The meaning of bending radius for cables and drag chains

The bending radius is not only a reference parameter in technical design but also a critical criterion for ensuring cable performance and system safety. Let’s explore this technical specification across different types of cables and drag chains in the following article!

1. Understanding the bending radius and the minimum bending radius

1.1 What is the bending radius?

The bending radius is a technical specification that defines the radius at which an electrical cable can be bent without causing damage or impairing its functionality. The smaller the bending radius, the greater the flexibility requirements for the cable, and the more demanding its structural design needs to be.

This specification is usually expressed as a multiple of the cable’s diameter. For example: if a cable has a bending radius of 10 times its diameter, it means a cable with a diameter of 1 cm can be safely bent at a radius of 10 cm.

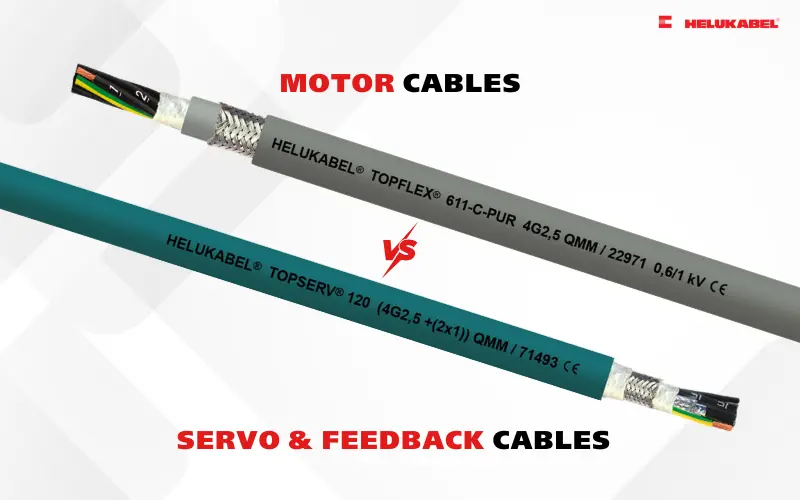

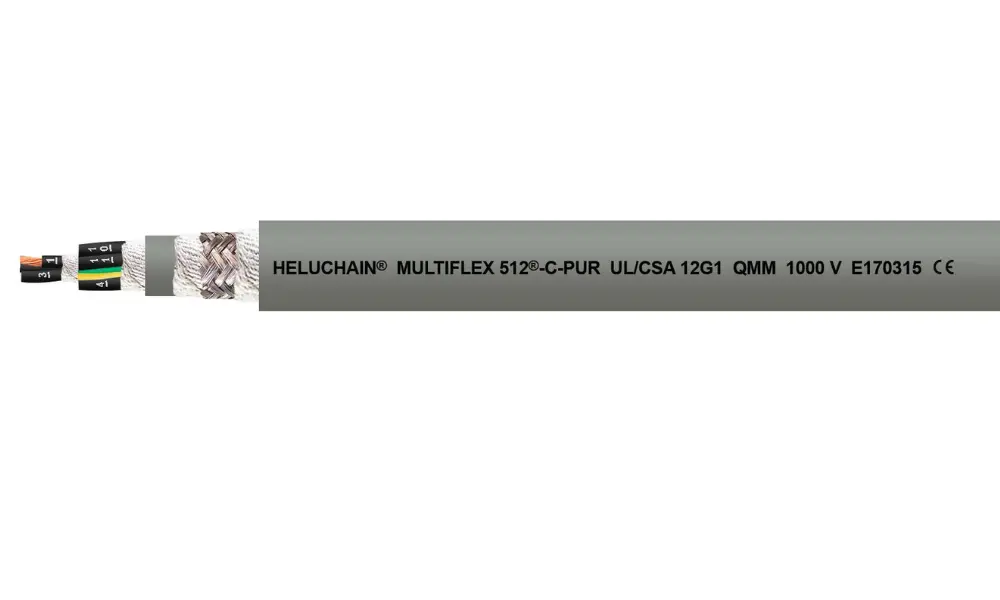

MULTIFLEX 512-C-PUR UL/CSA drag chain cable

1.2 Minimum bending radius

The minimum bending radius is the smallest radius at which a cable can be bent without causing damage. This parameter is typically specified as a multiple of the cable diameter. The smaller the value, the more flexible the cable.

