress on the cable

- Longitudinal water-blocking along the cable length

In addition to the glass yarn armor, HELUKABEL fiber optic cables are also equipped with a strain relief element. This component is essential for guiding and protecting the cable in industrial applications, offering the following benefits:

- Reduces mechanical stress and extends cable lifespan

- Provides high retention force, effectively protecting the cable

- Speeds up installation

- Optimizes installation space

| Fiber optic cable products | Strain relief element | Number of optical fibers | Key advantages | Part number |

| A/I-VQ(ZN)BH | Aramide | 4 - 12 | Space-saving design | 82804 |

| A/I-DQ(ZN)BH | Glass yarns | 4 - 24 | Halogen-free, CPR Eca | 82792 |

| A/I-DQ(ZN)BH, central | Glass yarns | 4 - 24 | 80270 | |

| A/I-DQ(ZN)BH, stranded | Glass yarns, with additional GRP reinforcement layer | 24 -96 | 81495 | |

| A/I-DQ(ZN)BH | Aramide | 4 - 12 | Ensure functional integrity according to DIN 4102-12 E30 (30 minutes) standard. | 801217 |

| A-DQ(ZN)B2Y, central; A-DQ(ZN)B2Y, central | Glass yarns | 2 - 24 | Good resistance to gnawing, tensile strength, water resistance along the length of the cable | 800754 / 80196 |

| A-DQ(ZN)B2Y, stranded | Glass yarns | 24 - 144 | 81382 | |

| A-DQ(ZN)B2Y fiber combo, stranded | Glass yarns, with added GRP reinforcement | 24 - 48 | 803037 | |

| A-DF(ZN)B2Y | Aramide, with an additional GRP reinforcement layer | 2 - 144 | 80100 | |

| A-DSQ(ZN)B2Y | Glass yarns | 4 | Specifically designed for temperature measurement applications using fiber optic cables | 81209 |

| AT-V(ZN)HH(ZN)B2Y | Aramide | 4 | 801352 | |

| AT-V(ZN)H(ZN)BH | Aramide | 4 | Can be used for PROFIBUS and PROFInet communication protocols | 805687 |

| AT-V(ZN)H(ZN)BH; AT-WQ(ZN)H(ZN)B2Y | Aramide, with an additional GRP reinforcement layer | 2 | 805445 / 805692 | |

| AT-VQH(ZN)B2Y | Aramide, with an additional GRP reinforcement layer | 2 | Transmission distance up to 300m | 801196 |

4.3 Other anti-rodent fiber optic cables from HELUKABEL

In addition to fiber optic cables with glass yarn armour, HELUKABEL also offers other fiber optic products with effective rodent protection, including:

| Fiber optic cable products | Armour | Strain relief element | Number of optical fibers | Key advantages | Part number |

| A/I-D(ZN)BH(SR)H | Steel tape | Glass yarns | 4 - 12 | Ensure functional integrity according to IEC 60331-25 standards for 90 minutes (up to 750°C) | 803917 |

| A-DF(ZN)2Y4Y | PA | Aramide | 2 – 144 | 80915 | |

| A-DQ(ZN)(SR)2Y | Steel rib | Glass yarns | 4- 24 | 802917 | |

| A-DF(Zn)₂Y(Sr)₂Y | Steel rib | Aramide | 12 - 60 | 805244 | |

| A-DF(Zn)₂Y(Sr)₂Y | Steel rib | Aramide | 12 - 144 | Suitable for the telecommunications sector that needs to meet ARCOR standards | 82190 |

4.4 Cable protection accessories

To further protect DC or fiber optic cables from rodent damage, users can consider using the following cable protection accessories during installation:

- Cable conduit: Provides mechanical protection from certain environmental factors.

- Braided sleeves: Enhances the mechanical protection of the cable.

If you still have questions, don't hesitate to contact HELUKABEL Vietnam's team of engineers for detailed answers.

HELUKABEL® Vietnam

| Address | 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000 |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover and purchase our products on | Tiki | Shopee | Lazada | Product finder |

| Connect with us on | Facebook | LinkedIn | Instagram | YouTube | Zalo | WhatsApp | TikTok | Spotify |