HELUKABEL flexible cables – Durable solutions for continuous motion applications

What technical features make flexible cables suitable for continuous motion applications? Discover the answer in this article!

In many electrical projects – from automated production lines and industrial robots to factory cabinet systems – selecting the right cable involves more than just voltage rating or conductor size. Cable flexibility is the hidden factor that determines both ease of installation and long-term service life. Some cables only need to be bent once during installation, while continuous motion applications demand specialized cables capable of withstanding thousands of bending, twisting, and tensile cycles.

This article will help you clearly understand the different levels of flexibility, how to distinguish them, and the key criteria for choosing the right cable. With the right selection, you can prevent failures and optimize maintenance costs.

1. Distinguish between the flexibility and softness of electrical cables

Flexibility is the ability of an electrical cable to bend, twist, or change shape at a given point without causing damage.

Flexibility and softness are two mechanical properties of electrical cables that are often confused.

1.1 Flexibility

Flexibility refers to a cable’s ability to bend, twist, or change shape at a given moment without causing damage to the conductor, insulation, or outer sheath. This characteristic indicates how well a cable can withstand movement, bending, or routing around complex structures during installation or operation.

Flexibility is typically evaluated through the minimum bending radius – the smallest radius a cable can be bent without compromising its electrical or mechanical performance. The bending radius depends on several factors, including the cable’s outer diameter, conductor structure (number of strands, strand diameter), and the type of insulation or sheath material.

In other words, a highly flexible cable can bend easily and maintain its bent shape without cracking the sheath, breaking conductor strands, or degrading its electrical/data transmission properties.

The softness of the electrical core is divided into different levels (classes).

1.2 Softness of the conductor

Softness describes the degree of flexibility and ease of bending of the metal conductor itself – the part inside the cable responsible for electrical conduction. It reflects how well the conductor can withstand manual bending and shaping during installation without cracking or reducing its conductive cross-section.

Unlike flexibility, which considers the entire cable structure and its ability to endure long-term dynamic motion, softness focuses only on the conductor’s pliability. A softer conductor makes it easier to route cables in tight spaces while maintaining stable conductivity.

According to IEC 60228, conductor softness is classified into different classes:

- Class 1: Solid conductor (single wire), used in fixed/static applications.

- Class 2: Stranded conductor with a few wires (typically 7), used in low-vibration applications.

- Class 5: Flexible conductor with many fine strands, used in applications requiring free movement without strong tensile forces.

- Class 6: Extra-flexible conductor with very fine strands, used in drag chain systems or robotic applications.

The higher the level, the higher the softness of the conductive core.

2. What are flexible cables?

Flexible cables are easy to handle and install in typical applications such as cable trays.

2.1 Flexible installation cables (Flexible cables)

Flexible installation cables, often referred to in technical documents, are mainly evaluated based on their ability to bend easily and allow convenient handling during installation. These cables are ideal for routing around complex structures or for twisting to achieve a more aesthetic installation.

Once installed, these cables typically remain static, meaning flex life (the number of bending cycles a cable can withstand) is not a critical factor. Typical applications include cable trays, fixed wiring systems, household appliance connections, static industrial systems.

Continuous-flex cables are specialized cables for continuous motion applications such as cable chains.

2.2 Dynamic flexible cable (Flex cables)

Dynamic flexible cables, also known simply as flex cables, are specifically engineered to endure repeated bending, twisting, and continuous movement while maintaining mechanical integrity and transmission performance. They are the optimal choice for continuously operating systems where conventional rigid cables would quickly degrade or fail.

Key features of flex cables:

- High flexibility: Capable of withstanding millions of bending cycles at very small radii without cracking the insulation or breaking the conductor.

- High durability: Optimized construction resists abrasion, vibration, and mechanical stress caused by continuous movement. Ideal for robotic arms, drag chain systems, automated conveyors, handheld devices, and machinery requiring frequent motion.

- Lightweight with finely stranded conductors: Built with ultra-fine copper strands, making the cable thinner, lighter, and easier to route compared to rigid cables.

3. Flexible cables and influencing factors

The wire braiding process at our Windsbach factory

The ability of a flexible cable to bend, twist, and withstand continuous movement is primarily determined by the construction of its internal components. Each element - from the conductor to the outer sheath - directly impacts the cable’s overall flexibility.

3.1 Conductor – the most important factor

The flexibility of a cable originates mainly from the design and stranding technique of the conductor. By bunching many ultra-fine copper wires into strands, the cable achieves both greater pliability and a longer flex life, ensuring consistent electrical and mechanical performance throughout its service life.