There are many industrial standards that define the minimum bending radius for different cable types. These values vary significantly depending on whether the cable is used in fixed installations or dynamic applications. Each manufacturer specifies the minimum bending radius for their products, and users must ensure the correct bending radius is calculated according to the cable’s requirements.

For example: The MULTIFLEX 512-C-PUR UL/CSA cable has a minimum bending radius of 4 × d in fixed applications, but 7.5 × d in dynamic applications. The reason is that in continuous motion, the bending stress is significantly higher due to frequent changes in force and direction.

Therefore, selecting the appropriate minimum bending radius is a crucial criterion when choosing electrical cables and conductors.

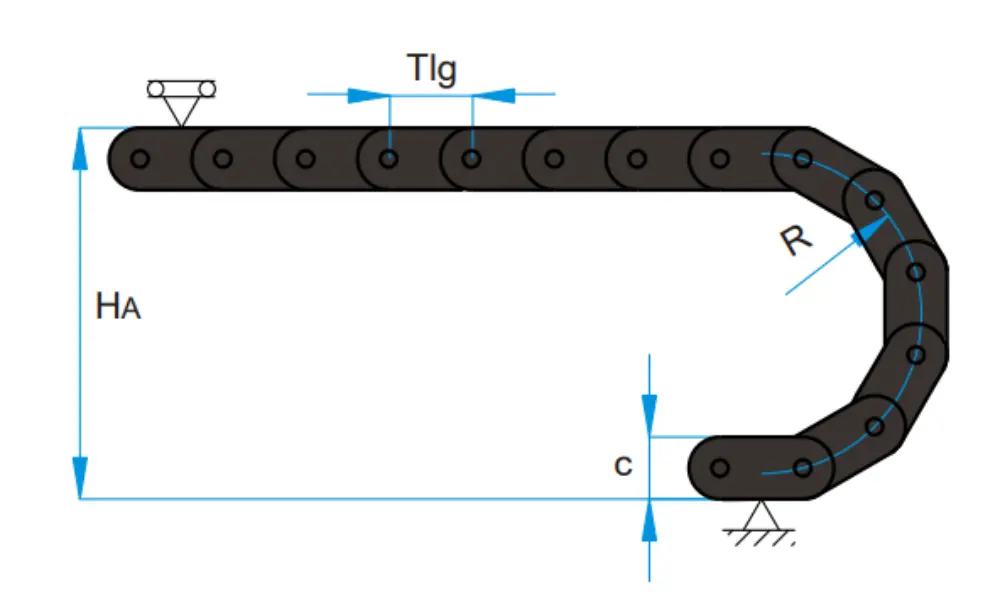

Bending radius in drag chains

1.3 Bending radius in drag chains

All types of drag chains are designed with different bending radius options to choose from – and each manufacturer provides recommendations for the minimum bending radius.

The bending radius of a drag chain is determined based on:

- The minimum allowable bending radius of the cables and hoses inside.

- The available installation space.

- Polygon oscillation (PA) of the chain.

In general, the minimum bending radius is taken as 10 times the largest outer diameter (10d) of the cable/hose. However, some manufacturers may supply cables that allow for a smaller bending radius.

>>See more: Drag chain selection made simple: 5 must-know basics

2. The importance of complying with the cable bending radius

When cables are installed with a bending radius smaller than the recommended value, the outer sheath may deform and expose the conductor

When cables are installed incorrectly with a bending radius smaller than the recommended value, the risks extend beyond cable damage and can also lead to operational and safety issues – both costly and hazardous:

- Sheath deformation: The outer sheath may deform and expose the conductor, making the cable more vulnerable to damage or failure.

