Comparing cables vs wires: Features, classifications and applications

In the field of electrical connection, the terms “cable” and “wire” are often used interchangeably, which can easily lead to confusion. However, these are two distinct concepts, and each plays a specific role in different applications. This article will compare electrical wires and electrical cables - highlighting their similarities and differences - to help you better understand their characteristics and common uses.

1. Understanding wires

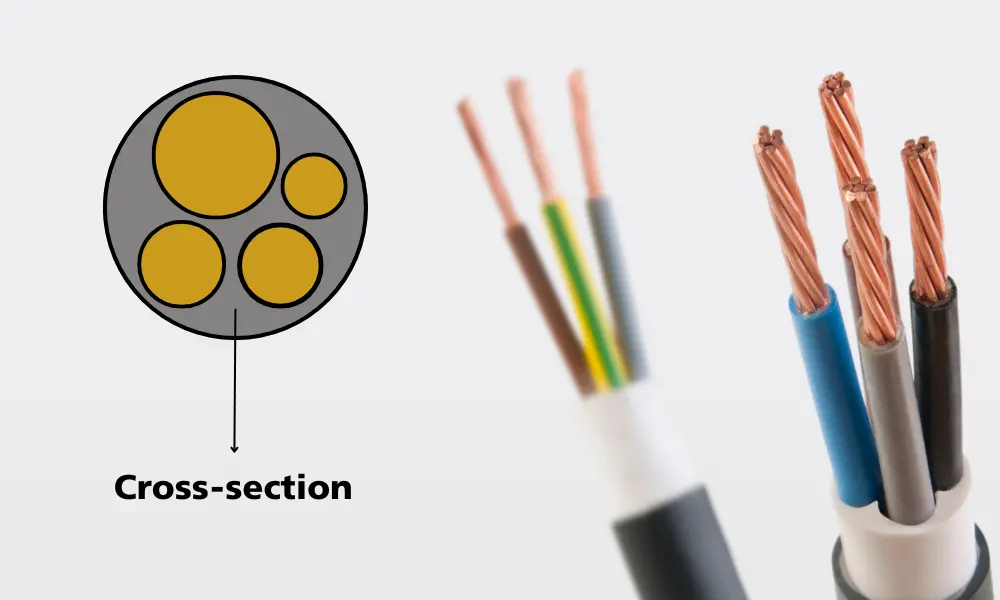

The cross-sectional area of electrical conductors is typically specified by the AWG rating or in mm².

1.1 What is an electrical wire?

An electrical wire is a single electrical conductor, which may be insulated or bare conductor, and is typically made of copper or aluminum. The insulation is a protective plastic layer applied directly over the conductor. In many cases, the term “wire” can be interpreted as an insulated conductor.

The cross-section of a wire is commonly specified using either the American Wire Gauge (AWG) standard or in square millimeters (mm²). AWG is a sizing system that determines the wire’s thickness based on the conductor’s diameter. The smaller the AWG number, the bigger the wire’s diameter and the higher its current-carrying capacity.

Although AWG is most often applied to solid wires, it is also used for stranded wires and cables. In these cases, the AWG value represents the total conductor cross-sectional diameter.

Learn about the significance of the AWG rating for electrical wires and cables

1.2 Function of wires

The primary function of an electrical wire is to provide a low-resistance pathway for electrons to flow from a power source to a load, thereby completing the circuit and enabling efficient energy transmission. Wires connect electrical components such as switches, outlets, and appliances, ensuring safe and controlled power distribution throughout the system.

THERMFLEX® 180 EWKF electrical cable with tin-plated copper core

1.3 Types of wires

There are two primary types of electrical wires: solid wire and stranded wire:

- Solid wire: The conductor consists of a single, continuous metal strand that can be bent to a certain extent. Solid wires offer lower electrical resistance and higher mechanical durability compared to stranded wires. They are often used in fixed installations or applications that require high-frequency performance.

- Stranded wire: Made up of multiple smaller solid strands twisted or braided together to form a single conductor. Stranded wires are typically insulated and are more flexible than solid wires, making them suitable for tight spaces or applications requiring frequent bending.

