HELUCHAIN® MULTISPEED® - Drag chain cables for highly dynamic applications

HELUCHAIN® MULTISPEED® is a cable series specifically designed for high loads conditions and millions of movement cycles. Its diverse range of sheath materials and conductor cross-sections, advanced pressure-extrusion technology, and smart integrated ripcord design are key advantages of this product line.

1. Overview of the HELUCHAIN® MULTISPEED® cable

HELUCHAIN® MULTISPEED® is specifically designed for drag chains, available in three sheath versions: PVC, PUR, and TPE

The HELUCHAIN® MULTISPEED® cable line is specially designed for cable chain applications with high dynamic movement. The control cables, connection cables, and motor cables in this line feature multiple conductor cross-sections, three different sheath materials, and both shielded and unshielded versions—offering the optimal choice for every application.

In order to customize these drag chain cables perfectly for each application, customers have the choice between three different sheath materials:

- PVC: resistant to water, acids, and cleaning agents and is economically priced.

- PUR: oil resistant, notch resistant, and well suited for long travel distances and quick accelerations.

- TPE: light, resilient, for tight bending radii, low temperatures, and outdoor and heavy-duty applications

All cables are also available in variants with tinned-copper, braided screen, which improves their EMC qualities.

2. Outstanding benefits of HELUCHAIN MULTISPEED drag chain cables

2.1 Long service life with improved bending cycles

The HELUCHAIN® MULTISPEED® cable range stands out for its exceptional lifespan in drag chain systems, even under highly demanding movements and millions of bending cycles.

The HELUCHAIN MULTISPEED cables are all constructed according to the same principle and are optimized for continuously moving applications in drag chains. A gusset-filling, extruded sheath ensures that the individual cores are stable and prevents mechanical damage through abrasion or bending, especially with long travel distances. Cable variations with seven cores or more are stranded in bundles to equally distribute forces. This results in a significantly improved lifespan, even with demanding movements and millions of bending cycles.

With the HELUCHAIN MULTISPEED cable line, the ripcord allows users to effortlessly expose the cores within to the desired length.

2.2 Easy cable stripping with ripcords

A highlight of the MULTISPEED series is its integrated ripcord, which makes it possible to effortlessly strip the cables without the need for special tools. A simple circumferential cut is enough to expose the cores in the desired length, making installation easier and saving time and money. This safe cable stripping technology even minimises the risk of damaging the cores, which could result in expensive disruptions and downtime.

Specialized cable for HELUCHAIN® MULTISPEED® 600-C-TPE-J cable chain, single-core version

2.3 Available in various cross-sections and core-counts

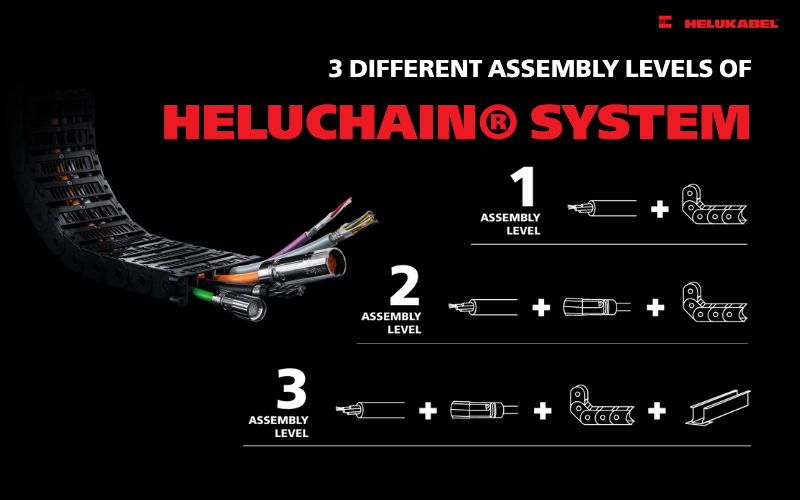

The HELUCHAIN MULTISPEED cables are available ex stock in a large number of cross-sections and core-counts. All cables from this series have UL and CSA approvals, meaning export-oriented mechanical and plant engineers can use these internationally, avoid double inventory, and simplify documentation. On request, HELUKABEL will assemble the cables with the required plugs and, as a systems supplier, also supplies complete, pre-installed and installation-ready, steel, stainless-steel, and plastic drag chains—from custom-designed solutions to series products.

3. HELUCHAIN® MULTISPEED® drag chain cable portfolio

3.1 HELUCHAIN® MULTISPEED® cables – PVC variants

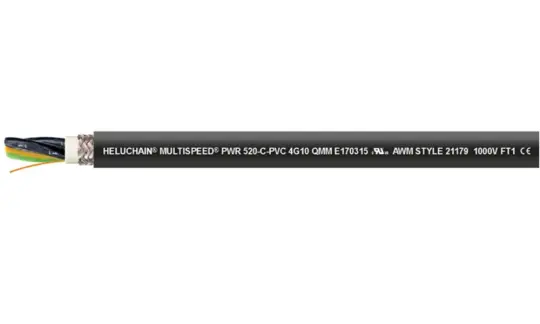

The HELUCHAIN® MULTISPEED® cables with PVC outer sheaths are manufactured from high-quality PVC materials that meet stringent mechanical and durability requirements. The outer sheath is pressure-extruded to completely fill the gussets, ensuring that the conductors are guided longitudinally. This construction makes the entire cable more robust, especially for long travel distances or tight bending radii.

