What are medium voltage cables? Cables for infrastructure & building

Medium voltage cables have long played a critical role in modern electrical distribution systems. They are used to transmit electrical power from substations to a wide range of end users, including residential areas, commercial buildings, and industrial facilities. By doing so, they ensure a stable, reliable, and efficient supply of electricity to meet everyday power demands.

1. Overview of medium voltage

Medium voltage electricity serves as a bridge between low voltage and high voltage

1.1 What is medium voltage?

Medium voltage (MV) is typically defined as electrical systems operating within a voltage range of 1 kV to 35 kV. These systems serve as a bridge between low voltage (up to 1 kV) and high voltage (above 35 kV), and play a vital role in supplying power to large-scale facilities that require a stable and high-capacity energy supply.

Medium voltage systems are widely used for power distribution in industrial plants, large commercial complexes, and healthcare facilities, where a continuous and uninterrupted power supply is essential to ensure the safe and efficient operation of critical infrastructure.

1.2 The role of medium voltage

- Improved power distribution efficiency: Medium voltage systems enable electricity to be transmitted over longer distances with lower power losses compared to low-voltage systems. This is especially important for large facilities or with high energy demand.

- Support for high-load equipment: Many factories and large-scale facilities operate machinery and equipment that require substantial power. MV systems are capable of handling these loads efficiently, supplying power to HVAC systems, production lines, and specialized medical equipment.

- Operational flexibility: By using transformers and substations, medium voltage systems allow voltage levels to be stepped down to suit specific areas and applications. This ensures that each part of a facility receives the appropriate voltage, enhancing both operational efficiency and safety.

- Increased system reliability: Medium voltage power systems help stabilize the electricity supply and reduce the risk of power interruptions - an important factor in critical environments where downtime can result in significant economic loss or safety risks.

2. Understanding medium voltage cables

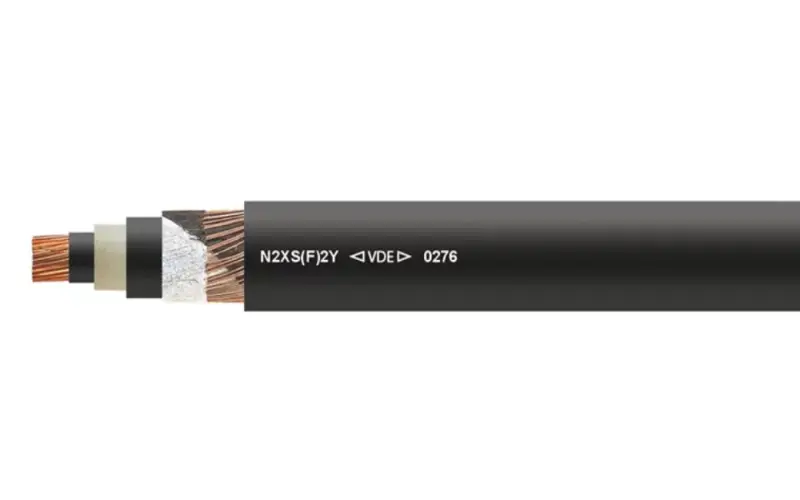

Medium-voltage power cable N2XSY

2.1 What are medium voltage cables?

A medium voltage cable is an insulated electrical conductor designed to transmit electrical power within a voltage range of 1 kV to 35 kV. Unlike low-voltage cables used in residential electrical systems or high-voltage lines used for long-distance power transmission, medium voltage cables serve as a critical link in the power distribution network. They are engineered to withstand environmental influences, mechanical stress, and electrical loads, ensuring stable and continuous power transmission.

According to the classifications of the International Electrotechnical Commission (IEC), medium voltage cables cover a relatively broad nominal voltage range, from 1 kV up to 100 kV. In practice, the actual voltage ratings of MV cables depend on the manufacturer and are most commonly found in the range of 3 kV to 69 kV. Notably, there is an overlap between medium voltage and high voltage cable ratings; for example, under IEC 60840, high voltage cables are rated from 30 kV to 150 kV.

Medium voltage cables play an essential role in urban infrastructure, industrial zones, and renewable energy projects. They enable the safe and efficient distribution of electricity from substations to end users, reduce power losses, and contribute to the overall stability and reliability of the electrical grid.

The structure of medium-voltage cables consists of multiple protective layers.

2.2 Structural characteristics of medium-voltage cables

Medium voltage cables typically consist of a conductor (made of copper or aluminum), multiple insulation layers, and an outer sheath. In many cases, additional shielding layers are incorporated to control electrical stress and reduce EMI.

