What are encoders? A glance at encoder cables and assemblies

In the rapidly evolving landscape of industrial automation, precision and reliability are key factors. Encoder cables play a critical role in ensuring smooth machine operation by providing accurate feedback signals, enabling control systems to monitor and regulate processes effectively.

-

1What are encoders?

-

2Applications of encoders

-

3Encoder classification: Incremental and absolute encoders

-

4What are encoder cables?

-

5Encoder cable features - Multi-channel signal

-

6Encoder cable features - Twisted pair structure

-

7Encoder cable features - Shielding layer

-

8Encoder cable features - Essential role in many applications

-

9Encoder cable connectors

-

10HELUKABEL encoder cable - Fixed installations

-

11HELUKABEL encoder cables - Moving applications

-

12Encoder cable assemblies acc. to Siemens standard

-

13Encoder cable assemblies acc. to Lenze standard

-

14Encoder cable assemblies acc. to Rockwell and Allen-Bradley

1. Understanding encoders

An encoder is a specialized type of sensor that collects positional information and transmits that data to other devices in the system.

1.1 What are encoders

In industrial control systems, an encoder is a specialized sensor designed to capture position information and transmit this data to other devices within the system. Position information can be determined using three main technologies:

- Optical

- Magnetic

- Capacitive

Regardless of the sensing technology used, the electronic circuitry inside an encoder is responsible for:

- Detecting motion

- Converting mechanical movement into industry-standard electrical signals used for measurement, monitoring, and control purposes.

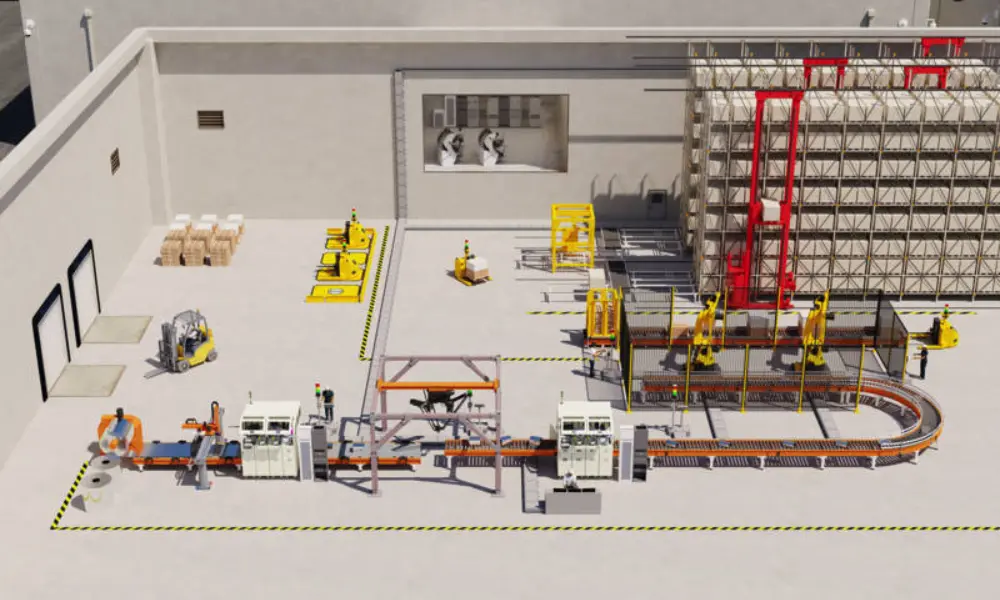

Encoders are used for various automation applications in factories.

1.2 Applications of encoders

Encoders are used to determine the position, speed, and direction of rotation of a motor shaft or other mechanical movements. They provide essential feedback information required for precise control in a wide range of applications, such as:

- Rotary table positioning

- Pick-and-place systems

- Machine assembly

- Packaging equipment

- Industrial robotics

- And many other automation applications

Regardless of the type, all encoders provide a method for detecting a reference or home position, which is used as a reference point for position control.

2. Types of encoders

Encoders are generally classified into two main types: incremental encoders and absolute encoders.

2.1 Incremental encoders

Incremental encoders typically generate a series of pulses in response to linear or rotary motion. These pulses can be used to measure speed or transmitted to a PLC or counter to track the relative position of the shaft.

The output signal of an incremental encoder is usually an electrical square-wave signal, with a frequency proportional to the rotational speed of the encoder shaft.

When powered on, an incremental encoder has no knowledge of the absolute position of the shaft; it can only determine how far the shaft has moved since the encoder began operating.

2.2 Absolute encoders

Absolute encoders generate a position value that directly represents the actual position of the encoder shaft. A major advantage of absolute encoders is that, in the event of a power loss, the encoder retains its position information - even if the shaft is rotated while power is off.