- Increased signal loss: Electrical cables contain conductors and shielding layers to ensure signal integrity. Excessive bending places strain on these components, which may result in performance degradation or permanent damage.

- Electrical property deterioration: For power cables, sharp bends can increase resistance, leading to heat generation and reduced transmission efficiency. Excessive heat can accelerate insulation aging and, under extreme conditions, may even cause fire hazards.

- Physical damage: Over-bending can alter the cable’s geometry, resulting in crosstalk and higher electromagnetic interference (EMI). This causes data transmission errors and reduced network speeds. The issue is especially critical for high-frequency signals in modern Ethernet standards such as Gigabit Ethernet and 10-Gigabit Ethernet.

- Structured cabling systems: Maintaining the correct bending radius is particularly important in structured cabling systems. Data centers, offices, and industrial facilities often have complex infrastructures with large cable volumes. Any deviation from the recommended bending radius in such environments can trigger widespread network failures.

3. Factors affecting the bending radius of cables

Cable construction is the most important factor determining the bending radius

The bending radius of an electrical cable depends on various technical factors and environmental conditions. Understanding these factors helps in selecting the right cable for a specific application, while ensuring safety and durability during installation and operation.

3.1 Type of conductor

Cable construction is the most important factor determining the bending radius.

- Stranded conductor: Consist of multiple fine copper wires twisted together, making them flexible and easy to bend. These are commonly used in control cables, robotic cables, and other applications requiring high flexibility.

- Solid conductor: Consist of a single conductor core, which is more rigid and less flexible.

3.2 Insulation and sheath materials

The type of insulation and sheath material affects cable flexibility:

- Rigid materials such as PVC reduce flexibility, resulting in a larger bending radius.

- Flexible and elastic materials such as rubber, PUR, or Teflon (PTFE) allow smaller bending radii, suitable for continuous-motion applications.

Example: A control cable with a PUR sheath can bend flexibly inside industrial robots, while a solid conductor PVC-insulated power cable requires a much larger bending radius when installed in walls.

Ambient temperature directly impacts the flexibility of the cable sheath

3.3 Cable outer diameter

The bending radius is directly proportional to the cable’s outer diameter. The larger the cable’s diameter, the larger the bending radius required.

High-voltage power cables are large in size and require wide bending radii to prevent insulation cracks.

Signal cables or fiber optic cables have smaller diameters and can bend at tighter radii but still must comply with specifications to avoid signal loss.

3.4 Temperature conditions

Ambient temperature directly impacts the flexibility of the cable sheath:

Cold environments: Cables become stiff and brittle, requiring a larger bending radius to avoid sheath cracking.

Hot environments: Some cables become softer and easier to bend, but temperature limits must still be observed to prevent deformation or insulation melting.

The way and location of cable installation greatly influence the bending radius

3.5 Installation method

The way and location of cable installation greatly influence the bending radius.

- In conduits or cable trays: Limited space forces sharper bends, risking violation of the minimum bending radius.

- In complex systems (data centers, control cabinets): Horizontal, vertical, or multiple sharp bends require careful radius calculations.

- Suspended or long-distance installations: Require larger bending radii to reduce stress on the conductor.

3.6 Tensile stress on the cable

During installation, pulling forces acting on the cable must be controlled. Excessive pulling force can reduce the effective bending radius. For long cable runs, tensile stress increases with length, so proper installation techniques are essential.