- Conductor: copper and aluminum are commonly used

- Conductor screen: The conductor screen is a cross-linked semi-conducting compound extruded directly over the metallic conductor. Its function is to create a smooth and uniform interface between the conductor and the insulation layer, reducing localized electrical stress points that could otherwise compromise the long-term durability of the insulation.

- Insulation screen: The insulation screen is a cross-linked semi-conducting layer extruded over the insulation. It provides a smooth transition surface between the insulation - where the electric field is present - and the metallic screen - where the electric field is effectively zero. This layer helps to reduce electrical stress acting on the insulation.

- Metallic screen: The metallic screen typically consists of helically applied copper tape, often with an overlap, positioned over the insulation screen.

- Separation sheath: The separation sheath is applied over the cable core to isolate different metallic components, preventing galvanic corrosion and thereby extending the service life of the cable.

- Outer sheath: All medium voltage cables are provided with an extruded outer sheath made of PVC, MDPE, or LSZH compounds. The outer sheath - usually black in color - protects the cable against sunlight, termites, and environmental factors.

Some common applications of medium voltage cables

2.3 Applications of medium voltage cables

Thanks to their flexibility and high reliability, medium voltage cables are widely used for grid power distribution and power supply across a broad range of industries and sectors, including:

- PV systems: Medium voltage cables are an integral part of PV power systems. MV cables are the optimal solution for interconnecting power generation units within a solar project site and transmitting the generated electricity to the local substation.

- E-mobility: The growing adoption of electric vehicles (EVs) is expected to continue driving the expansion of the medium voltage cable market in the coming years. MV cables are essential for connecting commercial- and industrial-scale charging stations to the power grid and substations. In addition, medium voltage cables are also indispensable in railway electrification systems.

- Data centers: Data centers operate continuously on a 24/7 basis and consume large amounts of electrical energy. This demand will increase further with the advancement of AI technologies, which require more space and significantly higher power capacity for data processing.

- Industrial applications: Factories and manufacturing facilities rely on medium voltage cables to supply power to high-load machinery and process equipment. Large-scale systems such as cranes and conveyor systems also require medium voltage power supply due to their high energy demand. In these applications, voltage is increased to reduce current for the same cable size, allowing a reduction in the nominal conductor cross-sectional area while maintaining efficient power transmission.

3. Comparing low voltage, medium voltage, high voltage cables

| Low voltage cables | Medium voltage cables | High voltage cables | |

| Voltage | Below 1kV | 1kV – 35kV | 35kV and above |

| Applications | Residential and small commercial applications (LED lighting systems) | Industrial applications and large commercial projects (substations, power distribution networks, wind power, solar power) | Power plants, railway systems, medical and military sectors |

| Cable structure | Basic | Multi-layer structure with enhanced protection | Highly complex structure with special designs |

| Conductor | Copper or aluminum, high flexibility | Copper or aluminum, high flexibility | Copper or aluminum, high flexibility |

| Insulation | PVC, XLPE, rubber | Typically XLPE | XLPE and special material |

| Advantages | Safer to install and operate Flexible in design and installation | Lower power losses over medium transmission distances Suitable for higher load requirements | Excellent transmission efficiency Suitable for long-distance power transmission |

| Disadvantages | Not suitable for long-distance transmission Limited load capacity | More complex infrastructure Higher safety requirements during operation | Significant safety risks, requiring stringent protective measures High installation and maintenance costs |

The differences between low voltage, medium voltage, and high voltage cables are clearly defined:

- Low voltage systems are suitable for residential and general consumer applications, offering advantages in terms of safety and energy efficiency.

- Medium voltage systems strike a balance between power capacity and safety, making them widely used in commercial buildings and industrial facilities.

- High voltage systems focus on delivering large amounts of power, enabling efficient long-distance electricity transmission. However, they require stringent safety measures in design, installation, and operation to ensure secure and reliable performance.

4. IEC 60502-2 standard for medium voltage cables

IEC 60502-2 is an international standard applicable to medium voltage cables used in power generation networks, distribution networks, and certain transmission system applications.

This standard defines the various cable constructions, materials, and mandatory testing requirements to ensure that manufactured cables fully comply with the specified technical performance and safety criteria.

