What are control cables? Structure and classifications of control cables

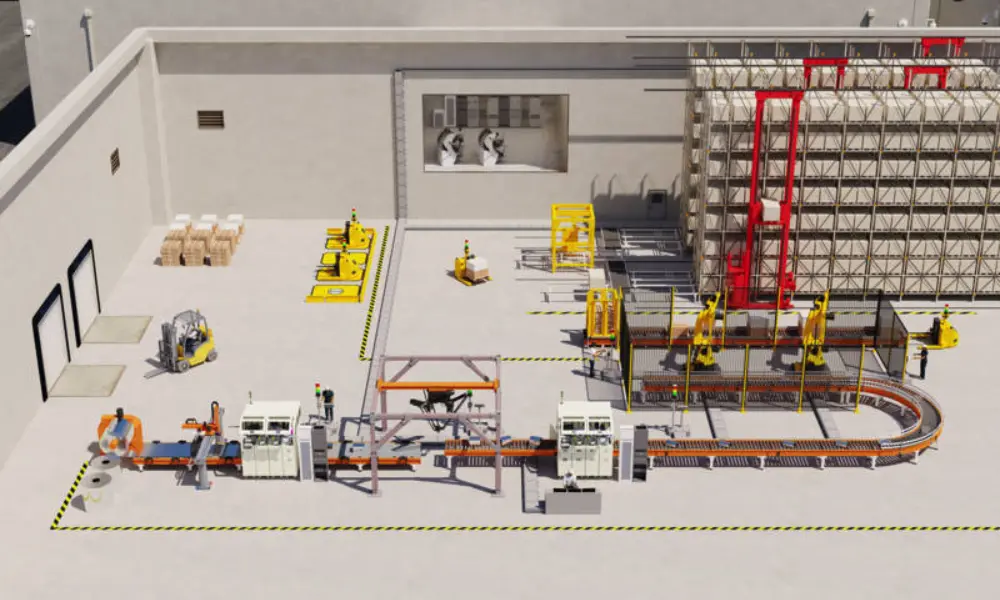

Control cables are indispensable components in countless systems, enabling precise signal transmission and communication across various industries. From production lines to infrastructure and construction sectors, these cables ensure that machinery operates smoothly, safely, and efficiently.

1. Overview of control cables

1.1 What are control cables?

Control cables are specialized electrical cables designed to transmit control signals to machinery and electronic systems. They are used for both internal and external wiring, connecting equipment ranging from machines and production lines to sensors and actuators. Control signals instruct the receiving device to perform specific functions.

Serving as the communication link between sensors, switches, controllers, and operating devices, control cables enable automation systems to react and adjust in real time. As industries move toward smarter and more connected operations, control cables are evolving to support higher data transmission rates and greater durability.

These cables are engineered to withstand harsh environmental conditions such as extreme temperatures, humidity, and mechanical stress. They are widely used in industrial automation, robotics, transportation, and building management systems. Their construction ensures stable signal transmission, high safety, and compliance with industry standards.

The role of control cables continues to grow in importance as they ensure uninterrupted communication, minimize interference, and maintain smooth operation in complex industrial environments.

_post_detail_picture-2.png)

1.2 Basic structure of control cables

The construction of a control cable typically consists of the following components: conductor, insulation, shielding, outer sheath, and armor.

- Conductor: The most critical part of the cable, commonly made of copper or aluminum. Depending on the application, it may be a single-core or multi-core structure.

- Insulation: Provides electrical isolation between the conductors and from the external environment. Common insulation materials include PVC and XLPE.

- Shielding: Protects against EMI from external sources and prevents emitted interference from affecting surrounding equipment. Common shielding materials include: Cu braid, Cu tape, Alu-PET foil

- Outer sheath: Protects the cable from mechanical impact, chemical, and environmental factors. Frequently used materials include PVC, rubber, or PUR depending on the application conditions.

- Armour: Enhances mechanical strength, impact resistance, and external force protection. Typically made from steel tape or steel wire, depending on the required durability.

2. Applications of control cables

Control cables play a crucial role in most systems that require high levels of accuracy and safety. Below are the most common application sectors:

Industrial automation: From production lines to robotic systems, control cables connect sensors, motors, and PLCs to ensure every movement occurs at the right time. They are designed to withstand continuous motion, vibration, and electromagnetic interference.

Building Management Systems (BMS) and construction: In both commercial and residential buildings, control cables are used for lighting control, elevators, HVAC systems, and fire alarm systems. They help maintain stable operation and ensure the safety of facilities.