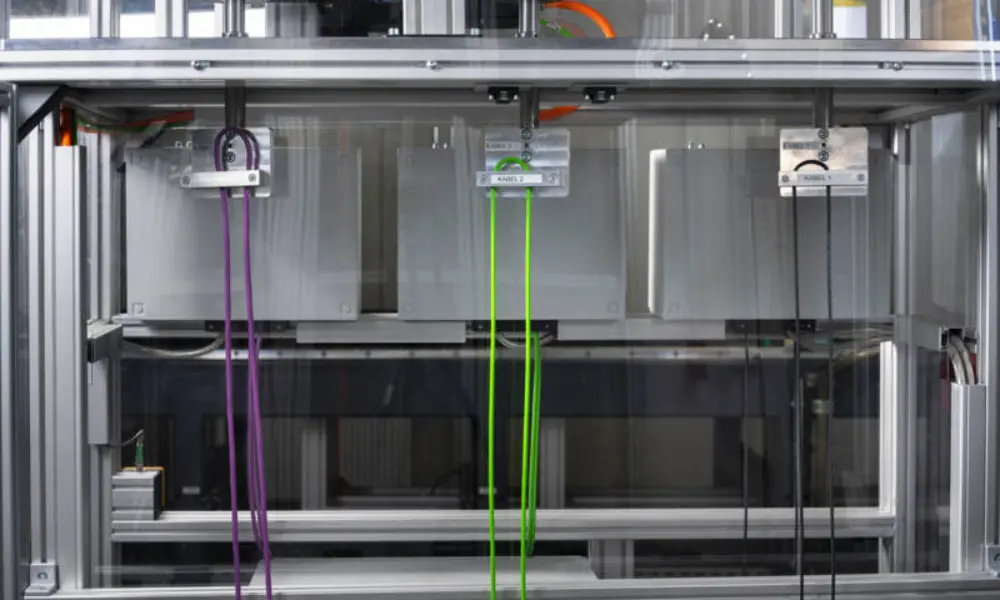

3.7 Application type and frequency of movement

The application determines the bending radius requirements:

- Fixed installation: For example, building wiring requires compliance with the minimum bending radius only once during installation.

- Dynamic or flexible applications: Such as industrial robots and automated machinery, where cables bend continuously. These cables require much smaller bending radii and are typically designed with ultra-fine stranded conductors and highly elastic outer sheaths.

For instance: HELUKABEL’s ROBOFLEX torsion-resistant cables used in robots can withstand several million bending cycles, whereas fixed installation cables would fail after just a few repeated bends.

4. Industry standards for cable bending radius

HELUKABEL cables undergo torsion tests at the factory in Windsbach

There are various industry standards and guidelines that help manufacturers and installers determine the appropriate bending radius for each type of cable. Compliance with these standards ensures safe installation and reliable operation.

4.1 NEC (National Electrical Code)

The NEC provides guidelines for electrical systems, including rules on cable bending radius. This standard is especially important, as improper bending can create serious safety risks.

4.2 TIA standards

The TIA establishes bending radius standards for both fiber optic and copper cables in telecommunications and data networks. These standards aim to minimize signal loss and maintain stable network performance.

4.3 IEC standards

The IEC issues international standards for electrical and electronic systems, including specifications for cable bending radii. These standards are particularly important for ensuring safety and compatibility in global installations.

4.4 Manufacturer recommendations

In addition to industry standards, each cable manufacturer provides specific recommendations for the minimum bending radius of their products. These guidelines must be followed during installation, as they are based on the unique structure and materials of each cable type.

5. Minimum bending radius specifications for HELUKABEL cables and drag chains

5.1 Minimum bending radius for HELUKABEL cables

At HELUKABEL, each type of electrical cable has a clearly defined minimum bending radius specified in the technical documentation. Customers can find detailed information in the HELUKABEL product catalogue or in the technical datasheets provided with each product to ensure proper and compliant installation.

| Cables | Name | Minimum bending radius (flexing) x d | Minimum bending radius (fixed) x d | Part no. |