Both types of wires can also be incorporated as conductors within cable structures and may include additional protective insulation or jacketing depending on application requirements.

Another commonly used wire type is tinned copper wire. The tinning process involves coating the copper surface with a thin layer of tin, providing corrosion resistance, enhancing solderability, and preventing oxidation.

Examples of HELUKABEL tinned copper wire products include:

SOLARFLEX®-X H1Z2Z2-K NTS ,

THERMFLEX® 180 EWKF ,

TRAYCONTROL® 300-C TP,

HELUDATA® TRONIC-CY 2464 / 300 GREY, and H

HELUDATA® TRONIC-CY 2464 / 300 BLACK

1.4 Applications of wires

Electrical wires are ideal for direct or point-to-point connections. They are commonly used in household appliances, small devices, lighting systems, and short-distance power transmission. Their flexibility and compact size make them suitable for confined spaces or use inside electrical equipment.

Wires in electronic devices: Widely used to connect internal components such as speakers, fans, and computers. They are lightweight, flexible, and easy to route through limited internal spaces. Solid wires are preferred for precise internal wiring where only low voltage and minimal current are required.

Wires for maintenance and quick repairs: When restoring damaged electrical connections - such as in ceiling lights or small home appliances - wires are an accessible and simple solution. They allow easy reconnection or replacement without the complexity of handling multi-core cables.

Grounding wire is marked in yellow/green

1.5 Distinguishing phase, neutral, and ground wires

In an AC (alternating current) electrical system, three commonly used terms for electrical conductors are phase wire, neutral wire, and ground wire. Their differences are as follows:

- Phase wire (hot wire): This conductor carries voltage and delivers electrical energy to power devices and equipment.

- Neutral wire: This conductor does not normally carry current, but it completes the electrical circuit by returning current back to the source. In other words, the neutral wire provides a return path, enabling current to flow through the load. Without a neutral wire, the circuit would remain open and current would not flow.

- Ground wire (earthing/grounding conductor): This conductor safely channels any fault current to the earth — a zero-potential point — helping reduce the risk of electrical hazards. The ground wire is commonly identified with green-yellow insulation.

2. Understanding electrical cables

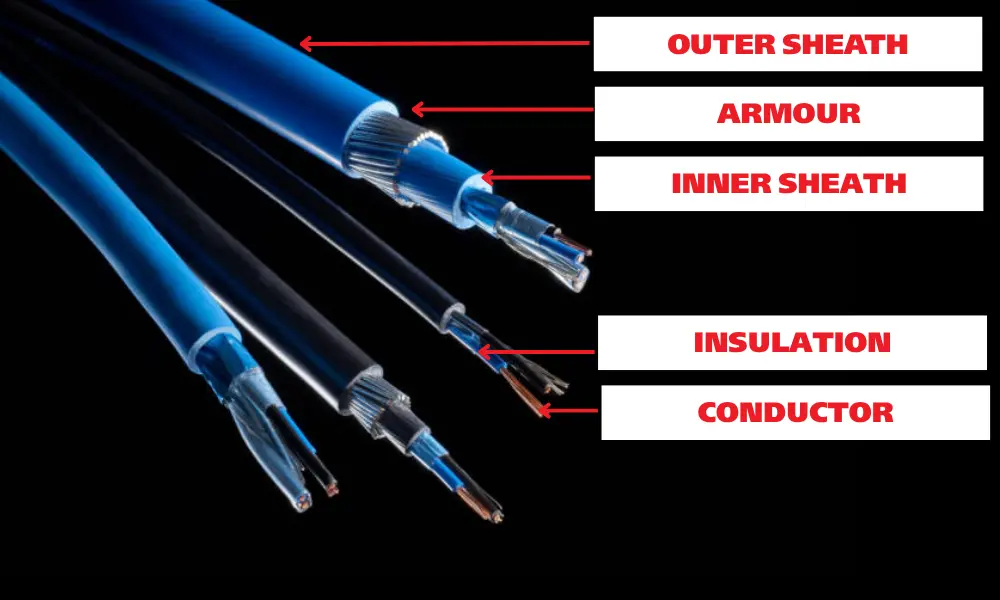

Construction of electrical cables

2.1 What are electrical cables?

An electrical cable is composed of multiple conductors bundled together, which may be layered, twisted, or braided. The basic structure of a cable typically includes: a conductor, insulation, and an outer sheath.