Internal wiring of machinery and equipment: Inside machinery such as CNC machines, conveyors, and packaging equipment, control cables manage functions like start/stop, speed control, or emergency shutdown. Highly flexible cables are used when components are subject to frequent motion.

Renewable energy: Control cables play an essential role in solar farms and wind turbines by connecting sensors, controllers, and power converters. They support real-time monitoring, precise adjustments, and overall system optimization. For example: Offshore wind farms require durable control cables capable of withstanding harsh marine environments to ensure continuous operation and compliance with safety standards.

3. Differentiating control cables from other common electrical cables

There are several types of electrical cables that are closely associated with control cables and sometimes used interchangeably. However, distinct differences exist between them.

3.1 Control vs signal vs instrumentation cables

Signal cables: include coaxial cables, twisted pair cables, and fiber optic cables. They are primarily used for data transmission, so they require shielding to protect against EMI.

Control cables: Similar to signal cables, control cables also carry control signals. However, they are not always shielded. They are mainly used to transmit command signals to devices within automation systems.

Instrumentation cables: Designed for transmitting measurement and monitoring signals, these cables require superior shielding against EMI and crosstalk.

In many cases, the terms “control cable” and “instrumentation cable” may be used interchangeably, as their functions are closely related.

Power cables are commonly used in infrastructure and construction.

3.2 Control cables vs power cables

Power cables are responsible for transmitting electrical energy in machinery, industrial facilities, and equipment. They are also used to supply power to buildings and to distribute electricity in power plants and substations. This type of cable may also be called connection cable, supply cable, or energy cable.

Although both power and control cables are widely used in industrial, commercial, and residential environments, they differ significantly:

Operating voltage: Power cables typically handle higher voltages, starting from 0.6/1 kV and above, while control cables operate at lower voltage levels, usually 300/450/600/750 V.

Insulation: Because power cables transmit high energy loads, they require strong and durable jackets that can withstand corrosion, temperature changes, and harsh external conditions. Control cables, on the other hand, generally do not need such heavy-duty sheathing and commonly use standard PVC insulation.

4. Classification of HELUKABEL control cables

With a wide range of applications, control cables are often exposed to various challenges such as continuous movement, mechanical stress, tensile load, bending, and torsion. Therefore, they must be both flexible and durable, while also resisting harsh environmental conditions including oil, chemicals, weather, and UV exposure.

HELUKABEL's control cable portfolio is designed to overcome these challenges, offering diverse options in conductor cross section, number of cores, properties, technical parameters, and international standards. In addition, we provide customized solutions to best meet specific operational requirements.

JZ-604 TC TRAY CABLE PVC-sheathed control cable

4.1 PVC control cables

PVC control cables are the most common choice for general industrial applications.

Properties: Flexible, easy to install, cost-effective.

Applications: Suitable for dry indoor environments, commonly used in standard industrial production lines.

Advantages: Operating temperature range from approx. -30°C to +70°C, excellent electrical insulation, and moderate mechanical strength.

| PVC control cable | Cross-sectional area (mm²) | Characteristics | Part number |

| JZ-500 | 0.5 – 185 | Oil-resistant, conditionally torsion | 10001 |

| F-CY-JZ | 0.5 - 50 | 2 types of screening: helically wound tinned copper wires and braided screen of tinned copper wire | 16320 |

| Y-CY-JZ / Y-CY-OZ | 0.5 – 150 | Transparent outer sheath, with inner sheath for increased mechanical protection | 16200 |

| JZ-604 TC Cable Tray | 1 - 185 | Direct burial, TC-ER (exposed run), NFPA 79, +90°C | 69661 |

PUR-YELLOW control cable

4.2 PUR and TPE control cables

PUR and TPE control cables are well-known for their exceptional flexibility and high elasticity.

Properties: Highly flexible, abrasion resistance, resistant to oils, chemicals, and weather conditions.

Applications: Ideal for dynamic applications such as robotic systems, drag chain, and outdoor environments.

Advantages: Outstanding tear resistance, long service life under harsh operating conditions, UV resistance, and wide operating temperature ranges: -55°C to +80°C (PUR), -50°C to +100°C (TPE).

HELUPOWER® 1100-RZ1-K LS0H GREEN control cable

4.3 Halogen-free control cables

Properties: Halogen-free material, reducing smoke and toxic gas emissions in event of fire.