In addition, absolute encoders can also be used to calculate digital speed values. By internally computing the difference in position over a very short time interval, the encoder can accurately determine speed and transmit this information to downstream electronics such as PLCs, servo drives, or controllers.

In addition to common encoder types, there are specialized encoders such as tachometers, which are encoders with analog current outputs (0–20 mA or 4–20 mA). In these devices, the output signal is proportional to the shaft’s speed or position.

3. Characteristics of encoder cables

TOPGEBER 511 PVC encoder cable

Signal quality is a critical factor that determines the reliability of encoder operation. Therefore, selecting the right cable to meet the requirements of each application is essential. Encoder cables are designed to transmit the encoder’s output signals - which may include multiple signal channels to the control device (PLC, servo drive, controller…).

Although encoder cables typically operate unnoticed in the background of the system, they are an indispensable link in the data transmission chain between position sensors and control units. They ensure that information related to position, speed, and operating status is transmitted accurately, continuously, and reliably.

Since encoders often operate in industrial environments with high levels of electrical noise, encoder cables are engineered with specific technical characteristics that distinguish them from standard signal cables.

3.1 Multi-channel signal transmission in encoder cables

Encoder signals are not limited to a single transmission line. Instead, they often consist of multiple simultaneous channels, such as:

- A, B, Z pulse channels (incremental encoders)

- Data bits or communication signals (absolute encoders)

- Power supply and ground conductors

As a result, encoder cables are typically multi-core cables, with a well-structured internal design to ensure that different signal channels do not interfere with one another.

3.2 Twisted pair structure for EMI reduction

Most encoder cables use a twisted pair structure for signal transmission. This structure helps:

- Reduce inductive interference between conductors

- Minimize crosstalk between signal channels

- Maintain signal stability over long transmission distances

This is a key feature for preserving signal integrity.

In environments with extremely high levels of EMI, a basic twisted-pair structure alone may not be sufficient to prevent spurious pulses and signal distortion. In such cases, specialized cable constructions are required, incorporating shielding layers and mechanical strength members to ensure reliable signal transmission under harsh industrial conditions.

The shielding layer helps protect the encoder signal from external interference

3.3 Encoder cables are shielded

Encoder cables are typically equipped with EMI shielding, as they are often installed in parallel with power cables, motors, frequency inverters, servo drives, and other sources of electrical noise. Shielding protects encoder signals from external interference, ensuring that pulses are transmitted and received accurately.

Common shielding solutions include:

- Basic shielding solution: A combination of aluminum foil shielding and a drain wire. This provides a moderate level of noise protection and is suitable for cost-sensitive applications.

- Copper braided shielding: Ensures optimal performance for high-speed and high-frequency applications.

- Combined foil and braided shielding: For applications where EMI is a critical concern, the combination of both foil and braided shields delivers the highest level of noise protection and signal reliability.

3.4 A critical component in various industrial systems

Encoder cables play a vital role in many high-precision industrial systems, where encoders are used to provide real-time feedback on position, speed, and motion.

- Position control in robotics: Encoders are a core component in industrial robotics, enabling precise positioning of robotic arms. Encoder cables transmit real-time position feedback, allowing accurate movement control and smooth coordination in automated manufacturing processes.

- CNC machining: In CNC machining applications, encoder cables help ensure precise tool positioning, contributing to high-accuracy and high-quality machining results. Real-time position feedback allows continuous adjustment of tool paths, minimizing errors and improving machining quality.

- Conveyor systems: Encoder cables enable precise control of speed and positioning of items along production lines. This helps prevent bottlenecks, optimize material flow, and improve overall operational efficiency.

- Paper and printing industry: Encoder cables are used to control web tension and print register alignment. This ensures accurate printing and cutting processes, reduces material waste, and improves the quality of the final product.