IEC 60502-2 is often regarded as the “umbrella standard” for medium voltage cables, as it covers most existing MV cable designs, including:

- Five nominal voltage ratings, up to 36 kV

- Single-core and three-core medium voltage cables

- Metallic screens in the form of tapes, braided screens, wires, or combinations of wires and tapes

- Armored and unarmored medium voltage cables

- Wire armor and tape armor constructions

- Medium voltage cables with or without lead sheaths

- Medium voltage cables with or without water-blocking protection

In addition, depending on specific market requirements, national standards may also apply, such as BS 6622, BS 7835, BS 7870-4.10, BS 7870-4.20 (UK), TCVN (Vietnam), DIN VDE (Germany)…

5. Features of HELUKABEL medium voltage cables

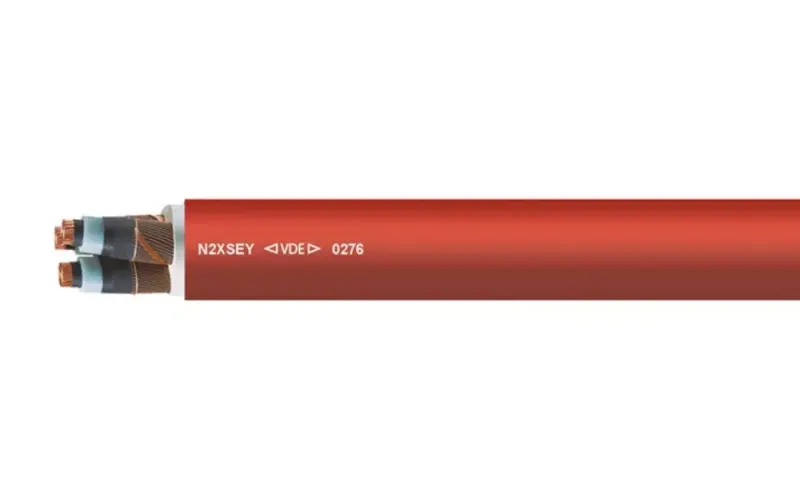

Cross-section of the layers of the N2XSEY medium voltage cable

5.1 General characteristics of HELUKABEL medium voltage cables

HELUKABEL medium voltage cables are designed and manufactured in accordance with internationally recognized standards such as IEC 60502, fully meeting the stringent requirements of modern power distribution systems.

These cables use high-quality copper or aluminum conductors, combined with cross-linked XLPE insulation, delivering excellent dielectric properties, low electrical losses, and outstanding resistance to heat, mechanical stress, and chemical influences.

The cable construction is optimized with semiconductive layers, metallic screening, longitudinal moisture protection, and a robust outer sheath (PVC, PE, or LSZH). This design ensures stable and reliable operation under harsh environmental conditions, suitable for both fixed installations and demanding industrial applications.

With high transmission efficiency, long-term reliability, and extended service life, HELUKABEL medium voltage cables are an ideal solution for power distribution networks, industrial zones, urban infrastructure, and renewable energy projects.

5.2 Construction features of HELUKABEL medium voltage cables

- Conductor: Made of copper or aluminum, round in shape, with a compact stranded construction.

- Inner semiconducting layer: Cross-linked semiconducting compound, extruded directly over the conductor, with a minimum thickness of 0.3 mm.

- Insulation layer: XLPE insulation using DIX8 compound in accordance with HD 620 S2, providing excellent dielectric performance, high thermal resistance, and long service life. The nominal insulation thickness depends on the voltage rating, ranging from 3.4 mm to 8.0 mm.

- Outer semiconducting layer: Cross-linked semiconducting compound with a thickness from 0.3 mm to 0.6 mm, ensuring stable electric field control and distribution.

- Conductor concentricity: The difference between the maximum and minimum concentricity values does not exceed 0.5 mm, ensuring uniform insulation thickness and enhanced operational reliability.

- Semiconducting tape: Applied over the outer semiconducting layer, this tape further improves electric field control and enhances dielectric stability.

- Screen: The screening layer consists of copper wires with a minimum diameter of 0.5 mm, over which a helically applied copper tape with a minimum thickness of 0.1 mm is added.

- Separator: A separating layer (e.g. a wrapping tape) is placed between the screen and the outer sheath.

- Outer sheath: Made of PE (black) or PVC (red).

6. Classification of HELUKABEL medium voltage cables

HELUKABEL offers a comprehensive portfolio of medium voltage cables designed to meet the diverse requirements of infrastructure and construction projects.

6.1 Copper conductor medium voltage cables

HELUKABEL’s copper conductor medium voltage cables are manufactured with XLPE insulation and fully comply with VDE standards and IEC 60502 requirements.