| Drag chain | JZ-HF | 7.5 | 4 | 15001 |

| SUPER-PAAR-TRONIC-340-C-PUR | 7.5-10 | 4-5 | 49536 | |

| HELUCHAIN® MULTISPEED® 520-C-PVC UL/CSA | 6.8 | 4 | 11001602 | |

| Robot | HELUDATA® ROBOFLEX®-PAIR-D PUR UL/CSA | 10 – 12.5 | 5 | 11022463 |

| HELUCONTROL® ROBOFLEX®-D PUR UL/CSA | 10 – 12.5 | 5 | 11022437 | |

| HELUPOWER® ROBOFLEX® HYBRID PUR UL/CSA | 10 – 12.5 | 5 | 11022537 | |

| Ethernet | HELUKAT® 600T CAT.7 SF/FTP PUR TORSION | 15 | 8 | 805828 |

| HELUKAT® 250S CAT.6 CMG SF/UTP PVC CHAIN | 20 | 3 | 805658 | |

| HELUKAT® 250IND CAT.6 SF/FTP PVC STATIC | 15 | 12 | 11017904 | |

| Lift cables | TRAGO / Lift-2S / | 20 | x | 25091/25001 |

5.2 Minimum bending radius for HELUKABEL drag chains

| Type | Name | Minimum bending radius (mm) |

| Plastic | HELUCHAIN® PLASTIC LINK 1-PF | 75 - 300 |

| HELUCHAIN® PLASTIC LINK 2-KL | 15 - 400 | |

| HELUCHAIN® PLASTIC LINK 4-PK | 40 -500 | |

| HELUCHAIN® PLASTIC LINK 4-45 | 75 - 340 | |

| Steel | HELUCHAIN® STEEL LINK1-SF | 100 - 300 |

| HELUCHAIN® STEEL LINK 4-SL | 60 - 600 | |

| HELUCHAIN® STEEL LINK 4-GK | 200 - 700 | |

| Hybrid | HELUCHAIN® HYBRID LINK 4-PL | 75 - 500 |

6. FAQs about bending radius

6.1 Does the bending radius change under extreme temperature conditions?

Yes, it does. Ambient temperature is one of the key factors influencing a cable’s flexibility. The bending radius limit of an electrical cable is closely linked to its operating temperature range. The “minimum bending radius” specified by the manufacturer is always based on certain temperature conditions. If the cable is installed or operated outside this range, its quality and performance may deteriorate.

- Low temperatures: In extremely cold environments (e.g., cold storage facilities), the cable sheath becomes stiff and brittle, making it prone to cracking if bent too sharply.

- High temperatures: In hot and humid environments, or near furnaces and hot-rolling steel mills, the cable sheath may soften, deform, wear quickly, and lose mechanical strength.

To ensure safety and durability in extreme temperature conditions, HELUKABEL recommends using cables with PUR or TPE sheaths – two materials specially engineered to maintain flexibility and mechanical strength across a wide temperature range.

6.2 Is a smaller bending radius always better?

This is a misconception. Choosing a bending radius that is too small can damage the cable, increase the risk of failures, and result in unnecessary repair or replacement costs.

Many people assume that the more flexible a cable is, the tighter it can be bent, and therefore, a smaller bending radius is always better. In fact, every cable type has a manufacturer-specified minimum bending radius. If the cable is bent below this limit:

- The internal structure may be damaged.

- Cable lifespan is reduced.

- The risk of operational failures increases.

Therefore, instead of aiming for the smallest possible bending radius, users should always follow the manufacturer’s recommendations.

6.3 Do all cables have the same bending radius?

Not at all. Different cable types have different bending radius requirements, and in many cases, the differences can be significant. That’s why during design and installation, it is essential to follow the exact technical specifications provided by the manufacturer, rather than applying a one-size-fits-all rule.

Using a single bending radius standard for all cables can lead to problems such as:

- For power cables: Excessive bending may damage insulation, cause overheating, or even create short circuits and fire hazards.

- For data or fiber optic cables: An improper bending radius can lead to signal loss, reduced transmission speeds, and connection failures.

If you still have any concerns or questions, don't hesitate to reach out to HELUKABEL Vietnam's engineering team promptly for detailed assistance.

HELUKABEL® Vietnam

| Address | 905, Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City 700000, Vietnam |

| info@helukabel.com.vn | |

| Hotline | +84 28 77755578 |

| Website | www.helukabel.com.vn |

| Discover our products and place orders | Tiki | Shopee | Lazada | Product finder |

| Follow us on | Facebook | LinkedIn | Instagram | Youtube | Zalo | WhatsApp | Tiktok | Spotify |