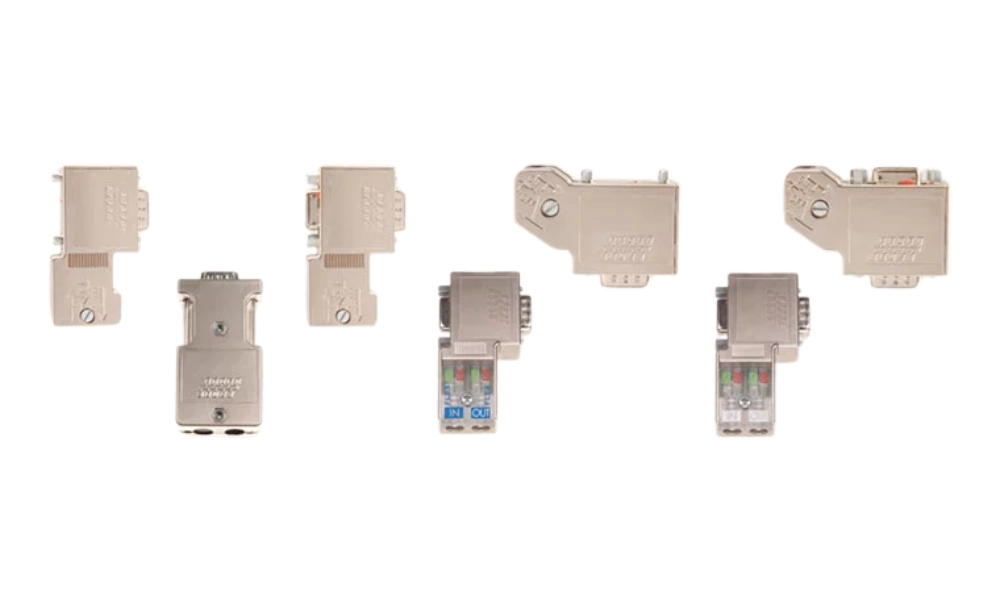

4. Encoder cable connectors

M12 circular connector

Connectors are widely used today, allowing users to easily disconnect and reconnect cables whenever required. During manufacturing, encoders are equipped with specific pin configurations designed to match a defined connector standard. A variety of connector types are used for encoder cables:

4.1 MS connectors

MS connectors feature a circular design with fine threads. This type of connector is suitable for encoder cables operating under harsh working conditions. However, it also has certain drawbacks, such as longer installation time and the risk of thread damage during handling or repeated installation.

4.2 M12 circular connectors

M12 circular connectors are designed with a quick-lock mechanism, making them easier to install compared to MS connectors. With a compact diameter of only 12 mm, they require minimal installation space. M12 connectors are commonly used with absolute encoders.

Profibus Plug SUB-D connector

4.3 M17 connectors

M17 connectors operate on a similar principle to M12 connectors. However, they are waterproof, easy to lock, and lightweight, making them well suited for use in wet or high-humidity environments.

4.4 M23 connectors

M23 connectors are designed for connecting rotary encoders to servo motors and electric motors in industrial systems. They offer robust protection and additionally allow signal transmission and power supply through the same cable assembly.

4.5 Bayonet connectors

Bayonet connectors help prevent incorrect cable-to-pin connections and provide simple and secure locking once the cable is inserted into the correct position. The locking principle is straightforward: the connection is secured by turning the connector clockwise by a quarter turn.

4.6 Sub-D connectors

Sub-D connectors are among the most compact connection solutions available. However, their mounting principle requires direct access to the encoder housing. Due to their relatively low protection level, Sub-D connectors are typically used in integrated systems where installation space is limited and environmental conditions are normal.

5. HELUKABEL’s encoder cable portfolio

Incremental Feedback encoder cable

HELUKABEL’s TOPGEBER encoder cables are specifically developed for continuous operation and applications requiring precise and uninterrupted position feedback. Designed for excellent noise immunity, high mechanical durability, and outstanding flexibility, TOPGEBER cables ensure reliable encoder signal transmission even in continuously moving systems, industrial robotics, CNC machines, and automated production lines.

5.1 Incremental encoder cables for fixed or not constantly movement applications

TOPGEBER 511 PVC cable has PVC outer sheath and is available in green (DESINA® standard) or orange, complying with the requirements of Siemens, Lenze, and Bosch Rexroth systems. This cable is used as a connecting cable for tachometers, brakes, and pulse generators in industrial equipment, machine tools, as well as control and automation systems.

Incremental Feedback-Cable is widely used in machinery construction, control equipment, and plant engineering due to their ability to transmit data and signals with high accuracy and reliability.

5.2 Encoder cables for moving applications

The following encoder cables are especially suited for continuous operation in drag chains, industrial robotics, and handling equipment, thanks to their ability to transmit data and signals with high accuracy and long-term stability.

- TOPGEBER 512 PUR: compatible with systems from Siemens, Bosch Rexroth, Lenze, Berger Lahr, B+R, Heidenhain, Baumüller.

- Incremental Feedback Cable-C-PUR: is designed to transmit control signals for positioning and operational characteristics. It is also used as a highly flexible connecting cable for tachometers, brakes, and pulse generators in applications subject to high mechanical stress in plant engineering, machine construction, and control and automation systems.

- Tachofeedback cable: are used for motor speed control and actual value measurement during operation.