Certain MV cables are also classified under CPR fire performance classes such as Fca or Cca, making them suitable for different installation environments.

| Cable | Characteristics | CPR class | Part number |

| N2XSY | 6/10 kV, 12/20 kV, 18/30 kV, PVC sheath | Fca | 32400 |

| N2XS(F)2Y | 6/10 kV, 12/20 kV, 18/30 kV, PE sheath, longitudinally waterproof | Fca | 32560 |

| N2XS2Y | 6/10 kV, 12/20 kV, 18/30 kV, PE sheath | Fca | 32480 |

| N2XSEY | 3 x ... 6/10kV, PVC sheath | N/A | 34339 |

| N2XS(FL)2Y | 6/10 kV, 12/20 kV, 18/30 kV, PE sheath, longitudinally and laterally waterproof, direct burial | N/A | 33054 |

| N2XSH | 6/10 kV, 12/20 kV, 18/30 kV, halogen-free | Cca | 11023707 |

6.2 Aluminum conductor medium voltage cables

| Cable | Characteristics | CPR class | Part number |

| NA2XS(F)2Y | 6/10 kV, 12/20 kV, 18/30 kV, PE sheath, longitudinally waterproof | Fca | 32600 |

| NA2XS2Y | 6/10 kV, 12/20 kV, 18/30 kV, PE sheath, direct burial | Fca | 32520 |

| NA2XS(FL)2Y | 6/10 kV, 12/20 kV, 18/30 kV, PE sheath, longitudinally and laterally waterproof | N/A | 38062 |

| NA2XSY | 6/10 kV, 12/20 kV, 18/30 kV, PVC sheath | N/A | 32440 |

Medium-voltage cables are also used for photovoltaic systems.

6.3 Medium voltage cables for PV systems

In large-scale solar power projects, particularly solar farms, BESS (Battery Energy Storage Systems), and integrated DC/AC substations - medium voltage cables play a critical role in transmitting power from inverters and transformers to the utility grid or energy distribution centers.

Medium voltage cables used in solar applications are specifically engineered to handle high power transmission, minimal electrical losses, and stable long-term operation, even under continuous load and demanding environmental conditions typical of outdoor renewable energy installations.

Typical HELUKABEL medium voltage cable types for solar power projects include: N2XS2Y, N2XS(F)2Y, NA2XS2Y, NA2XS(F)2Y, NA2XS(FL)2Y

6.4 Medium-voltage power cables for data centers

Data centers rely on the building's critical technical infrastructure to ensure continuous 24/7 operation. HELUKABEL provides specialized cable solutions and connectivity technology designed to operate reliably in demanding operational environments such as:

- Backup generator and emergency power system

- Mechanical rooms and HVAC systems

- Cooling and fire suppression system

- Security and surveillance system

- Building lighting and automation systems

- Energy management and grid connection

Some representative products include MV90-15kV AL 133 IL, MV90-35kV CU 133 IL

Explore the catalog of cables and accessories for data centers

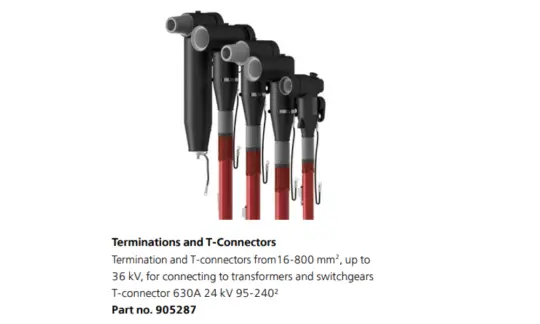

6.5 Medium voltage cable accessories

In any medium voltage cable system, cable accessories are not optional components - they are essential elements that ensure the safe, reliable, and long-term operation of the entire power network. Accessories used for jointing, connecting, and terminating MV cables have a decisive impact on electrical performance, system lifespan, and future maintenance costs.

Cable joints are used to connect two cable lengths during installation, system expansion, or repair works. HELUKABEL supplies heat-shrink and cold-shrink medium voltage joints suitable for both single-core and three-core MV cables, providing secure electrical continuity, excellent insulation performance, and long-term operational stability. These jointing solutions are designed for rated voltages up to 36 kV.

Cable terminations are used to connect medium voltage cables to electrical equipment such as transformers, switchgear, and MV panels. HELUKABEL’s range of MV terminations and T-connectors is engineered to meet demanding industrial requirements, with typical specifications including 630 A at 24 kV for conductor sizes 95–240 mm², and 36 kV solutions for cable cross-sections from 16 up to 800 mm².

If you still have questions, don't hesitate to contact HELUKABEL Vietnam's team of engineers for detailed answers.

Contact Information HELUKABEL Vietnam

| HELUKABEL Vietnam 905 Nguyen Kiem Street, Hanh Thong Ward, Ho Chi Minh City, 700000, Vietnam | Phone:

+84 28 77755578 Email: info@helukabel.com.vn | Connect with us on |

| Order through our online channels Tiki | Shopee | Lazada | Product finder | ||