Flexible cables typically use class 5 or class 6 stranded copper conductors as defined by IEC 60228, instead of class 1 or 2. The reason is that class 5 and class 6 conductors consist of a high number of fine copper strands twisted together. The smaller the strand diameter, the higher the cable’s bending capability and vibration resistance. This makes class 5 and 6 conductors ideal for robotics, conveyor systems, drag chains, and mobile equipment.

3.2 Outer sheath materials

The outer sheath of a cable not only protects the conductor but also plays a critical role in determining its flexibility, handling properties, and bending lifespan. However, the softest sheath material does not necessarily guarantee the longest flex life. Several material properties directly influence the performance of flexible cables:

- Hardness: Impacts bending ability and elasticity.

- Tear strength: Prevents cracks and tears under repeated bending or handling.

- Tensile strength and elongation: Ensures the sheath resists deformation or breakage under mechanical stress.

- Coefficient of friction: Affects sliding performance when the cable moves inside conduits, trays, or drag chains.

For example, rigid polymers such as XLPE, HDPE, or standard PVC provide excellent resistance to heat and chemicals but make the cable stiffer, reducing flexibility and ease of installation in confined spaces. Conversely, specialized elastomeric materials like EPR rubber allow the cable to bend more easily, ensuring high flexibility while maintaining reliable insulation and durability in industrial environments.

The shielding process at the HELUKABEL production plant

3.3 Armour and shield

The armour and shield are critical supplementary components in cables, providing protection against mechanical stress and electromagnetic interference (EMI). However, these layers also have a direct impact on the flexibility and bending performance of flexible cables.

For example, galvanized steel wire (GSW) armor offers strong mechanical protection but significantly increases cable stiffness, reducing its overall flexibility.

In flexible cables requiring EMI protection, a tinned copper braid shield (with coverage up to 85%) is commonly used because it maintains cable pliability while still providing effective shielding. In contrast, an aluminum foil shield delivers 100% coverage but comes with the drawback of reduced bending radius and limited flexibility.

4. Comparison of flexible cables and rigid cables

4.1 What are rigid cables?

Rigid cables, also referred to as conventional cables, are primarily designed for static stability and fixed installations. They are suitable for environments where the cable is not subject to repeated bending, twisting, or movement.

Key advantages:

- Robust construction: Solid conductors with thick insulation and protective layers provide high mechanical strength.

- Cost-effective: Made from common materials with simple manufacturing processes, rigid cables are generally more economical than flexible cables.

- Stable power transmission: Reliable long-term performance with minimal mechanical stress impact.

4.2 Flexible cables vs. rigid cables

| Criteria | Flexible cables | Rigid cables |

| Construction | Finely stranded conductors, optimized for bending and movement | Solid conductor, thick insulation and sheath, prioritizing mechanical stability |

| Performance | High flexibility, torsion resistance, withstands continuous motion | High mechanical strength, good compression resistance, but poor flexibility – not suitable for dynamic environments |

| Cost | Higher due to specialized materials and complex manufacturing processes | Lower, made from common materials with simple production methods |

| Applications | Robots, automated production lines, drag chains, mobile equipment | Building wiring, fixed power lines, static transmission systems |

| Life cycle | Dependent on flex cycles and degree of movement | Long-lasting in static environments, unaffected by repeated bending |

| Installation and maintenance | Easy to route in complex spaces, requires compliance with minimum bending radius | Installed in fixed positions, maintenance focuses on insulation aging and connection points |

The choice between flexible cables and rigid cables is not based on absolute advantages, but rather on the specific application requirements and operating conditions. Key factors to consider include the degree of movement, mechanical stress, operating environment, and cost. Neither cable type is universally superior; the most important aspect is selecting the solution that best fits the needs of each specific application.

5. Applications of flexible cables

Continuous-flex cables ideal for applications requiring frequent bending and movement

5.1 When should flexible cables be used?

Flexible cables are ideal for applications that require frequent bending and movement. They ensure stable transmission of power and signals while withstanding continuous motion without reducing service life or performance. Key applications include:

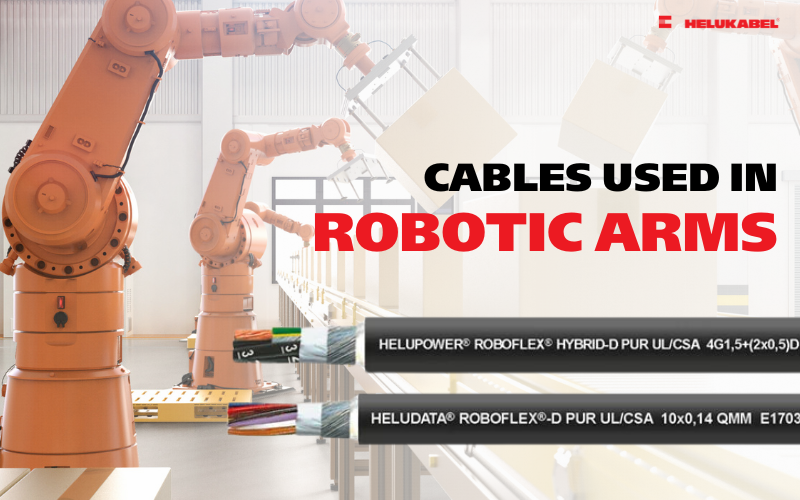

- Industrial automation: Automatic machinery, production lines, conveyors, and robotic arms - ensuring stable power and signal transmission in high-vibration environments.

- Robotics: Supporting complex, repetitive, and multidirectional movements, helping extend equipment lifespan and maintain precise functionality.

- Audio, video, and studio equipment: Microphones, musical instruments, speakers, and cameras - ensuring signal integrity while minimizing wear and tear during frequent handling.

- Renewable energy: Wind turbines and solar panels - withstanding outdoor conditions and adapting to the movement of blades or solar modules.

For specialized applications, prioritize the use of specialized cables (fire-resistant, hazardous areas, etc.).

5.2 When are continuous-flex cables not the optimal choice?

Although flexible cables are highly advantageous for dynamic applications, there are certain scenarios where they may not be suitable because they cannot meet the required mechanical, electrical, or safety standards:

- Fixed wiring systems: Not recommended, as flexible cables may not comply with electrical standards and installation codes.

- High-stress or extreme temperature environments: Flexible cables are limited in scenarios with heavy mechanical loads or extreme heat/cold.

- Heavy-load applications: Long-term tensile or compressive forces can cause abrasion, damage, or breakage that exceeds the durability of standard flexible cables.

- Fire-resistance requirements: In environments where fire protection is critical, flexible cables may not always provide sufficient resistance. Specialized fire-resistant cables are a more reliable solution.

6. HELUKABEL flexible cables for continuous motion applications

HELUKABEL offers a wide range of flexible cable solutions with finely stranded (Class 5) and ultra-finely stranded (Class 6) conductors. These cables are engineered to meet the demanding requirements of continuous motion and repetitive bending in industrial automation, robotics, and other specialized applications.

Depending on the type of movement and operating environment, HELUKABEL flexible cables are categorized into five main groups:

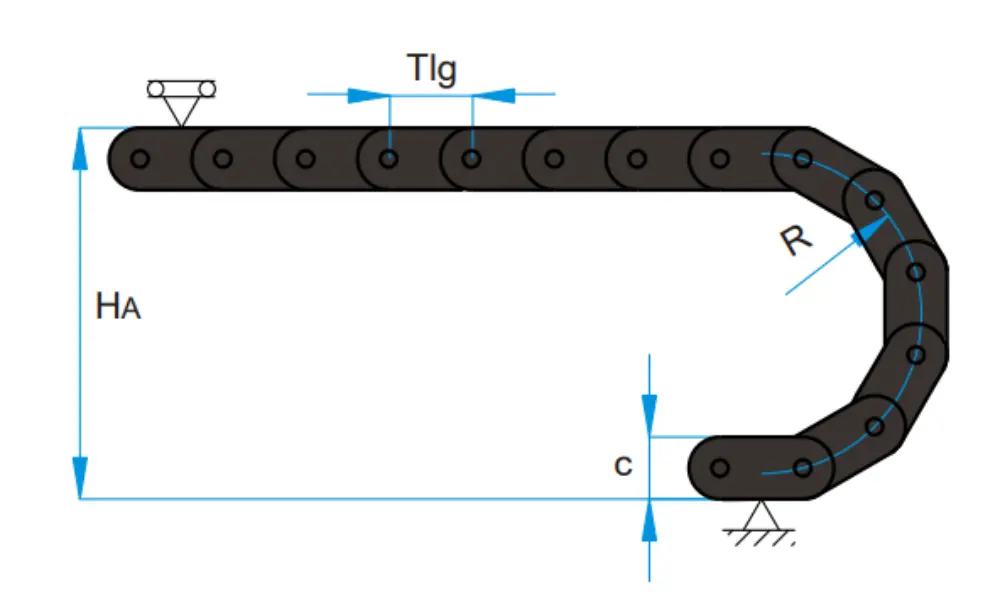

6.1 Flexible cables for drag chains

These cables are specifically designed to withstand continuous bending stresses within drag chain systems. With ultra-fine stranded conductors, abrasion-resistant insulation, and durable outer sheath, this product line ensures high flexibility while maintaining mechanical strength and long service life.