6. HELUKABEL’s encoder cable assembly portfolio

Siemens encoder cable assembly - 6FX5002-2CA34

To ensure encoder signals remain stable, accurate, and reliable in automated systems, HELUKABEL’s pre-assembled encoder cables with connectors are developed as a complete, ready-to-install solution, designed for immediate operation across a wide range of working conditions.

HELUKABEL offers both static and dynamic versions, providing flexible solutions for fixed installations as well as continuously moving applications such as industrial robots, CNC machines, conveyor systems, and automated production lines. The cables are available with a wide variety of connector types, enabling easy integration into existing systems and ensuring compatibility with widely used standards from leading automation manufacturers, including Siemens, Lenze, Rockwell and Allen-Bradley.

6.1 Encoder cable assembly according to Siemens standard

| Manufacturer designation | Servo motor side | Cable | Controller side | |

| Static applications | 6FX5002-2DC30 | M12 | 2x2x0.22+2x0.38 | RJ45 IP20 |

| 6FX5002-2DD40 | RJ45 Cat5 | 2x2x0.22+2x0.38 | M17 | |

| 6FX5002-2CA34 | 17-pin signal connector | (3 × (2 × 0.14) + 4 × 0.14 + 4 × 0.22 + 2 × 0.5) | Speedtec signal coupling | |

| Dynamic applications | 6FX8002-2DC44 | M17 plug | 2x2x0.22+2x0.38 | M17 coupling |

| 6FX8002-2CA31 | 17-pin signal connector | (3 × 2 × 0.14) + 4 × 0.14 + 2.05 | 25-pin D-sub | |

| 6FX8002-2DC34-1ADO | M12 coupling socket | 2x2x0.20+2x0.38 | M12 signal plug pin | |

| 6FX8002-2DD44 | M17 Speedtec plug | 2x2x0.2+2x0.38 | M17 Speedtec plug coupling ready | |

| 6FX8002-2DC20 | RJ45 IP67 | 2x2x0.22+2x0.38 | RJ45 IP67 |

6.2 Encoder cable assembly according to Lenze standard

| Manufacturer designation | Servo motor side | Cable | Controller side | |

| Static applications | EWLRxxxGM-T | M23 threaded plug nut | (3x(2x0.14+2x0(5)) | 9-pin D-sub |

| EYF0018AxxxxF02S03 | M23 threaded plug nut | 4x(2x0.14)+(2x1.0) | 15-pin D-sub | |

| EYF0017AxxxxF01S02 | M23 | (4x2.5+(2x0.1)) | 9-pin D-sub | |

| Dynamic applications | EYF0020AxxxxA00S04 | 9-pin D-sub | 3x(2x0.14)+(3x0.14) | Open-ended |

| EYF0019AxxxxF02S03 | M23 plug | 4x(2x0.14)+2x(1.0) | 15-pin D-sub | |

| EYF0020AxxxxF01A00 | M23 plug | 3x(2x0.14)+(3x0.14) | Open-ended |

6.3 Encoder cable assembly according to Rockwell and Allen-Bradley standard

| Manufacturer designation | Servo motor side | Cable | Controller side | |

| Static applications | CFBM4D7-CD | M23, 17-pin plug | 15070025 | Open end |

| CFBM7DF-CD | M23, 17-pin plug | 15070025 | Open end | |

| CFBM4DD-CD | M23, 17-pin plug | 15070025 | D-Sub, 15-pin HD | |

| Dynamic applications | CFBM7E7-CE | M23, 17-pin plug | 15070027 | M23, 17-pin coupling |

| CFBM7DD-CE | M23, 17-pin plug | 15070027 | Sub, 15-pin, HD | |

| CFBM7DD-CD | M23, 17-pin plug | 15070026 | DSUB, 15-pin HD | |

| CFBM4DF-CO | M23, 17-pin plug | 15070026 | Open end |

6.4 Custom cable assembly solution

In addition to standard versions, HELUKABEL’s pre-assembled encoder cables with connectors can be customized to the required cable length, providing a flexible and optimized solution for specific applications - from new installations to system upgrades.

HELUKABEL offers customized solutions designed to ensure compatibility with a wide range of drive and automation systems upon request, including AMK, Baumüller, Panasonic, Schneider Electric, Mitsubishi, and others.

If you still have questions, don't hesitate to contact HELUKABEL Vietnam's team of engineers for detailed answers.

Contact Information HELUKABEL Vietnam

| HELUKABEL Vietnam 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City, 700000, Vietnam | Phone:

+84 28 77755578 Email: info@helukabel.com.vn | Connect with us on |

| Order through our online channels Tiki | Shopee | Lazada | Product finder | ||

_welcome_slider.png)