- Conductor: Responsible for transmitting electrical energy. Copper is commonly used due to its excellent conductivity, while other materials such as aluminum or copper-clad aluminum (CCA) are also applied.

- Insulation: Provides electrical isolation for the conductor, preventing current from flowing to unintended components or paths.

- Outer sheath: Protects the cable against mechanical impact, human contact, moisture, chemicals, and other environmental factors.

In addition, some electrical cables are reinforced with extra layers such as armouring or shielding to enhance mechanical strength or reduce electromagnetic interference (EMI).

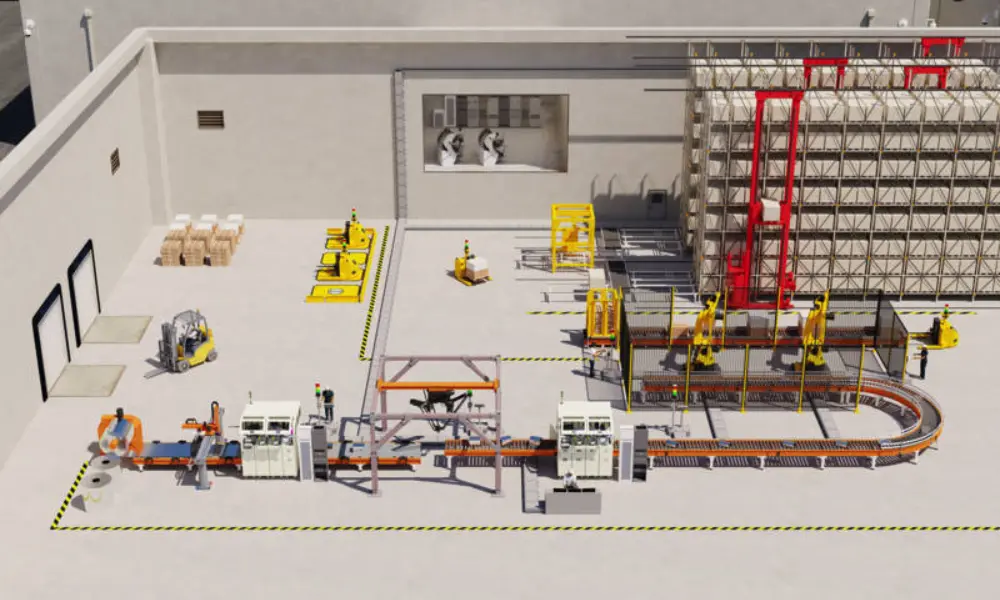

Electrical cables not only transmit energy but also play a vital role in the entire industrial system.

2.2 Functions and applications of electrical cables

Electrical cables not only transmit power but also play a critical role throughout industrial systems. Depending on the cable type and specific application, electrical cables can serve one or multiple functions:

- Power transmission: Carry low, medium, or high voltage electricity to machinery, production equipment, and building power systems.

- Control signal transmission: Connect sensors and PLCs to ensure accurate and synchronized operation.

- Data and communication transmission: Network cables, fiber optic cables, and communication cables enable efficient operation of automation systems.

- Measurement signal transmission: Signal cables from temperature, pressure, and flow sensors ensure accurate and stable data.

- Safety and protection: Grounding wires, shielded cables, and fire-resistant cables help minimize electrical shock hazards, prevent fire risks, and maintain operation under emergency conditions.

- Motor control: Power and servo cables deliver power and control signals to motors and frequency inverters, requiring vibration resistance and EMC protection.

- Specialized applications: Rodent-resistant cables, chemical-resistant cables, outdoor-rated cables, and drag chain cables designed for harsh industrial environments.