Applications: Suitable for buildings and facilities requiring a high level of fire safety, such as steel plants, metallurgy

Advantages: Enhanced safety for people and equipment, flame-retardant, and maintains solid mechanical performance.

| Halogen-free control cable | Cross-sectional area (mm²) | Characteristics | Part number |

| JZ-500 HMH | 0.5 - 120 | High flame retardancy | 11201 |

| JZ-600 HMH | 0.5 - 120 | 0.6/1 kV, highly flame-retardant | 12723 |

| HELUCONTROL® JZ-520-HMH LS0H GREY | 0.5 - 10 | B2ca CPR, highly flame-retardant | 11008617 |

| HELUPOWER® 1100-RZ1-K LS0H GREEN | 1.5 - 300 | Flexible, can be buried directly | 11008092 |

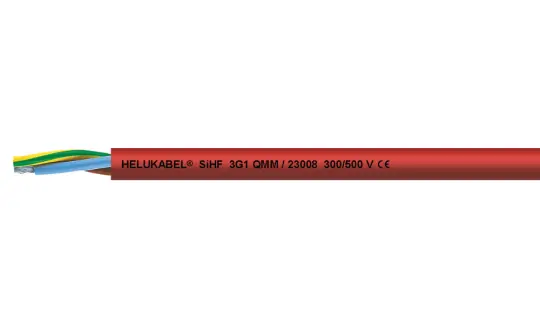

4.4 Silicone control cables

Silicone is one of the best temperature-resistant materials, offering outstanding performance in both high and low temperature environments.

Properties: Highly flexible even under extreme temperatures; resilient against harsh environmental conditions.

Applications: Ideal for high-temperature equipment, specialized machinery, and industries such as food processing and medical technology.

Advantages: Wide operating temperature range from -60°C to +180°C, good mechanical strength.

4.5 Rubber control cables

Rubber control cables are among the most durable and flexible cable types, making them highly suitable for heavy-duty industrial applications.

Properties: Soft, flexible, and excellent mechanical strength.

Applications: Designed for environments with impact and vibration, industrial festoon systems, and heavy machinery.

Advantages: Strong abrasion and tensile resistance; operating temperature typically ranges from -30°C to +90°C (depending on the rubber compound).

| Rubber control cable | Cross-sectional area (mm²) | Characteristics | Part number |

| H07RN-F / 07RN-F | 1 -500 | Oil-resistant, weather-resistant | 37001 |

| National Science and Technology Higher Education | 1.5 – 240 | For high mechanical stress applications in heavy-duty industries | 38001 |

| HELUPOWER® SJOOW | 10–18 AWG | Water-resistant, for Class 1 Div. 2 explosive environments acc. to NEC Art. 501 | 11131802 |

Intrinsically safe control cables are usually green.

4.6 Intrinsically Safe control cables

Intrinsic safety is a protection technique designed to ensure the safe operation of electrical and electronic equipment in hazardous areas, where any potential ignition source must be completely eliminated.

Essentially, electrical cables with a sealed construction can be considered intrinsically safe in certain applications if they are protected against mechanical damage, external electrical or magnetic fields (EMI), and isolated from non-intrinsically safe circuits. Junctions and switches represent potential ignition points in these environments and circuits.

Intrinsically safe control cables are typically blue to identify potential electrical hazards and the need for special handling measures. HELUKABEL's three intrinsically safe cable products include: OZ-BL ( 14001 ), OZ-BL-CY ( 14028 ), OB-BL-PAAR-CY ( 14077 ).

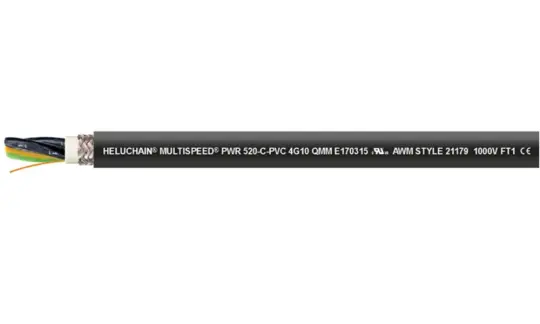

4.7 Control cables for drag chains and continuous moving applications

For drag chains and dynamic applications, HELUKABEL offers specialized cable series designed to withstand the high mechanical loads, continuous bending cycles, and torsion these applications typically encounter.