These characteristics make the PVC version ideal for applications with standard travel lengths and high acceleration, such as indoor cranes, handling and packaging stations, and rack feeders.

| Cable | Cross-sectional area (mm²) | Bending factor | Maximum travel distance (m) | Part number |

| HELUCHAIN® MULTISPEED® 520-PVC UL/CSA | 0.5 – 6 | 6.8 | 100 | 11001528 |

| HELUCHAIN® MULTISPEED® 520-C-PVC UL/CSA | 0.5 - 6 | 6.8 | 100 | 11001602 |

| HELUCHAIN® MULTISPEED® PWR 520-PVC UL/CSA | 10 -35 | 7.5 | 100 | 11001592 |

| HELUCHAIN® MULTISPEED® PWR 520-C-PVC UL/CSA | 10 - 35 | 7.5 | 100 | 11001666 |

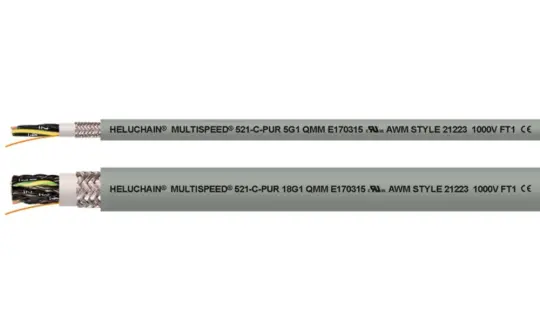

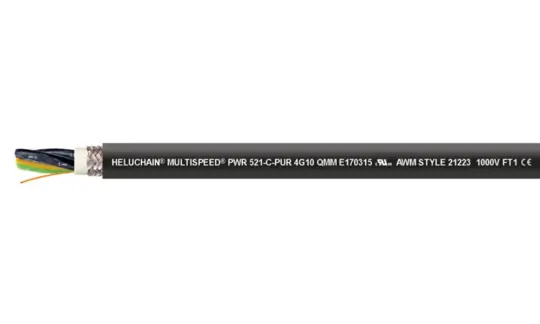

3.2 HELUCHAIN® MULTISPEED® cables – PUR variants

The outer sheath is made from a PUR material that offers excellent abrasion resistance against the components of the drag chain. This enhances durability in real-world applications and reduces the amount of abrasion particles generated during operation.

With advantages such as long travel distances, high acceleration capabilities, and strong oil resistance, the HELUCHAIN® MULTISPEED® PUR version is particularly suitable for applications such as machining/machine tools and packaging systems.

| Cable | Cross-sectional area (mm²) | Bending factor | Maximum travel distance (m) | Part number |

| HELUCHAIN® MULTISPEED® 521-PUR UL/CSA | 0.5 – 6 | 6.8 | 450 | 11001676 |

| HELUCHAIN® MULTISPEED® 521-C-PUR UL/CSA | 0.5 - 6 | 6.8 | 450 | 11001750 |

| HELUCHAIN® MULTISPEED® PWR 521-PUR UL/CSA | 10 -35 | 7.5 | 450 | 11001740 |

| HELUCHAIN® MULTISPEED® PWR 521-C-PUR UL/CSA | 10 - 35 | 7.5 | 450 | 11001814 |

3.3 HELUCHAIN® MULTISPEED® cables – TPE variants

The outer sheath compound is made from a TPE material that provides excellent abrasion resistance against the components of the drag chain. This increases durability in real-world applications and reduces abrasion particles during operation.

The TPE version of the HELUCHAIN® MULTISPEED® cable series is ideal for heavy-duty applications, including long travel distances, small bending radii, numerous bending cycles, low temperatures, and outdoor installations. Typical applications include steel plants, cranes, mining operations, semiconductor assembly, and stacking systems.

| Cable | Cross-sectional area (mm²) | Bending factor | Maximum travel distance (m) | Part number |

| HELUCHAIN® MULTISPEED® 522-TPE UL/CSA | 0.5 – 6 | 5 | 450 | 11001824 |

| HELUCHAIN® MULTISPEED® 522-C-TPE UL/CSA | 0.5 - 6 | 5 | 450 | 11001898 |

| HELUCHAIN® MULTISPEED® PWR 522-TPE UL/CSA | 10 -35 | 7.5 | 450 | 11001888 |

| HELUCHAIN® MULTISPEED® PWR 522-C-TPE UL/CSA | 10 - 35 | 7.5 | 450 | 11001962 |

| HELUCHAIN® MULTISPEED® 600(-C)-TPE (single core cable) | 6 - 185 | 5 | 450 | 11026311 |

If you still have questions, don't hesitate to contact HELUKABEL Vietnam's team of engineers for detailed answers.

HELUKABEL® Vietnam

| Address | 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000 |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover and purchase our products on | Tiki | Shopee | Lazada | Product finder |

| Connect with us on | Facebook | LinkedIn | Instagram | YouTube | Zalo | WhatsApp | TikTok | Spotify |