Some electrical cables from HELUKABEL

2.3 Classification of electrical cables

Compared with wires, electrical cables are more diverse and classified based on multiple criteria. Some common classification methods include:

- By conductor material: Copper cables, aluminum cables, tinned copper cables, Class 5 flexible cables…

- By insulation and outer sheath materials: PVC, PUR, TPE, XLPE, rubber, silicone...

- By application: Control cables, data cables, fiber optic cables, audio cables, Ethernet network cables, reeling cables, servo motor cables, heat-resistant cables…

- By properties: Fire-resistant cables, flame-retardant cables, direct-burial cables, oil-resistant cables, chemical-resistant cables.

- By voltage rating: 0.6/1kV, 300/500V, 450/750V, 18/30kV…

- Other criteria: Number of cores (single-core, multi-core), cable structures (CV, CVV, CXV), and compliance with standards (IEC, DIN VDE, ECOLAB, UL/CSA).

3. Comparing electrical wires and cables

3.1 Similarities

The fundamental similarity between electrical cables and electrical wires is their ability to conduct electricity. Structurally, a wire is essentially the building block of a cable — a cable is formed by bundling multiple wires together.

Both wires and cables can be insulated. However, in cables, each individual conductor is insulated, and the entire cable is further protected by an outer sheath.

This difference in insulation structure leads to different usage purposes in electrical and industrial applications.

3.2 Differences between cables and wires

| Wires | Cables | |

| Structure | Consist of a single conductor. Wires are typically more flexible and easier to install in tight spaces | Composed of multiple conductor cores bundled, twisted, or stranded together. More robust structure but heavier and less flexible due to additional insulation and protective layers. |

| Functions | Used for short electrical connections and basic current transmission | Suitable for more complex systems requiring durability, long-distance power transmission, and integrated control or data transfer |

| Applications | Residential wiring and small household electronic devices | Communication networks Automated control, industrial use |

| Classifications | Two main types: solid wire and stranded wire | Highly diversified, suitable for different operating conditions |

| Flexibility | More flexible due to simpler construction, but less durable and more prone to damage in harsh environments | Equipped with many protective layers, offering superior durability |

| Cost | Lower cost due to simple structure and fewer protective components | Higher cost but delivers better long-term value |

3.3 When should you use electrical wires vs. electrical cables?

Choosing between a wire and a cable depends on several practical factors such as installation type, voltage level, mechanical stress, and environmental conditions.

- Use electrical wires for short distances or when only a single conductor is required. Examples: indoor lighting circuits, outlets, and small household appliances.

- Use electrical cables when transmitting power over longer distances, requiring multiple conductors, or operating in demanding environments. Examples: network infrastructure, industrial equipment, control systems, underground or concealed installations requiring enhanced safety.

For accurate product selection tailored to your specific application requirements, please contact the HELUKABEL team for technical consultation.

4. HELUKABEL’s electrical cable and wire portfolio

HELUPOWER® CU-CONDUCTOR-CL5 TINNED

Whether electrical wires or cables, HELUKABEL offers a comprehensive connectivity solution for industrial applications with a catalog of more than 33,000 product items.

We provide a full range of bare copper conductors specifically designed for grounding and earthing applications, available in multiple configurations:

- Round single conductor, bare copper or tinned copper, from Class 2 to Class 6/7

- Round stranded conductor, bare copper or tinned copper, from Class 6/4 to Class 6/7

For industrial electrical cables, our products cover:

- General-purpose applications: Control cables, instrumentation cables, audio signal cables, DC solar cables…

- High mechanical stress applications: Cables for drag chains, robot cables, and reeling operations

- Harsh and demanding industrial environments: Fire-resistant and flame-retardant cables, cables for oil & gas industries, hazardous areas (Ex zones), and chemical-resistant cables

- Customized cabling solutions tailored to customer specifications

If you still have questions, don't hesitate to contact HELUKABEL Vietnam's team of engineers for detailed answers.

HELUKABEL® Vietnam

| Address | 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000 |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover and purchase our products on | Tiki | Shopee | Lazada | Product finder |

| Connect with us on | Facebook | LinkedIn | Instagram | YouTube | Zalo | WhatsApp | TikTok | Spotify |