| Cable products | Bending factors | Key features |

| MULTIFLEX 512®-PUR UL/CSA | 5 | For applications with extremely high mechanical stress |

| MULTISPEED® PWR 520-C-PVC UL/CSA | 7.5 | Oil-resistant, For applications with extremely high mechanical stress |

| TOPGEBER® 512 PUR | 10 | Cables for cable chains used in Siemens, Bosch Rexroth, and Lenze systems |

| HELUKAT® 500S CAT.6A | 10 | Halogen-free, flame-retardant |

| HELUCHAIN® SINGLE 602-HF-CY-J PVC UL/CSA | 7.5 | Single-core PVC cable, for applications with frequent lifting and bending stresses |

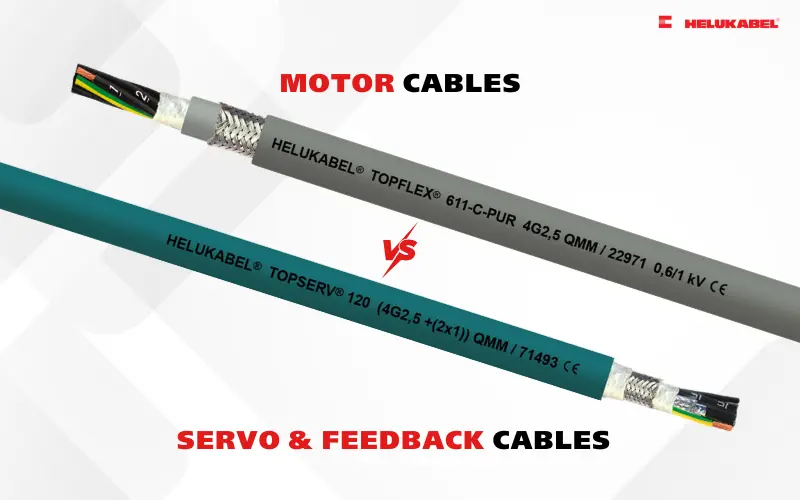

6.2 Torsion-resistant cables for robotic applications

Torsional flex cables are specifically engineered to withstand twisting loads in applications where the cable rotates repeatedly around its own axis. The use of finely stranded conductors combined with a highly elastic, specially formulated outer jacket ensures that the cable maintains both mechanical integrity and electrical performance over an extended service life.

| Cable products | Bending factors | Minimum bending cycle |

| HELUDATA® ROBOFLEX® PUR UL/CSA | 10 | 10 million |

| HELUCONTROL® ROBOFLEX®-D PUR UL/CSA | 10 | 5 million |

| HELUPOWER® ROBOFLEX® HYBRID-D PUR UL/CSA | 10 | 10 million |

| HELUDATA® ROBOFLEX®-recycle PUR UL/CSA | 10 | 10 million |

| A-V(ZN)11Y Fiber Optic Cable | 75–105 mm | 500,000 |

6.3. Reeling cables

Reeling cables are specifically designed to withstand high mechanical loads and continuous bending. Their outer sheath is made from special materials that reduce friction, resist abrasion, and endure harsh operating environments. These cables are widely used in lifting equipment, pulley systems, mobile industrial stations, and other applications requiring continuous winding and unwinding.

Some notable reeling cable lines include: NSHTÖU , (N)SHTÖU-V , TROMMPUR®-H

6.4 Flat cables

Flat cables feature a thin, flat design that makes them easy to install in confined spaces or narrow slots. With a special conductor configuration and braided structure, they provide sufficient flexibility, torsion resistance, and abrasion resistance. They are ideal for use in industrial robots, conveyor systems, mobile equipment, as well as portable audio-visual systems.

6.5. Lift/elevator cables

Lift/elevator cables are designed to withstand continuous tensile and bending stress during lifting operations, while also offering resistance to abrasion and signal interference. Their outer sheath is made from specially engineered materials to ensure high performance and long service life in elevator environments or automated building hoisting systems.

Some HELUKABEL cable lines for this application include: PVC-flat, PVC-flach-CY, NEO-flach, NEO-flach-C, TRAGO / Lift-2S, LIFT-TRAGO®-30 / -60, NEOPREN

If you still have questions, don't hesitate to contact HELUKABEL Vietnam's team of engineers for detailed answers.

HELUKABEL® Vietnam

| Address | 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000 |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover and purchase our products on | Tiki | Shopee | Lazada | Product finder |

| Connect with us on | Facebook | LinkedIn | Instagram | YouTube | Zalo | WhatsApp | TikTok | Spotify |