Download the HELUCHAIN® MULTISPEED® cable catalog from HELUKABEL

| Cables | Cross-sectional area (mm²) | Characteristics | Part number |

| HELUCHAIN® MULTISPEED® | 0.5 – 6 10 - 35 | Available in PVC, PUR, TPE version, suitable for different operating environment of drag chains |

11001666 11001750 11001962 |

| PUR-JZ-HF | 0.5 - 95 | Oil-resistant, extremely robust drag chain cable | 15520 |

| HELUCONTROL® ROBOFLEX®-D PUR UL/CSA; HELUCONTROL® ROBOFLEX® 2001-D | 0.5 – 1.5 | For robotic applications with millions of bending cycles |

11022437 25497 |

4.8 HAR control cables

Harmonized European cables, commonly known as HAR cables, are cable types that comply with the Harmonization Document issued by CENELEC – the European Committee for Electrotechnical Standardization.

| HAR control cable | Cross-sectional area (mm²) | Characteristics | Part number |

| H05VV-F / 05VV-F | 0.75 - 4 | Available in grey, black, orange, white color | 29450 |

| H07BQ-F / 07BQ-F | 1.5 – 240 | Flexible in cold temperature -50°C | 22058 |

| H07ZZ-F | 1 - 500 | for heavy mechanical stress | 37176 |

| JZ-603-CY / OZ-603-CY | 0.5 – 2.5 | UL/CSA, EAC, HAR approval, suitable for export-oriented machine | 83709 |

4.9 UL/CSA control cables

The North American market (United States, Canada) plays a crucial role for many industries. Control cables certified by UL/CSA facilitate the import of equipment and machinery into these markets.

| UL/CSA control cable | Cross-sectional area (mm²) | Characteristics | Part number |

| TRAYCONTROL® 670 HDP | 1 - 35 | Bus Drop, TC-ER and CIC/TC approval Superior oil performance, for use in hazardous area acc. To Class I Div 2 per NEC 336, 318 and 501 | 66820 |

| MEGAFLEX® 600-C | 0.5 - 10 | Halogen-free, flame-retardant, UV-resistant, flexible | 15217 |

| JZ-604 TC Cable Tray / OZ-604 TC Cable Tray | 1 - 185 | TC-ER (exposed run), NFPA 79, +90°C | 69661 |

| HELUCONTROL® 2516 / 600-C GREY / HELUCONTROL® 2516 / 600-C BLACK | 12- 14 | UL Style 2516, 600 V, 105°C, EMC-preferred type | 83350 |

4.10 ECOLAB-certified control cables

ECOLAB® is an important standard for control cables used in environments with strict hygiene requirements, particularly in the F&B industry.

To meet the growing demand for control cables that meet strict hygiene standards, are antimicrobial, and prevent contamination, HELUKABEL offers a range of control cables certified to ECOLAB® standards , such as:

| Control cable meets ECOLAB standards | Cross-section | Characteristics | Part number |

| TRAYCONTROL® 500 / 500-C | 500 kcmil – 20 AWG | Oil Res I/II, exposed run: TC-ER, PLTC-ER, ITC-ER, NFPA 79 | 63,079 / 62,813 |

| TRAYCONTROL® 600 / 600-C | 500 kcmil – 20 AWG | Oil Res I/II, exposed run: TC-ER, PLTC-ER, ITC-ER, NFPA 79 | 62020 / 11009462 |

| MULTIFLEX 600 / 600-C | 2 – 20 AWG | Oil Res I/II, exposed run: TC-ER, PLTC-ER, ITC-ER, NFPA 79 | 62502 / 62556 |

4.11 Microbe-resistant control cables

Microbe-resistant control cables help inhibit the growth of bacteria and microorganisms. Typical applications include the F&B industry, cleanrooms, and environments that require strict hygiene compliance on production lines.

| Microbe-resistant control cable | Cross-sectional area (mm²) | Characteristics | Part number |

| KOMPOFLEX® JZ-500 / JZ-500-C | 0.5 - 50 | For use in waste recycling and composting plants, sewage treatment plants, car washes, laundries, in the chemical industry, in the food and beverage industry as well as breweries, animal stables and greenhouses | 26125 / 26217 |

| UNIPUR® / UNIPUR®-CP | 0.5 - 16 | Abrasion-resistant, flexible in cold temperatures | 18,120 / 19,150 |

| F-C-PURö-JZ | 0.5 - 6 | Oil resistant | 21200 |

Contact Information HELUKABEL Vietnam

| HELUKABEL Vietnam 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City, 700000, Vietnam | Phone:

+84 28 77755578 Email: info@helukabel.com.vn | Connect with us on |

| Order through our online channels Tiki | Shopee | Lazada | Product finder | ||